- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

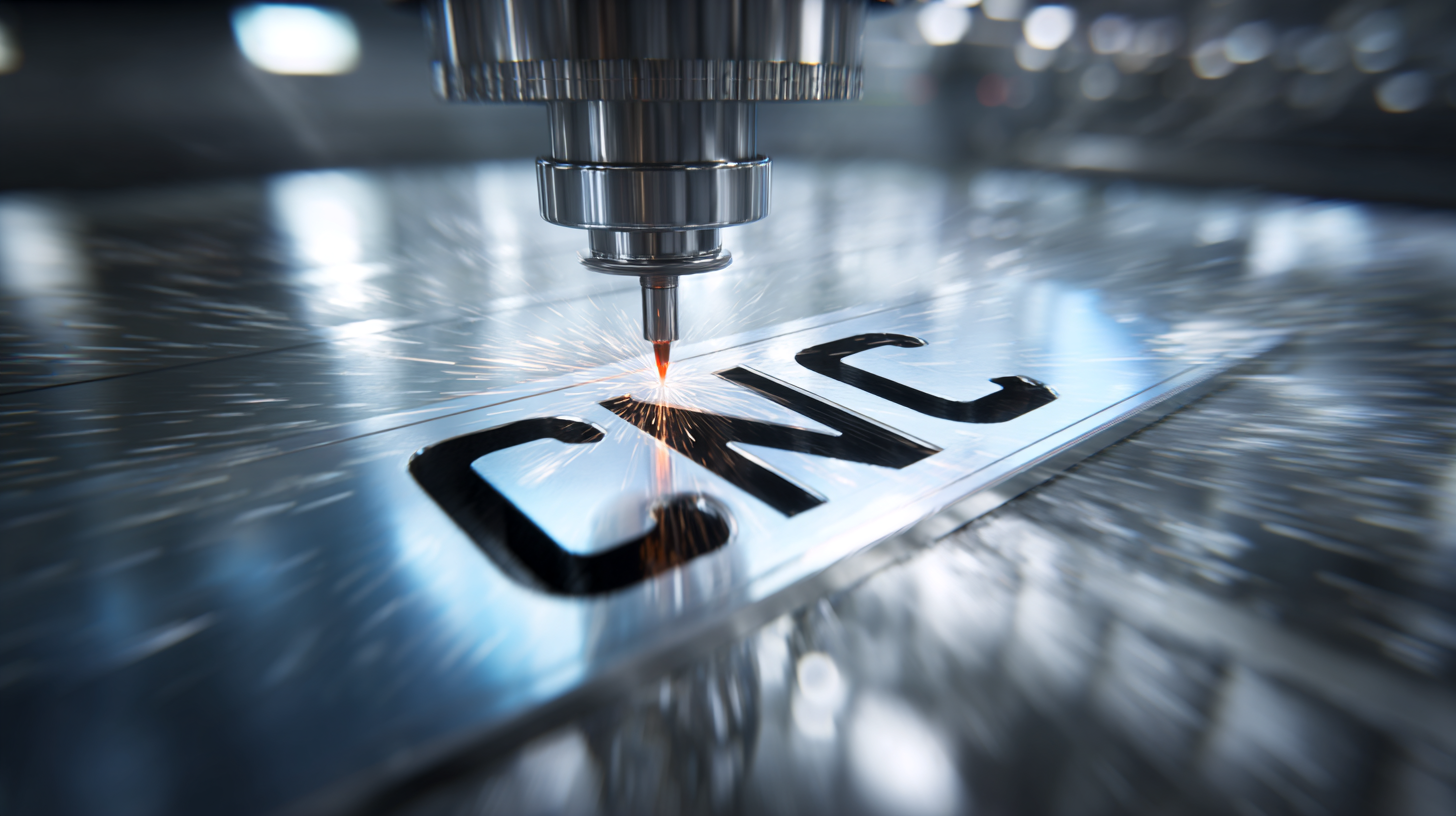

In today's manufacturing landscape, the demand for precision and efficiency has led to the widespread adoption of CNC machines across various industries. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, driven by advancements in automation and the growing demand for high-quality manufacturing processes. These machines, which automate complex cutting and shaping tasks, are no longer confined to traditional sectors such as aerospace and automotive; they are increasingly being utilized in sectors including healthcare, construction, and even art.

As businesses seek alternatives to traditional machining techniques, exploring the real-world applications of the best CNC machines becomes essential for optimizing production and enhancing competitiveness. This in-depth guide will delve into various alternative types of CNC machines, highlighting their unique capabilities and contributions to modern manufacturing.

As businesses seek alternatives to traditional machining techniques, exploring the real-world applications of the best CNC machines becomes essential for optimizing production and enhancing competitiveness. This in-depth guide will delve into various alternative types of CNC machines, highlighting their unique capabilities and contributions to modern manufacturing.

The evolution of CNC machines is a fascinating journey that showcases the innovation and technological advancements in manufacturing. From their initial concept as simple tools for automated cutting, CNC machines have transformed into sophisticated robots capable of executing complex tasks with precision and speed. This evolution has been driven by the integration of advanced technologies such as AI, robotics, and digital transformation, allowing manufacturers to enhance productivity and streamline their operations.

Today, CNC machines are at the forefront of industrial innovation, particularly in regions like China, which is increasingly recognized as a leader in advanced manufacturing capabilities. The machine tool industry here is not only thriving but also adapting to new market trends and opportunities, offering a fertile ground for foreign investment and collaboration. As we look towards the future, the rapid advancements in laser cutting technology and the emergence of smart manufacturing practices signal a new era for CNC applications, promising more efficient, cost-effective, and flexible production methods that meet the demands of a dynamic marketplace.

CNC machines have become essential tools across various industries, significantly contributing to manufacturing efficiency and precision. The key features of the best CNC machines vary depending on the specific applications they serve. For instance, industries such as automotive and aerospace leverage high-speed machining capabilities to achieve intricate designs and tight tolerances, essential for their complex parts. Features like multi-axis capabilities enable these machines to perform sophisticated operations that traditional machines cannot, streamlining production processes and enhancing output quality.

In sectors like furniture manufacturing and medical device production, CNC machines equipped with advanced software and automation capabilities offer flexibility and adaptability. The integration of smart technology allows real-time monitoring and adjustments, resulting in reduced downtime and waste. Moreover, the versatility of CNC machines allows them to work with an array of materials, from metals to plastics and wood, catering to different industrial needs. As industries continue to evolve, the demand for advanced CNC machines is expected to grow, reflecting the significant market potential in the coming years.

| Industry | Key Features | Typical Applications | Material Compatibility | Precision Level |

|---|---|---|---|---|

| Aerospace | High-speed spindle, multi-axis control | Parts manufacturing, prototyping | Aluminum, titanium, composite materials | 0.001 mm |

| Automotive | Robust tooling, fast setup | Engine components, custom parts | Steel, plastic, aluminum | 0.005 mm |

| Medical | CNC milling, high precision | Surgical instruments, implants | Titanium, stainless steel | 0.001 mm |

| Woodworking | Easy to operate, customizable | Furniture making, carvings | Wood, MDF, plywood | 0.1 mm |

| Electronics | Precision routing, laser engraving | PCBs, component housings | Copper, aluminum, plastic | 0.01 mm |

In the realm of advanced manufacturing, CNC (Computer Numerical Control) technology has paved the way for numerous success stories across various industries. One notable case study involves a small aerospace components manufacturer that adopted CNC machining to enhance precision and reduce waste. By transitioning from traditional methods to CNC technology, they significantly improved their production efficiency, slashing lead times from weeks to just days. This shift not only resulted in cost savings but also positioned them as a competitive player in a high-demand market.

Another compelling example can be found in the fashion industry, where a bespoke clothing manufacturer utilized CNC laser cutting to revolutionize their design processes. By integrating CNC machines, they were able to create intricate patterns and designs that would have been nearly impossible with manual cutting. This innovation not only allowed for greater design flexibility but also enabled faster turnaround times for custom orders. As a result, the company not only increased customer satisfaction but also expanded its client base, illustrating how embracing CNC technology can lead to transformative outcomes in diverse sectors.

When selecting the best CNC machine for your business needs, it’s essential to conduct a comprehensive comparative analysis that takes into account the varied applications, types, and market trends influencing the industry. The CNC machine market is witnessing significant growth, particularly in metal cutting and forming segments, with a projected compound annual growth rate (CAGR) of 4.2% through 2030. Businesses must assess their operational requirements, such as material types and production volumes, to determine which CNC machine type aligns best with their goals.

For companies entering or expanding in the manufacturing space, understanding the CNC metal cutting and forming distinctions is crucial. Metal cutting machines are particularly beneficial for precision tasks required in industries such as aerospace and automotive, while metal forming machines cater to applications where material shaping is essential. By evaluating these factors, businesses can make informed decisions that not only optimize production efficiency but also enhance overall product quality, positioning them competitively in the marketplace.

As industrialization continues to surge, the right CNC machine can unlock numerous opportunities for innovation and growth.

The field of CNC machining is on the cusp of significant transformation, driven by emerging technologies and changing consumer preferences. According to a recent report by a leading industry analyst, the global CNC machine market is projected to reach a value of over $100 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.5% from 2022. This growth is fueled by the increasing demand for precision, efficiency, and automation across various sectors, including aerospace, automotive, and medical devices.

Innovative trends such as cloud-based CNC solutions and AI-driven machine learning are paving the way for smarter, more adaptable machining processes. These advancements enable manufacturers to optimize production efficiency and minimize waste, aligning with sustainability goals. A 2023 study indicated that over 60% of manufacturers have already integrated some form of smart technology into their CNC operations, resulting in significant cost savings and improved output quality.

Moreover, the growing emphasis on customization is reshaping the CNC landscape. As industries endeavor to meet rising consumer expectations for bespoke products, CNC technology now supports intricate design requirements with unparalleled accuracy. The confluence of creativity and technology is setting a new standard in manufacturing, opening avenues for innovative applications that resonate with contemporary consumer desires. In this dynamically evolving scenario, staying abreast of these trends will be crucial for stakeholders aiming to maintain a competitive edge.

This chart illustrates the projected growth and adoption rates of various innovations in the CNC machining industry over the next five years. The trends indicate a significant shift towards automation and smart manufacturing technologies.