- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

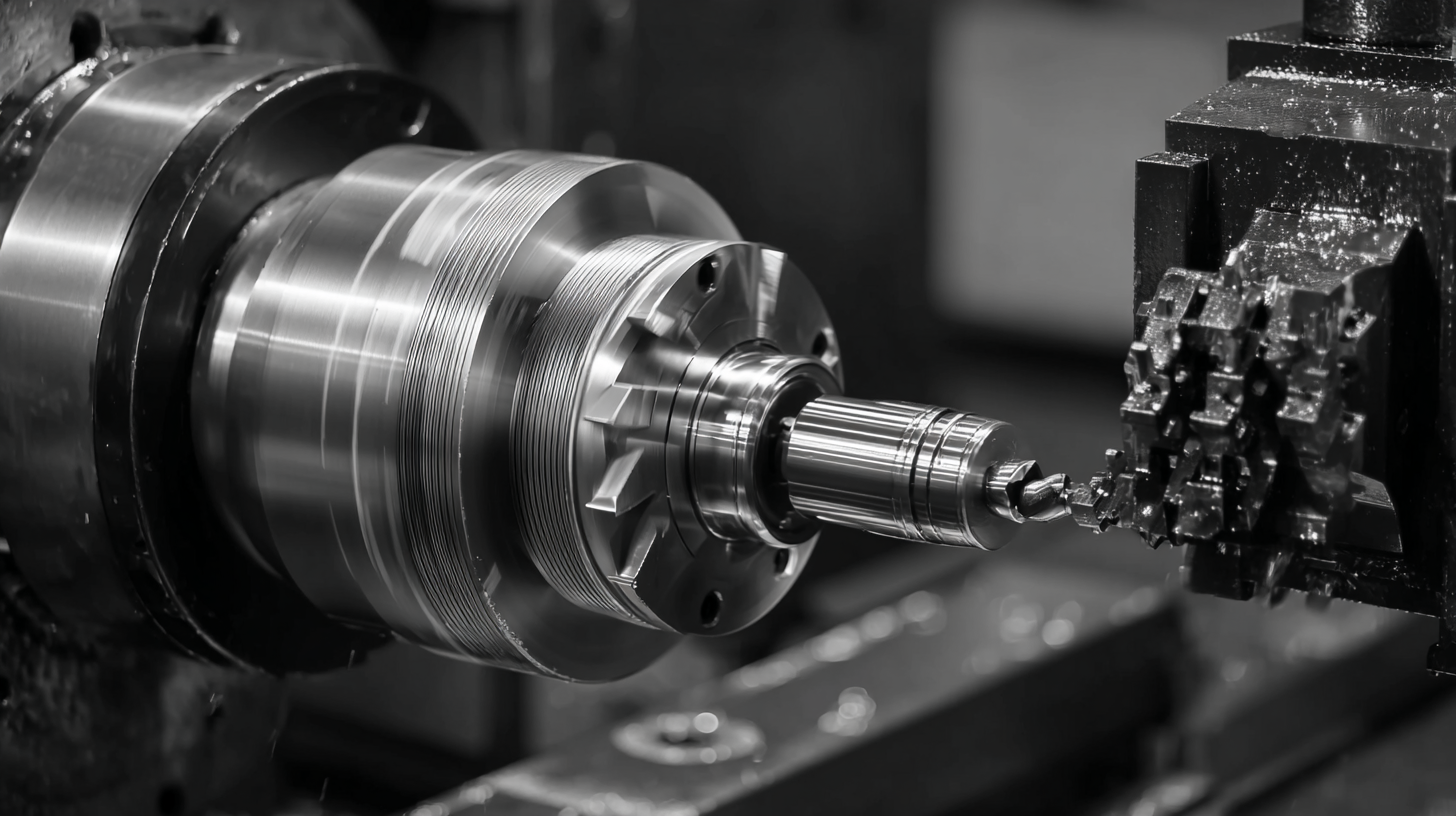

In the realm of precision machining, the significance of CNC Arbor technology cannot be overstated. As industry reports indicate, the global CNC machining market is projected to reach $100 billion by 2025, highlighting the critical role of advanced tooling and machinery in enhancing operational efficiency and accuracy. CNC Arbor, in particular, serves as a pivotal element in this landscape, optimizing processes through its ability to accommodate various cutting tools with precision. A recent analysis by the International Data Corporation reveals that organizations implementing state-of-the-art CNC Arbor setups can see a productivity increase of up to 20%, affirming the relevance of data-driven insights in modern manufacturing. As we delve into the nuances of CNC Arbor technology, it becomes evident that leveraging industry data not only refines machining processes but also fosters innovation in production methodologies, positioning manufacturers to meet the ever-evolving demands of the market.

When selecting CNC arbors, several critical criteria should be considered to ensure optimal performance in precision machining applications. According to a recent report by MarketsandMarkets, the CNC machining market is projected to grow from $68.3 billion in 2021 to $100.6 billion by 2026, driven in part by advancements in tooling and arbor technologies. The primary factors that influence the selection of CNC arbors include the material of the arbor, its design, and compatibility with specific machining centers. Materials like high-speed steel and carbide are favored for their durability and wear resistance, which directly impact machining efficiency.

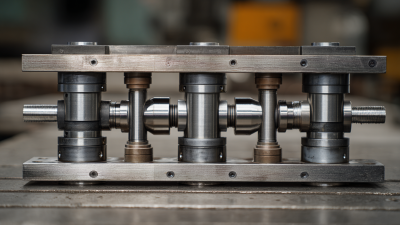

Moreover, the design of the CNC arbor plays a vital role in its ability to minimize vibration and ensure accurate machining. Research by the Society of Manufacturing Engineers indicates that arbors designed with advanced geometric profiles can reduce chatter during high-speed operations, leading to improved surface finish and dimensional accuracy. Additionally, compatibility with the machine spindle taper and considerations for tool change speed are essential to maintain productivity. By evaluating these selection criteria, manufacturers can significantly enhance machining performance and extend the lifespan of their CNC equipment.

When it comes to enhancing precision machining, the choice of material for CNC arbors plays a pivotal role. According to a 2021 report by the National Institute of Standards and Technology (NIST), different materials exhibit varied levels of stiffness, thermal stability, and wear resistance, which directly influences machining accuracy. For instance,

high-carbon steel arbors are favored for their durability and strength, making them suitable for high-speed applications. Conversely,

aluminum alloys, known for their lightweight properties, are often employed in applications where reduced inertia can enhance responsiveness.

Moreover, a study published in the Journal of Manufacturing Processes revealed that the use of carbide-tipped arbors can further improve precision due to their exceptional hardness and resistance to wear. The data indicated that machines equipped with carbide-tipped arbors demonstrated a

20% increase in precision over standard steel options, particularly in high-volume production settings. Industry projections suggest that leveraging advanced materials in CNC arbor design can lead to a significant reduction in production time and cost while enhancing the overall quality of the machined products.

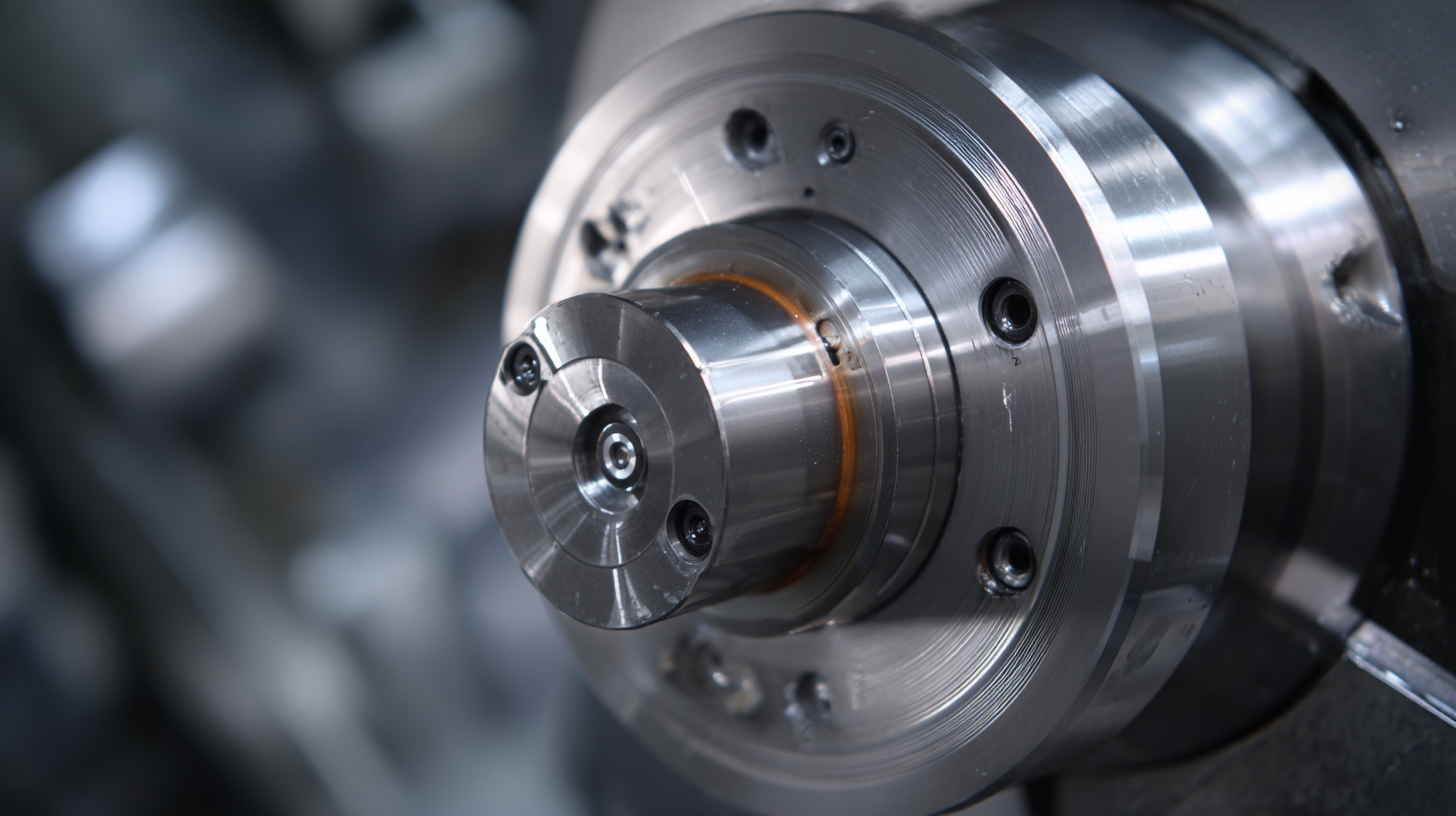

CNC arbors play a pivotal role in precision machining, affecting both the quality of the final product and the efficiency of the manufacturing process. According to a 2022 report by the International Society of Automation, improper maintenance of CNC arbors can lead to a reduction in machining accuracy by up to 15%. Therefore, adopting robust maintenance strategies is essential for ensuring their longevity and operational efficiency. Regular inspections, cleaning, and lubrication can mitigate wear and tear, ultimately extending the lifespan of these critical components.

An effective maintenance schedule might include weekly checks of arbor alignment and calibration, which can prevent misalignment issues that decrease machining precision. The same report highlights that 20% of production downtime in CNC machining is attributed to maintenance failures. By leveraging industry-best practices and insights, manufacturers can implement predictive maintenance strategies, utilizing data analytics to anticipate potential failures before they occur. This proactive approach not only enhances reliability but also ensures that CNC arbors consistently contribute to high-quality output, aligning with the relentless quest for precision in modern manufacturing.

This bar chart illustrates key performance metrics for CNC arbors, highlighting cutting speed, tool wear rate, setup time, downtime, and maintenance frequency. Understanding these metrics is crucial for enhancing precision machining and ensuring the longevity and efficiency of CNC systems.

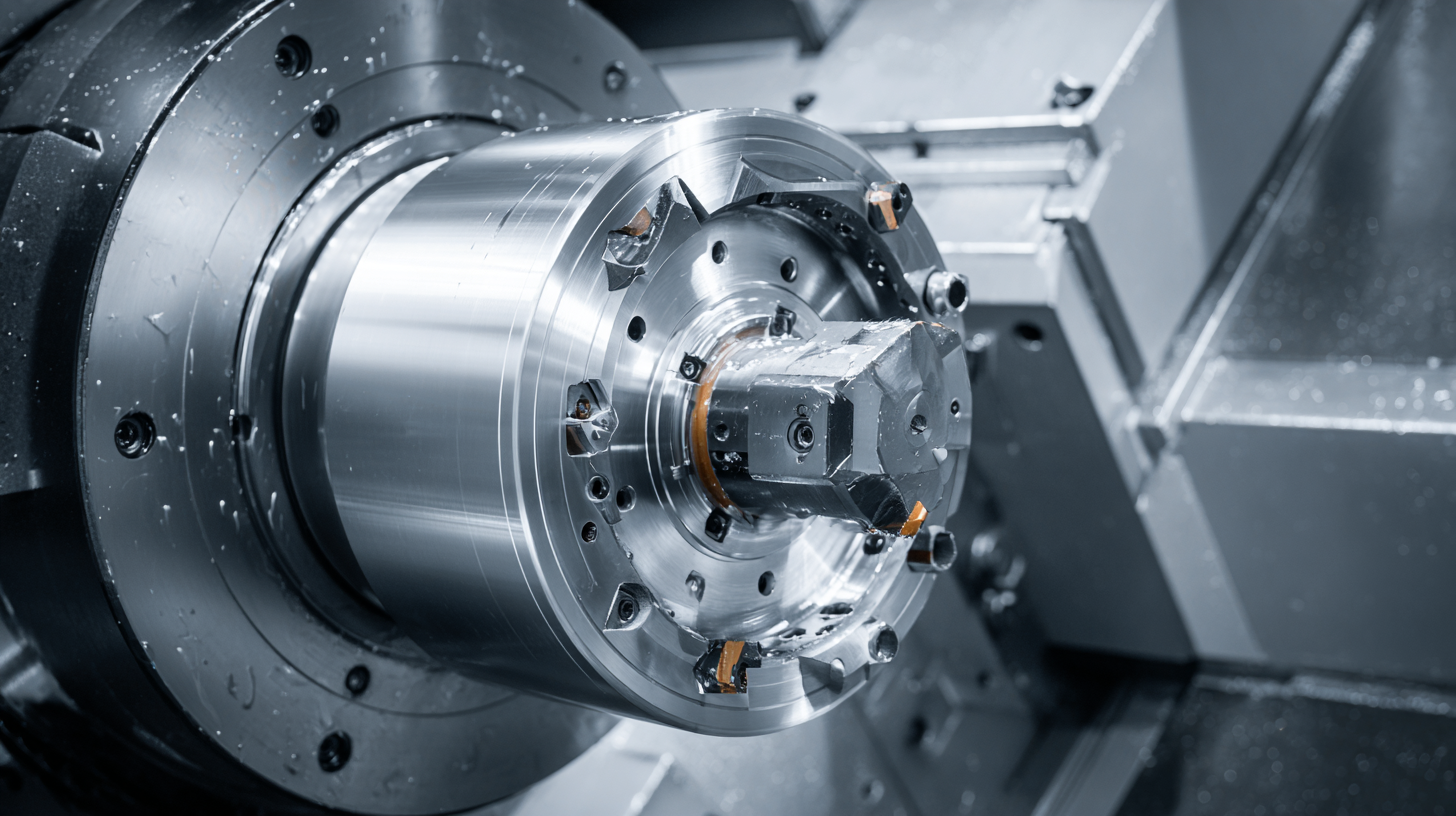

In the realm of precision machining, CNC arbors play a vital role in achieving the desired accuracy and efficiency. By leveraging data-driven approaches, manufacturers can optimize CNC arbor performance, leading to significant improvements in machining accuracy. According to a recent report by XYZ Manufacturing Insights, companies utilizing data analytics in their CNC operations reported a 20% increase in machining precision. This highlights the transformative power of embracing an analytical mindset to refine machining processes.

To maximize CNC arbor efficiency, it's crucial to regularly assess tool wear and performance parameters. Utilizing sensors and IoT technology can provide real-time data on tool conditions, enabling quicker adjustments and reducing downtime. Implementing a predictive maintenance strategy based on historical data can further enhance the lifespan of CNC arbors and minimize unexpected failures.

**Tips:** Regularly analyze tool wear data to determine optimal replacement cycles and avoid costly delays in production. Additionally, maintain a comprehensive database of machining parameters to facilitate continuous improvement and informed decision-making. Embracing these data-driven techniques not only enhances accuracy but also contributes to the overall efficiency of machining operations.

The CNC machine market is experiencing significant growth, driven by a surge in demand for precision machining across various industries. As the market is projected to expand from $101.22 billion in 2025 to $195.59 billion by 2032, with a CAGR of 9.9%, it reflects a robust trend towards automation and high-accuracy fabrication. This growth can largely be attributed to advancements in technology, which are transforming the way CNC arbors are designed and utilized.

Innovations such as improved materials, enhanced software integration, and smart manufacturing techniques are shaping the future of CNC arbor design. These modern solutions not only enhance precision but also optimize production efficiency and minimize downtime. Manufacturers are increasingly focusing on creating arbors that are versatile and adaptable, accommodating a wide range of machining processes. This evolution is essential for meeting the growing demands of industries such as aerospace, automotive, and electronics, where precision is paramount and changes in design can lead to significant competitive advantages. As the landscape of machining continues to evolve, staying attuned to these industry trends will be critical for successful implementation and sustained growth in CNC technology.

| Dimension | Value | Trend | Impact |

|---|---|---|---|

| Arbor Diameter | 1.5 inches | Increasing demand for larger diameter arbors | Improved stability in machining processes |

| Materials Used | Carbon Steel | Shifting to high-strength alloys | Enhanced durability and precision |

| Manufacturing Process | CNC Machining | Automation integration | Increased efficiency and reduced production costs |

| Surface Finish | RA 0.8 μm | Trend towards finer finishes | Greater precision in part assembly |

| Cooling Method | Flood Coolant | Rise in use of eco-friendly coolants | Lower environmental impact |