- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

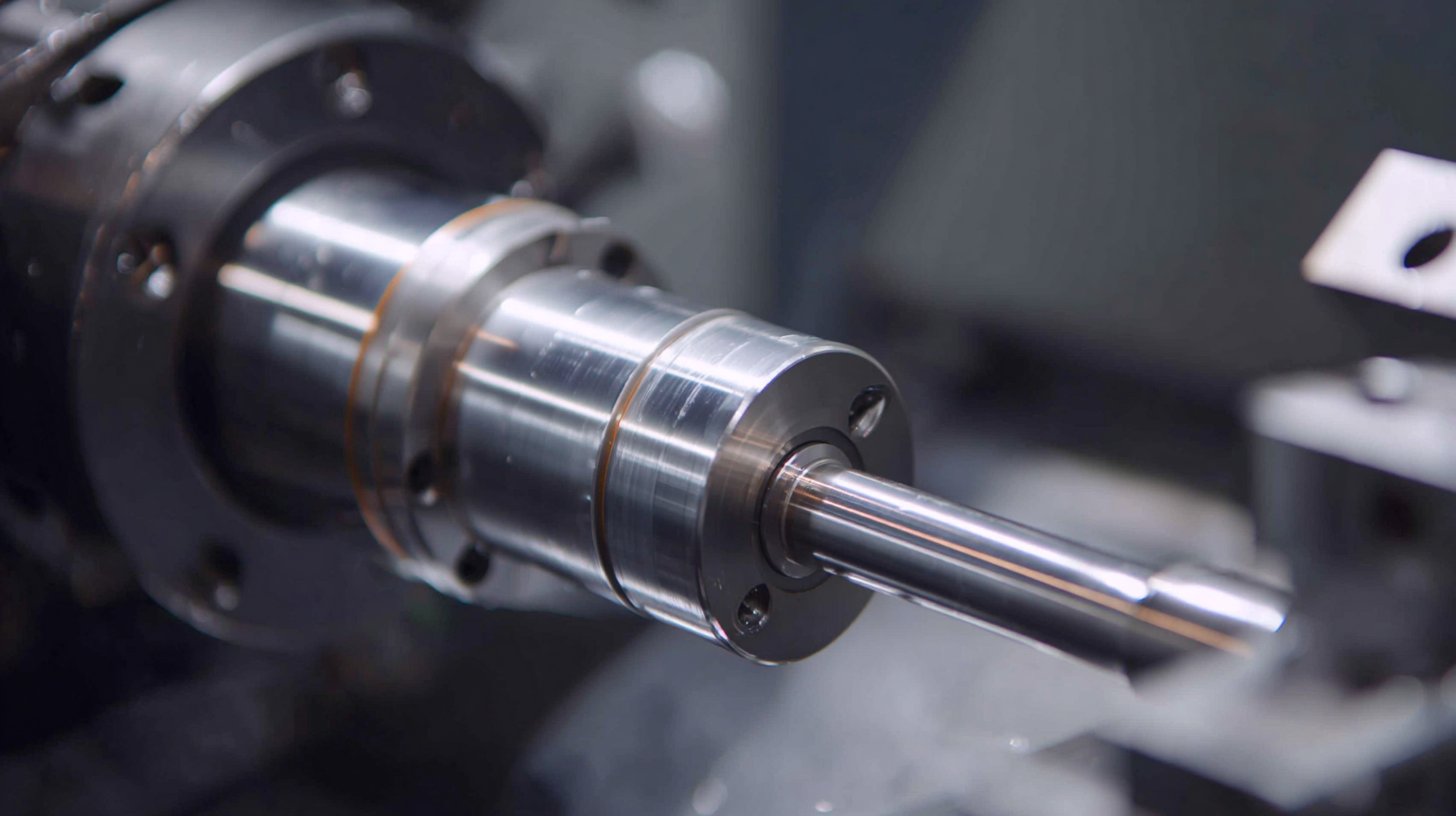

In the ever-evolving world of machining, the choice of components can significantly influence operational efficiency and productivity. One critical component that often goes overlooked is the CNC drawbar. According to a recent report by the International Journal of Advanced Manufacturing Technology, a well-chosen CNC drawbar can enhance machining accuracy by up to 30%, while reducing tool change times by a staggering 50%. This highlights the necessity for manufacturers to make informed decisions when selecting a drawbar that meets their specific requirements.

Understanding the various factors that influence the performance of a CNC drawbar is essential for optimizing machining processes. Factors such as material composition, design specifications, and compatibility with existing machinery directly impact not only the longevity of the drawbar but also the overall effectiveness of the machining operations. A study by the American Society of Mechanical Engineers emphasizes that improper selection of CNC components can lead to increased downtime, operational costs, and subpar output quality, underscoring the importance of careful consideration in the selection process.

In this article, we will outline ten essential tips for choosing the right CNC drawbar tailored to your machining needs. By utilizing these guidelines, manufacturers can ensure they are selecting components that not only enhance productivity but also align with industry best practices, thereby fostering a more efficient and competitive manufacturing environment.

When selecting the right CNC drawbar, the first step is to clearly identify your specific machining requirements. This involves understanding the types of materials you will be working with and the precision level needed for your projects. Different machining tasks demand different drawbar specifications, such as the required clamping force or the compatibility with various toolholders. Taking the time to analyze your machining environment and operational goals can guide you toward the most suitable options.

Additionally, consider the impact of the drawbar’s design on your machining efficiency. Factors such as ease of use, durability, and maintenance are crucial in ensuring that the CNC machine operates smoothly. An optimal drawbar not only enhances tool stability and performance but also minimizes downtime and potential damage to the machine. By closely examining these aspects, you can make an informed decision that aligns with your machining needs and contributes to overall productivity.

When selecting the right CNC drawbar for your machining needs, it’s essential to understand the various types available and their specific applications. CNC drawbars come in several forms, including pneumatic, hydraulic, and manual systems. Pneumatic drawbars are commonly used in high-speed machining environments, as they offer rapid tool changes with minimal downtime. The use of air pressure in these systems allows for swift engagement and disengagement of tools, making them ideal for production settings where efficiency is critical.

On the other hand, hydraulic drawbars are preferred in applications requiring higher clamping forces. They utilize fluid pressure to secure the tool holder, providing significant stability during heavy cutting operations. This makes them suitable for industries such as aerospace and automotive, where precision and reliability are paramount. Manual drawbars, while less common in automated settings, remain popular in smaller shops or for specific applications where operator control is necessary. Understanding these differences will help you choose a CNC drawbar that aligns with your machining requirements, ensuring optimal performance and tool longevity.

| Tip | Description | Application | Advantages |

|---|---|---|---|

| 1 | Identify the type of machining operation | Milling, Turning, etc. | Ensure compatibility with CNC machine |

| 2 | Check the drawbar size | Requires specific dimensions | Improves precision in tool holding |

| 3 | Material selection | Steel, Aluminum, etc. | Durability and stability considerations |

| 4 | Assess the holding force required | High force machining applications | Optimizes tooling performance |

| 5 | Consider maintenance requirements | Routine checks and replacements | Extends tool life and performance |

| 6 | Evaluate compatibility with tools | Tool shank sizes and geometries | Enhances machining efficiency |

| 7 | Choose between manual and automatic | Different operational needs | Improves workflow and productivity |

| 8 | Research manufacturer specifications | Performance and design features | Ensures reliability and quality |

| 9 | Review user feedback | User experiences and reviews | Informs decision-making process |

| 10 | Consult with experts | Professional advice on selection | Maximizes machining potential |

When selecting the right CNC drawbar for your machining needs, understanding key factors such as

material, size, and compatibility is crucial.

The material of the drawbar directly impacts its durability and performance. For instance, materials that

offer high tensile strength and resistance to wear

can significantly enhance machine longevity and reduce the frequency of replacements. In the aerospace sector,

where precision is paramount, opting for high-performance materials that withstand extreme conditions can

lead to more efficient operations.

Size is another important aspect. An appropriately sized drawbar ensures optimal clamping force and

stability during machining processes. If the size is not compatible with the machine's spindle, it could

lead to issues such as misalignment, unacceptable tolerances, and compromised safety. Moreover,

compatibility with existing tooling and fixtures cannot be overlooked. Drawbars designed for specific

CNC machines or types of machining operations will yield the best results, as they are engineered to match

the spindle's requirements seamlessly. This attention to detail will ultimately enhance productivity and

quality in machining tasks.

When selecting a CNC drawbar, evaluating vendor reputation and customer support is crucial to ensure you're making a sound investment. A reputable vendor typically has a track record of quality products and positive customer experiences. Look for companies with industry certifications and a history of reliability. Customer reviews and testimonials can offer insights into the vendor's reliability and product satisfaction. Engaging with industry forums or networking with peers can further illuminate the reputation of potential vendors.

In addition to reputation, the level of customer support offered can significantly impact your decision. A responsive support team can be invaluable, especially when technical issues arise or during the installation process. It's essential to inquire about the vendor's warranty policies and the availability of spare parts and service support. A vendor that provides comprehensive support not only helps in resolving problems efficiently but also assures you that they stand behind their products. By prioritizing vendor reputation and customer support, you can make a more informed choice that caters to your machining needs effectively.

When evaluating the costs associated with CNC drawbars, businesses must weigh their investment against the quality of the product. Recent industry reports indicate that high-quality CNC drawbars can significantly enhance machining efficiency, leading to cost savings in the long run. For instance, investing in premium drawbars may range from 20% to 50% more than standard options, but the durability and reliability of these tools often justify the higher price. A well-chosen drawbar can minimize downtime and maintenance, which are critical factors in maintaining profitability within manufacturing operations.

When evaluating the costs associated with CNC drawbars, businesses must weigh their investment against the quality of the product. Recent industry reports indicate that high-quality CNC drawbars can significantly enhance machining efficiency, leading to cost savings in the long run. For instance, investing in premium drawbars may range from 20% to 50% more than standard options, but the durability and reliability of these tools often justify the higher price. A well-chosen drawbar can minimize downtime and maintenance, which are critical factors in maintaining profitability within manufacturing operations.

When selecting a CNC drawbar, consider these essential tips: First, assess your specific machining requirements. Different materials and designs may necessitate a better-performing drawbar to achieve optimal results. Secondly, do not underestimate the importance of compatibility with your existing machinery. A mismatch can lead to increased operational costs and inefficiencies. Finally, evaluate supplier reputation and support services, as these aspects can influence long-term satisfaction with your investment. Balancing cost and quality is crucial, and thorough research will guide you towards making an informed decision that aligns with your machining needs.