- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

The manufacturing industry is constantly evolving, driven by the need for

enhanced efficiency and reduced production costs. As highlighted in a recent

report by the Business Research Company, the global CNC machine tool market size

is projected to reach $88.6 billion by 2025, emphasizing the crucial role of

precision components like CNC inserts in this landscape. However, as manufacturers face challenges such as

rising material costs and the demand for sustainable practices, exploring

innovative alternatives to CNC inserts has become imperative. Research from the International Journal of

Advanced Manufacturing Technology suggests that adopting advanced materials and new cutting technologies can lead to

significant reductions in machining time and tool wear. This blog will delve into a checklist of innovative alternatives

to traditional CNC inserts, aimed at enhancing manufacturing efficiency while addressing the industry's shifting needs and

sustainability goals.

The manufacturing industry is constantly evolving, driven by the need for

enhanced efficiency and reduced production costs. As highlighted in a recent

report by the Business Research Company, the global CNC machine tool market size

is projected to reach $88.6 billion by 2025, emphasizing the crucial role of

precision components like CNC inserts in this landscape. However, as manufacturers face challenges such as

rising material costs and the demand for sustainable practices, exploring

innovative alternatives to CNC inserts has become imperative. Research from the International Journal of

Advanced Manufacturing Technology suggests that adopting advanced materials and new cutting technologies can lead to

significant reductions in machining time and tool wear. This blog will delve into a checklist of innovative alternatives

to traditional CNC inserts, aimed at enhancing manufacturing efficiency while addressing the industry's shifting needs and

sustainability goals.

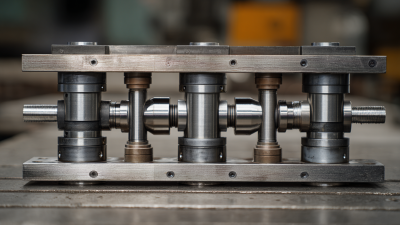

In the ever-evolving landscape of modern manufacturing, the quest for enhanced efficiency has led to a re-evaluation of traditional tools and techniques. Alternative cutting tools have emerged as crucial components in achieving higher productivity levels. These innovative solutions often provide manufacturers with the ability to reduce operational costs while maintaining or even improving the quality of their products.

One significant advantage of employing alternative cutting tools is their ability to address specific machining challenges that conventional CNC inserts may not effectively overcome. For instance, options like ceramic, cermet, and high-speed steel tools can offer superior wear resistance and thermal stability, allowing for faster cutting speeds and extended tool life. This not only minimizes downtime and maintenance costs but also increases the overall output of manufacturing processes.

Moreover, the integration of advanced materials and technologies, such as coated tools and adaptable inserts, has opened new avenues for customization in machining operations. This adaptability is especially vital in industries that require quick transitions between different production runs. As manufacturers continue to prioritize efficiency and precision, the exploration of alternative cutting tools will play a pivotal role in shaping the future of manufacturing processes, driving innovation, and enhancing competitiveness in a global marketplace.

As industries continually seek to enhance manufacturing efficiency, the exploration of innovative alternatives to CNC inserts is critical. The traditional reliance on cemented carbides, which accounted for 53% of cutting tool materials in 2013, has been challenged by emerging materials like CBN (Cubic Boron Nitride), PCBN (Polycrystalline Cubic Boron Nitride), and advanced ceramics. These alternatives offer unique advantages that can significantly improve performance in various machining applications.

CBN and PCBN materials are recognized for their exceptional hardness and thermal stability, making them suitable for high-speed machining of hardened steels, where traditional inserts may struggle. Reports indicate that in sectors where high-performance machining is essential, the adoption of CBN and PCBN has seen considerable growth. Meanwhile, ceramics provide remarkable wear resistance and are effective in dry cutting applications, further diversifying the options available to manufacturers. As we analyze these materials in comparison to conventional options, it becomes clear that leveraging their unique properties will be essential for advancing manufacturing efficiency in a competitive landscape.

CBN and PCBN materials are recognized for their exceptional hardness and thermal stability, making them suitable for high-speed machining of hardened steels, where traditional inserts may struggle. Reports indicate that in sectors where high-performance machining is essential, the adoption of CBN and PCBN has seen considerable growth. Meanwhile, ceramics provide remarkable wear resistance and are effective in dry cutting applications, further diversifying the options available to manufacturers. As we analyze these materials in comparison to conventional options, it becomes clear that leveraging their unique properties will be essential for advancing manufacturing efficiency in a competitive landscape.

The shift from traditional CNC inserts to innovative alternatives is gaining traction due to the significant economic impact this transition can have on manufacturing efficiency. According to recent industry reports, companies that adopt advanced tooling solutions can experience up to a 30% reduction in machining costs while improving product quality and reducing waste. These innovations often incorporate AI and data analytics to optimize cutting processes, leading to enhanced performance and lower operational costs.

Tips: When considering a transition to innovative inserts, manufacturers should conduct a thorough cost-benefit analysis. Evaluate the potential savings from reduced material waste and increased productivity against the upfront investment in new tooling technologies. Another important consideration is the training required for staff to effectively utilize new equipment; investing in training can significantly enhance the return on investment.

As artificial intelligence continues to penetrate various industries, the manufacturing sector stands to benefit from enhanced machining capabilities. By leveraging technology, businesses can not only improve efficiency but also adapt more quickly to market demands, resulting in a more resilient operation. Embracing these innovative solutions is a strategic move towards achieving long-term sustainability and profitability.

The rapid advancements in technology have significantly impacted the CNC machining sector, paving the way for the adoption of non-traditional inserts that enhance manufacturing efficiency. According to a recent industry report by Grand View Research, the global CNC machining market is projected to reach $100 billion by 2025, driven by innovations in tool materials and coatings that increase productivity and reduce downtime. These technological advancements are not only boosting the lifespan of inserts but also improving the precision and speed of machining operations.

Non-traditional inserts, including ceramic and composite materials, are gaining traction due to their superior performance in high-temperature environments and their ability to withstand wear and tear. Research from the Association for Manufacturing Technology indicates that utilizing advanced ceramic tools can enhance machining efficiency by up to 40%, particularly in hard materials that are challenging for conventional inserts. As manufacturers become increasingly focused on optimizing production processes, the shift towards these innovative alternatives is set to transform the landscape of CNC machining, unlocking new possibilities in both quality and cost-effectiveness.

| Alternative Insert Type | Material Composition | Application Area | Efficiency Improvement (%) | Cost Comparison |

|---|---|---|---|---|

| Ceramic Inserts | Alumina, Silicon Carbide | High-speed Steel (HSS) | 30% | Similar |

| CBN Inserts | Cubic Boron Nitride | Hard Metals | 25% | Higher |

| PCD Inserts | Polycrystalline Diamond | Non-ferrous Materials | 40% | Much Higher |

| Bi-metal Inserts | Steel, Titanium | Difficult-to-machine Alloys | 15% | Lower |

| Aluminium Inserts | Aluminium Oxide | Soft Materials | 20% | Lower |

The integration of sustainable alternatives in CNC operations is pivotal for enhancing environmental performance and reducing the overall ecological footprint. Recent studies emphasize the potential of innovative lubrication and cooling techniques, suggesting that approaches like minimum quantity lubrication (MQL) can significantly improve machining efficiencies while minimizing waste and resource consumption. For example, exploring alternative lubrication strategies in broaching medium-carbon steel not only boosts the machining performance but also contributes to lower environmental impacts during the life cycle of manufacturing processes.

Moreover, the adoption of materials such as lignin-based blended resins presents a viable route to diminish reliance on traditional fossil fuels in production practices. As CO2 emissions soar, transitioning toward these renewable, low-carbon options is critical. Industry reports indicate that such shifts can yield substantial benefits, highlighting the importance of a comprehensive life cycle analysis in evaluating production strategies that prioritize sustainability.

**Tips:** Consider implementing MQL techniques in your CNC operations to enhance efficiency and sustainability. Evaluate the materials used in your production processes—opting for renewable resources can significantly lower your carbon footprint. Embrace continuous learning about advanced technologies that promote a circular economy to stay ahead in environmentally conscious manufacturing.