- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the rapidly evolving manufacturing landscape, the selection of the right equipment is crucial for achieving optimal results. When it comes to custom machining tasks, choosing the best Bellows CNC machinery can significantly impact the quality and efficiency of production. According to a recent market report by Research and Markets, the CNC machinery industry is expected to grow by 7.5% annually, underscoring the rising demand for precision engineering tools, including Bellows CNC systems.

Expert insights emphasize the importance of careful consideration when making this choice. Dr. Harold Jenkins, a leading figure in the CNC machining field, notes, "The right Bellows CNC can not only streamline your processes but also enhance the precision of your projects. It's vital for professionals to evaluate their specific needs before making an investment." This highlights the necessity of understanding project requirements and the specific features that various Bellows CNC options provide.

In this article, we'll explore essential tips for selecting the best Bellows CNC for your project needs, helping you to navigate the various options and make an informed decision that aligns with your operational goals. Through a combination of expert advice and market data, we aim to equip you with the knowledge to enhance your machining capabilities effectively.

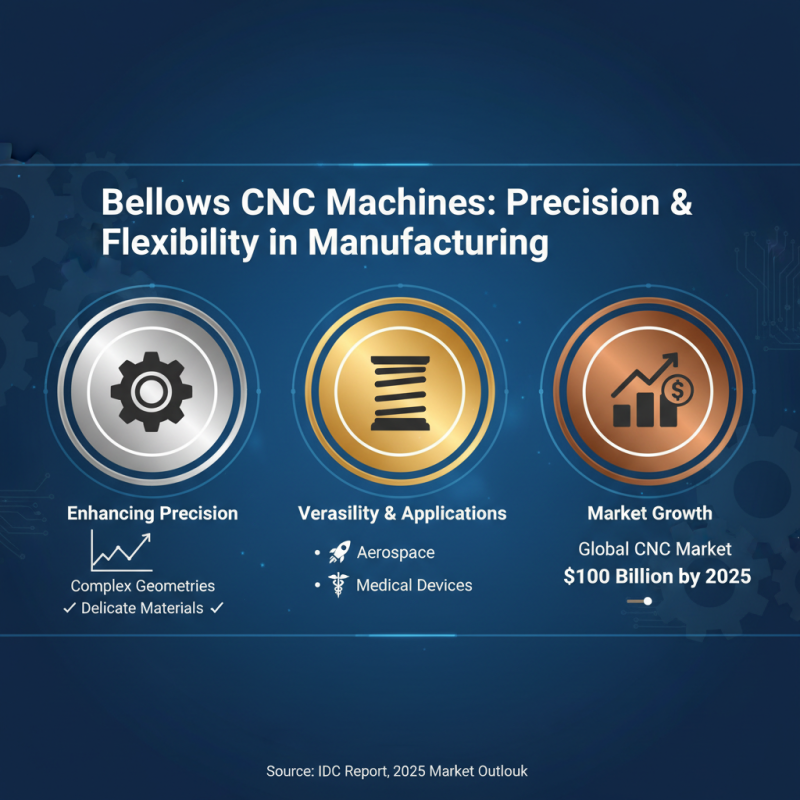

When it comes to CNC machining, bellows CNC machines play a crucial role in enhancing precision and flexibility in various manufacturing processes. These specialized machines are designed to handle complex geometries and delicate materials, making them a popular choice in industries ranging from aerospace to medical device fabrication. According to a report by the International Data Corporation (IDC), the global CNC machine market is anticipated to reach $100 billion by 2025, indicating a robust demand for advanced tooling solutions, including bellows CNC configurations.

Understanding the fundamentals of bellows CNC machines is essential for making informed choices for your projects. These machines are characterized by their ability to manipulate flexible bellow structures, allowing for accommodating movement and thermal expansion. The incorporation of advanced sensors and feedback mechanisms ensures precision during operations. In a survey conducted by the Manufacturing Institute, 70% of manufacturers reported that investing in sophisticated CNC technology improved their production efficiency and reduced waste by up to 30%. This highlights the potential benefits of leverages like bellows CNC machines in optimizing project outcomes.

When selecting a bellows CNC machine, it’s imperative to consider factors such as the machine's compatibility with specific materials, its flexibility in design, and its potential for integration into existing systems. Further research from the American National Standards Institute (ANSI) confirms that machines optimized for versatility demonstrate a higher return on investment through sustained operational efficiency and adaptability to diverse applications, underscoring the importance of making well-informed choices in this technology-driven landscape.

When selecting a bellows CNC for your project, it’s essential to focus on several key factors that will influence performance and efficiency. First and foremost, consider the machine's build quality and stability, as these features directly affect the accuracy and durability of your machining processes. A robust frame helps minimize vibrations, ensuring consistent results, especially when working with challenging materials.

Another crucial aspect is the machine's ease of use and programming capabilities. A user-friendly interface can significantly reduce the learning curve, allowing operators to focus on their work rather than troubleshooting complex controls. Additionally, compatibility with various software packages can enhance flexibility and ease of integration into your existing workflow.

Tips for making the best choice include evaluating the specific needs of your project—whether precision or production speed is a priority—and seeking out feedback from other users about their experiences with different models. Performing hands-on demonstrations can also provide invaluable insights into how well the machine performs in real-world scenarios. By carefully assessing these factors, you can ensure that your bellows CNC aligns perfectly with your project requirements.

This chart displays the key factors to consider when selecting a Bellows CNC machine based on expert evaluations. The factors include precision, cost, maintenance ease, material compatibility, and customer support.

When embarking on a new CNC project, understanding your specific requirements and specifications is crucial for selecting the best bellows CNC system. Begin by assessing the materials you’ll be working with. Different materials have different machining needs, and understanding these will influence your choice of CNC system. Whether you’re dealing with metals, plastics, or composites, ensure that the CNC machine you choose is compatible with the material properties to achieve the desired results.

Tips for Selecting a Bellows CNC: Consider the precision and tolerances required for your project. High-precision tasks demand CNC systems that can operate with tight tolerances, while less rigorous projects may not require such exact specifications. Additionally, evaluate the size of your workpieces and the machine's capability to accommodate them effectively. Choosing a bellows CNC with adjustable features can provide better flexibility for various project sizes.

Another critical factor is your project's speed and efficiency requirements. If your project timeline is tight, look for CNC systems with faster processing capabilities. However, remember that speed should not come at the expense of quality. Find a balance that meets your production pace while maintaining the project standards you aspire to achieve.

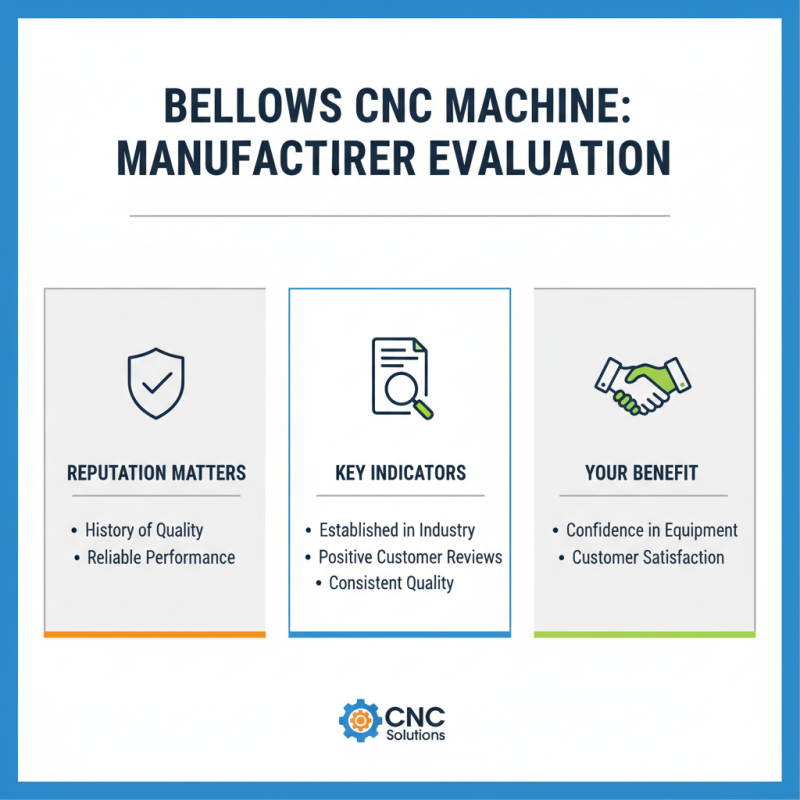

When selecting a bellows CNC for your project, evaluating the manufacturer's reputation is crucial. A well-established manufacturer with a strong history of providing quality products can give you confidence in their equipment's reliability and performance. Look for manufacturers that have been in the industry for a significant period and have positive reviews from previous customers. This can indicate a consistent level of quality in their CNC machines and their commitment to customer satisfaction.

In addition to reputation, effective service support plays a pivotal role in your decision-making process. A manufacturer that offers comprehensive service support can significantly reduce downtime in your operations and ensure smooth project execution. Consider whether they provide adequate training, technical assistance, and easy access to spare parts. Reliable service support can make a difference, particularly when you encounter unexpected challenges or technical issues. Prioritizing these factors will help you choose a bellows CNC that best fits your project needs while ensuring ongoing support from the manufacturer.

When considering the investment in a bellows CNC machine, budgeting plays a critical role in ensuring that you get the best value for your project needs. It is essential to first determine the scope of your projects and the required specifications for the CNC machine. By understanding the functionalities you need, such as precision, speed, and materials to be handled, you can set a realistic budget that matches your operational goals.

To effectively budget for your bellows CNC machine, it is advisable to not only factor in the purchase price but also the long-term operational costs. This includes maintenance, potential upgrades, tooling, and other related expenses. A well-planned budget should accommodate these ongoing costs, ensuring that the initial investment does not become a financial burden over time. Additionally, seeking consultations from industry experts or conducting market research can provide insights into average costs, allowing for a more accurate financial plan.

| Criteria | Description | Estimated Cost ($) | Recommended Features |

|---|---|---|---|

| Size | Consider the size of the workspace and the material to be processed. | 5,000 - 50,000 | CNC machine should fit within your spaced area. |

| Power | The power capacity required to handle your projects. | 10,000 - 60,000 | Look for high torque for better performance. |

| Material Compatibility | Types of materials the CNC can process. | Varies widely | Ensure it can handle the materials you need. |

| Maintenance | Ease of maintenance and support availability. | 1,000 - 5,000/year | Consider machines with good customer service. |

| Software Integration | Compatibility with design and CAM software. | 500 - 3,000 | Ease of use, learning curve, and updates. |