- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

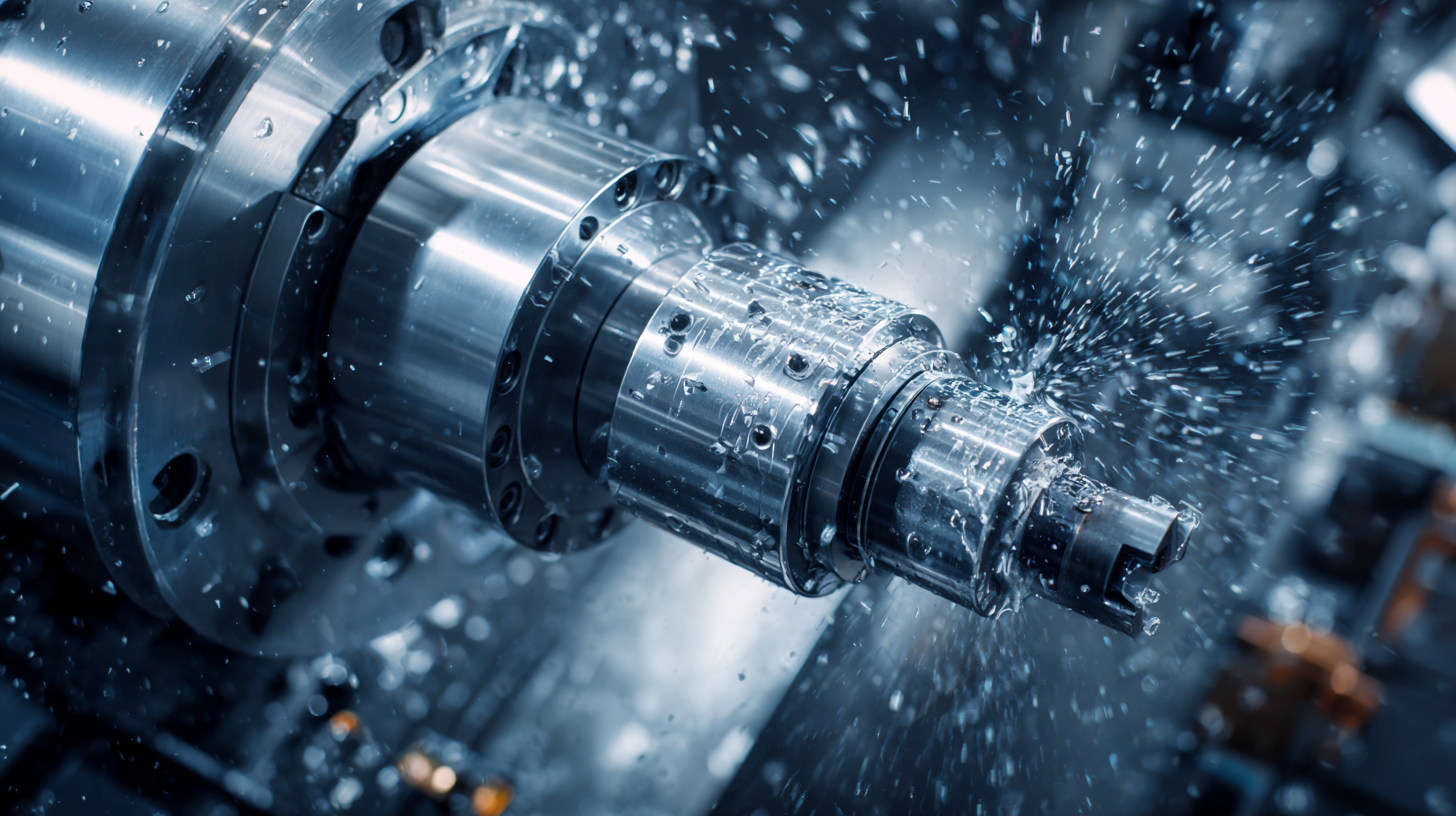

In the rapidly evolving landscape of precision manufacturing, Metal CNC technology has emerged as a cornerstone of innovation, driving efficiency and accuracy in the production process. This exploration of the latest innovations in Metal CNC delves into the transformative capabilities that digital advancements bring to traditional machining techniques. As industries demand higher precision and reduced turnaround times, the integration of cutting-edge software and automation into Metal CNC operations not only streamlines production but also enhances the customization of components to meet specific customer requirements. This introduction sets the stage for a comprehensive examination of how these innovations are sculpting the future of manufacturing, providing insights into the tools and techniques that define the best practices in the field. As we navigate through these developments, we will uncover the pivotal role Metal CNC plays in shaping the industry's trajectory towards greater technological sophistication and productivity.

CNC technology has transformed metal manufacturing by enabling precise control over machining processes through NC-code. This essential programming language dictates how CNC machines move and operate. Understanding its fundamentals allows operators to optimize workflows and reduce production time. The growing incorporation of CNC machines in various industries signifies their critical role in achieving high precision and efficiency in metal fabrication.

**Tips**: Familiarize yourself with the basics of NC-code by engaging in hands-on workshops or online tutorials. Developing a strong foundation in these programming skills will enhance your ability to troubleshoot and innovate on the shop floor.

In addition to traditional machining practices, the integration of additive manufacturing techniques is gaining traction among metal fabricators. Leveraging the strengths of both CNC machining and additive methods creates new opportunities for design flexibility and material efficiency. As manufacturers adopt these hybrid approaches, they can meet the increasing demand for customized products while maintaining strict quality control.

**Tips**: Stay updated on the latest trends in hybrid manufacturing by participating in industry workshops and networking events. Engaging with fellow professionals can provide valuable insights and practical knowledge to navigate this evolving landscape.

| Innovation | Description | Impact on Precision | Adoption Rate (%) | Future Potential |

|---|---|---|---|---|

| Adaptive Machining | Real-time adjustments to machining parameters based on feedback. | Increases accuracy and reduces errors. | 45 | High |

| 5-Axis Machining | Allows complex geometries to be machined in a single setup. | Enhances design flexibility and precision. | 60 | Very High |

| CNC Automation | Integration of robotics to facilitate unattended machining. | Improves operational efficiency and reduces human error. | 55 | High |

| Advanced Tooling Materials | Development of high-performance materials for better durability. | Increases tool life and part quality. | 50 | Moderate |

| IoT Integration | Connecting machines to the Internet for data collection and analysis. | Enhances monitoring and predictive maintenance. | 40 | High |

The landscape of metal CNC technology is rapidly evolving, with several key innovations driving enhanced precision in manufacturing. The integration of advanced robotics and artificial intelligence is revolutionizing traditional machining processes, allowing for increased automation and reduced human error. These technological advancements are leading to improved productivity across a variety of industries, making CNC machines more versatile and efficient in their operations.

The landscape of metal CNC technology is rapidly evolving, with several key innovations driving enhanced precision in manufacturing. The integration of advanced robotics and artificial intelligence is revolutionizing traditional machining processes, allowing for increased automation and reduced human error. These technological advancements are leading to improved productivity across a variety of industries, making CNC machines more versatile and efficient in their operations.

Moreover, the precision of CNC machining is further enhanced through the development of high-performance metal cutting tools. The global metal cutting tools market is projected to grow significantly, reflecting the increasing demand for precision-engineered components. As industries embrace smart manufacturing practices, the focus on achieving tighter tolerances and superior surface finishes becomes paramount, driving the continuous evolution of CNC machines. The future of metal machining promises to be shaped by these innovations, showcasing a clear trend towards more refined and efficient production capabilities.

Integrating CNC technology into production lines is pivotal for enhancing efficiency and precision in metal manufacturing. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $100.94 billion by 2026, growing at a CAGR of 5.6%. This growth underlines the increasing importance of CNC technology in achieving high-quality output and consistent results in precision manufacturing processes. By adopting advanced CNC machines, manufacturers can automate production, reduce human error, and increase productivity significantly.

To effectively integrate CNC technology, it is essential to establish best practices that align with production goals. Firstly, investing in employee training is critical; a study by the National Institute for Metalworking Skills (NIMS) revealed that well-trained workers can improve production efficiency by up to 30%. Additionally, regular maintenance of CNC machines ensures optimal performance, reducing downtime and extending the machinery's life. Furthermore, leveraging advanced software solutions for real-time monitoring and data analysis can provide insights into production flows, enabling manufacturers to make informed decisions and adjustments, thus optimizing the entire production line.

The evolution of CNC metal machining technology heavily relies on advancements in software capabilities. High-quality software tools have become pivotal in optimizing machining strategies, ultimately leading to improved surface finish and overall product quality. A recent industry report indicates that implementing advanced software solutions can reduce surface roughness significantly by up to 30%, enhancing the aesthetic and functional properties of machined parts. This is particularly evident in the transition towards adaptive machining systems that utilize real-time data to adjust operations dynamically.

When considering CNC machining for metal applications, integrating cutting-edge software not only streamlines processes but also enhances precision. As the tools become more sophisticated, they allow manufacturers to simulate and analyze machining operations before actual production, resulting in a drastic decrease in machining errors and material waste.

**Tips:**

1. Invest in software that supports simulation and real-time monitoring to enhance efficiency.

2. Continuously educate your team on the latest software updates to leverage new features effectively.

3. Collaborate with software developers to customize solutions that cater to specific machining needs, ensuring optimal performance.

The future of metal CNC technology is poised for exciting advancements as industries increasingly embrace precision manufacturing processes. Emerging trends in CNC technology highlight the integration of artificial intelligence and automation, which promise to enhance operational efficiency and reduce lead times. As machines become smarter, manufacturers can expect improved accuracy and adaptability in production, enabling them to meet the diverse demands of modern markets.

Market research indicates that the global CNC metal market is projecting significant growth, fueled by the need for customized manufacturing solutions across various sectors. Innovations in design, such as modular machines and advanced materials, are making it possible for businesses to optimize their production capabilities. Additionally, the rise of Industry 4.0 principles is driving the demand for CNC machines equipped with IoT technology, offering real-time monitoring and data analytics to further refine manufacturing processes. With these trends shaping the landscape of metal machining, the industrial sector can anticipate a transformative future in CNC technology.