- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

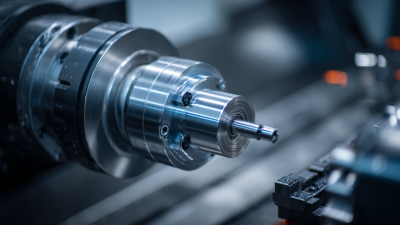

In the world of manufacturing, Cnc Bolts play a crucial role in ensuring precise assembly and reliability. Expert John Smith, a seasoned engineer in the CNC industry, once said, "The quality of your bolts can make or break your project." This highlights the importance of selecting the right Cnc Bolts for various applications.

Cnc Bolts come in many shapes and sizes, each designed to fulfill specific requirements. Whether you are working on automotive, aerospace, or home projects, understanding their differences is vital. For instance, titanium bolts are lightweight yet strong, making them ideal for high-performance applications. However, some may overlook the need for proper maintenance and care, resulting in corrosion over time.

Choosing Cnc Bolts demands careful consideration. Many users may choose based solely on cost, neglecting quality. This common mistake could lead to project failures. The challenge is to balance affordability and reliability. Amidst numerous options, knowing the top 10 Cnc Bolts can enhance your decision-making, ensuring that every assembly achieves optimal performance.

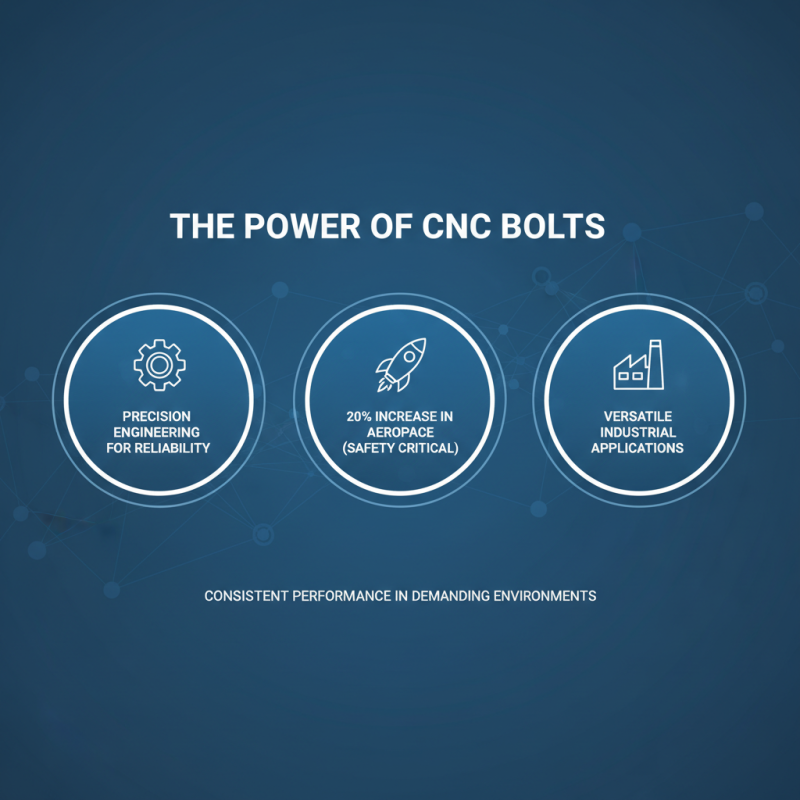

CNC bolts play a crucial role in various applications across industries. These fasteners are designed with precision, allowing for consistent performance in demanding environments. According to industry reports, the use of CNC bolts has increased by 20% in the aerospace sector alone. This spike highlights their importance for safety and reliability.

Applications of CNC bolts extend into automotive, construction, and electronics fields. In automotive manufacturing, they secure essential components. The reliability of these bolts is crucial; a single failure can lead to significant operational risks. The electronics industry also benefits from CNC bolts, especially in compact devices where every millimeter counts. However, challenges remain. Variations in material quality and tolerances can lead to failures.

Data shows that nearly 15% of field failures in machinery are due to inadequate fastening. This statistic raises questions about current production standards. Ensuring that CNC bolts meet strict specifications is vital. Companies must regularly assess their quality control processes to prevent costly mistakes. Making improvements in manufacturing can save time and resources in the long run.

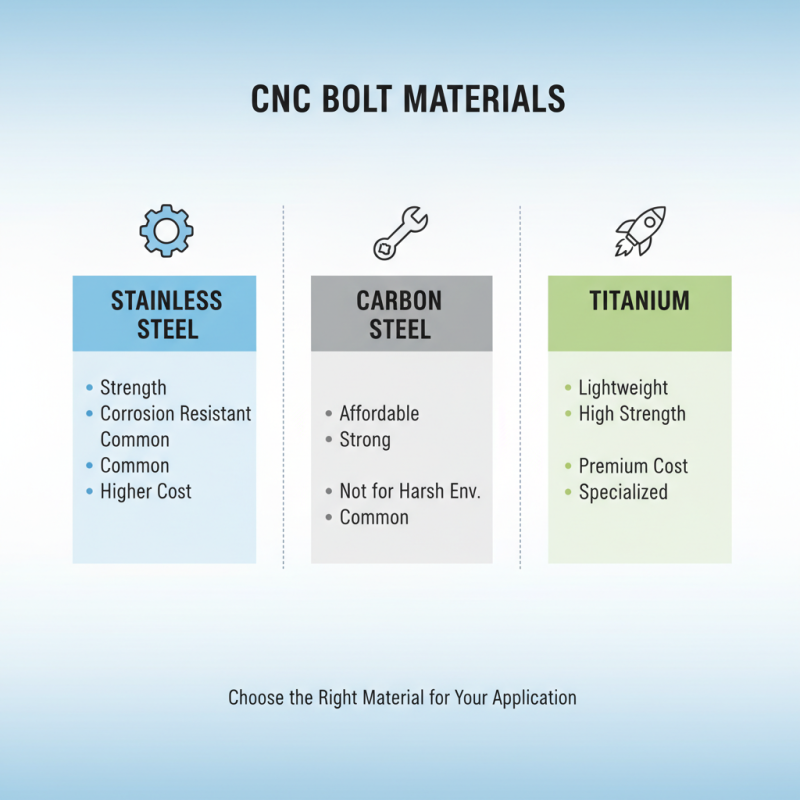

When choosing CNC bolts, it's essential to consider the material. Stainless steel is common due to its strength and corrosion resistance. However, it can be more expensive. Carbon steel is often a more affordable choice but may not withstand harsh environments. Titanium bolts offer additional benefits like lightweight and high strength, but they come at a premium.

Next, the bolt's size and thread pitch matters greatly. A miscalculation here can lead to installation issues. Always verify dimensions before purchase. Additionally, the coating on the bolts can affect performance. Some coatings enhance durability, while others might not hold up under certain conditions.

Don’t overlook the manufacturer’s specifications. It’s often tempting to disregard them for convenience. This can lead to mistakes later. Proper torque settings should be paid attention to as well. Incorrect torque can weaken the bolt or damage machinery. Make sure to consult industry standards to avoid pitfalls in your projects.

When it comes to CNC bolts, understanding their variations is key. These fasteners come in diverse materials, sizes, and thread types. Each choice affects the performance and durability of your project. Common materials include steel and aluminum, but plastic options exist too. Selecting the right bolt requires careful consideration of the specific application.

The design of CNC bolts can vary significantly. Some have a standard hex head, while others feature specialized shapes. The quality of threading also impacts functionality. For instance, finer threads may provide greater strength but can complicate assembly. It’s also essential to consider the environmental factors that could affect the bolts. Corrosion resistance becomes critical in certain situations.

Many users overlook the importance of precise measurements. A bolt that looks good may not fit properly. This can lead to wasted time and resources. Additionally, the torque specifications must be followed to avoid stripping. Understanding these details adds depth to your projects. Regularly revisiting these aspects can help you refine your process.

| Bolt Type | Material | Diameter (mm) | Length (mm) | Strength Class | Price ($) |

|---|---|---|---|---|---|

| Hex Bolt | Steel | 10 | 50 | 8.8 | 0.10 |

| Carriage Bolt | Stainless Steel | 12 | 60 | A2 | 0.15 |

| Flange Bolt | Alloy Steel | 16 | 75 | 10.9 | 0.20 |

| Set Screw | Carbon Steel | 8 | 30 | 12.9 | 0.05 |

| Wing Bolt | Brass | 5 | 25 | N/A | 0.12 |

| Socket Head Bolt | Stainless Steel | 10 | 40 | 8.8 | 0.25 |

| Lag Bolt | Steel | 14 | 90 | N/A | 0.30 |

| Shoulder Bolt | Alloy Steel | 18 | 70 | 10.9 | 0.35 |

| Thumb Screw | Plastic | 6 | 20 | N/A | 0.08 |

| Eye Bolt | Steel | 10 | 50 | 5.8 | 0.40 |

When working on projects involving CNC bolts, proper installation is key. Ensure you have the right tools ready, such as a torque wrench and screwdrivers. Measure the depth of the hole accurately. An incorrect depth can lead to instability. Always clean the surfaces before installation. Dust and debris can compromise the fit.

Pay attention to the alignment of the bolts. Using a guide can help. Misalignment can cause uneven stress distribution. This might lead to failure over time. If the bolts are too tight, they can strip the material. Conversely, if they’re too loose, they can work themselves free. Finding the right balance is crucial.

Lastly, test your installation under real conditions. This might involve running machinery or applying force to the assembled parts. Look for any signs of weakness. Revisiting your installation process can improve future projects. Reflect on what went well and what did not. Mistakes can lead to valuable learning experiences. Always strive for improvement.

Maintaining CNC bolts is essential for their longevity. Regular inspection helps identify wear and damage. Look for signs of rust or corrosion. These issues can compromise performance. Keeping bolts clean is equally important. Dust and debris can hamper their function. A simple wipe with a soft cloth can make a difference.

Lubrication is another key aspect of care. Using appropriate lubricants ensures smooth operation. Apply a small amount to threaded areas. This prevents the bolts from seizing. However, avoid over-lubrication. It can attract dirt and create more problems down the line.

Storing CNC bolts properly is crucial. Keep them in a dry, cool place. Moisture can lead to rust. Consider using sealed containers or bags. Check your inventory regularly. Replace any bolts that show signs of excessive wear. This approach will save you time and money in the long run. Simple maintenance can significantly enhance the lifespan of your CNC bolts.

This chart compares the tensile strength of various materials commonly used for CNC bolts, measured in megapascals (MPa). Stronger materials like titanium and stainless steel provide greater durability, while lighter options such as plastic and aluminum are used for less demanding applications.