- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

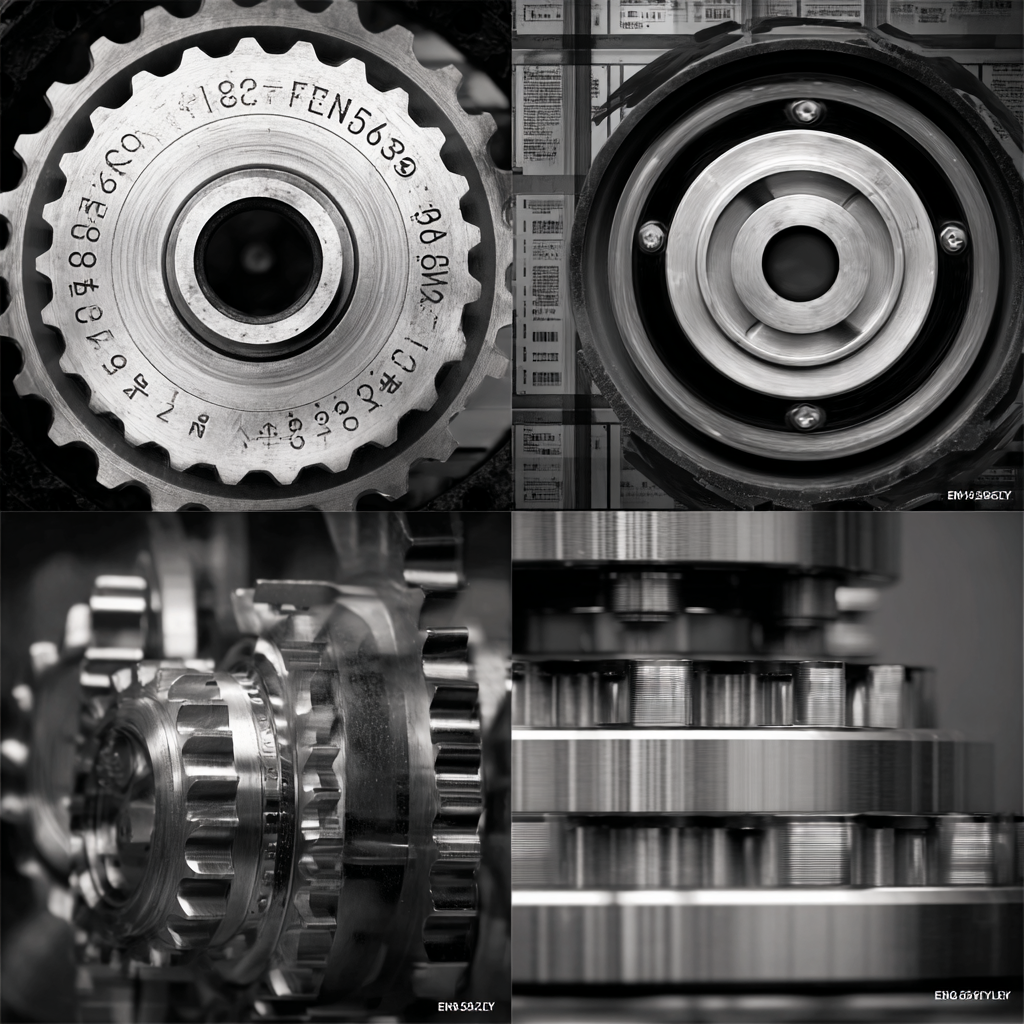

In the realm of precision engineering, the significance of CNC flywheels cannot be overstated. As we approach 2025, advancements in technology promise to further refine the manufacturing processes and enhance the capabilities of CNC flywheels, making them a cornerstone in various applications, from automotive to aerospace. This guide aims to delve into the intricacies of CNC flywheels, shedding light on their design, functionality, and the latest innovations that are shaping the industry.

With the growing demand for efficiency and accuracy, understanding the essential features and specifications of CNC flywheels is crucial for engineers and manufacturers alike. In this ultimate guide, we will explore the best practices for selecting, designing, and implementing these sophisticated components, ensuring that users are well-equipped to make informed decisions. From material selection to machining techniques, we will provide comprehensive insights that cater to both seasoned professionals and newcomers to the field.

CNC flywheels play a pivotal role in precision engineering, offering numerous key features and benefits that enhance manufacturing processes. One of the primary advantages of CNC flywheels is their ability to achieve high levels of precision, which is crucial for applications where minute tolerances can significantly impact performance.

With advanced CNC machining technologies, manufacturers can produce components with consistent quality, minimizing the risk of errors and ensuring that every piece meets stringent specifications.

With advanced CNC machining technologies, manufacturers can produce components with consistent quality, minimizing the risk of errors and ensuring that every piece meets stringent specifications.

Additionally, the flexibility of CNC flywheels allows for custom component manufacturing, catering to various specialized applications. The integration of modern tube cutting technology further exemplifies how precision engineering is evolving; this technology enables more efficient material handling and processing, which is essential for meeting increasing demands in the global market.

As industries increasingly recognize the importance of high-quality components, the expansion of CNC machining services, including enhanced materials and techniques, will continue to reshape the landscape of manufacturing, driving innovation and improving productivity.

In the realm of precision engineering, CNC flywheels have emerged as pivotal components in various applications, from automotive to aerospace. As we enter 2025, several manufacturers have distinguished themselves by consistently delivering top-quality CNC flywheels designed to optimize performance and durability. The following overview highlights the top ten CNC flywheel manufacturers making significant strides in the industry.

Among these leaders, Company A stands out for its innovative design techniques and state-of-the-art machinery, ensuring precision at every stage of production.

Company B has garnered a reputation for its exceptional quality control processes, allowing them to produce flywheels that meet stringent industry standards.

Meanwhile, Company C excels in customization, providing tailored solutions that cater to specific client needs. These manufacturers exemplify the advancements in CNC technology, illustrating the best practices in the production of flywheels that drive efficiency and effectiveness across various sectors.

Their commitment to excellence sets a benchmark for others in the industry, reflecting the evolving landscape of precision engineering.

The competitive landscape of CNC flywheels in 2025 showcases significant advancements in precision engineering, with leading manufacturers focusing on performance metrics that matter most to engineers and machinists. Key attributes such as dimensional accuracy, weight consistency, and rotational stability have emerged as crucial indicators of a flywheel’s effectiveness. Notably, high-end CNC flywheels are optimized using cutting-edge materials, reducing vibrations and improving overall efficiency.

Comparative analysis among the top models reveals substantial variations in performance, particularly in terms of power transfer and energy storage capabilities. For example, some manufacturers have developed composites that not only enhance durability but also contribute to a lower moment of inertia, facilitating quicker spin-up times and better responsiveness in dynamic environments. Additionally, integrating smart technology for real-time monitoring of performance metrics has become a defining feature for many of the leading flywheels, providing users with actionable insights to optimize machinery operations further. Such innovations highlight the continuous evolution of CNC flywheels and their critical role in precision engineering applications.

As the demand for precision engineering increases, CNC flywheel design is evolving with innovative technologies that enhance the accuracy and efficiency of manufacturing processes. Recent industry reports indicate that the global CNC machine tools market is expected to reach $100 billion by 2025, driven by advancements in smart manufacturing and automation. Techniques such as adaptive machining and real-time monitoring using IoT technologies are optimizing the production of flywheels, ensuring tighter tolerances and improved performance.

CNC flywheels are revolutionizing various industries through their precision engineering solutions. In the automotive sector, for instance, these components enhance engine performance by optimizing power delivery and reducing vibrations. Advanced CNC machining techniques enable manufacturers to produce flywheels with exact specifications, resulting in improved fuel efficiency and reduced emissions. As a result, automotive engineers increasingly rely on CNC flywheels to enhance the overall reliability and performance of their vehicles.

In addition to automotive applications, CNC flywheels are gaining traction in aerospace and manufacturing industries. The lightweight yet sturdy design of CNC-machined flywheels allows for superior energy storage and transfer, making them ideal for applications requiring high rotational speeds. Aerospace engineers use these flywheels in various systems, including propulsion and energy management, where precision and weight savings are critical. Moreover, the manufacturing sector benefits from CNC flywheels in automation and robotics, where they contribute to smoother motion and increased energy efficiency. The adaptability and precision of CNC flywheels are propelling advancements across these industries, showcasing the profound impact of advanced engineering solutions.