- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In recent years, CNC turning has emerged as a critical component in the landscape of modern manufacturing, redefining precision engineering across various industries. According to a report by Grand View Research, the global CNC machining market is expected to reach $100 billion by 2025, highlighting the growing demand for efficient and precise manufacturing solutions.

CNC turning, characterized by its ability to produce intricate components with superior accuracy and repeatability, has catalyzed advancements in sectors such as aerospace, automotive, and medical device manufacturing. As manufacturers seek to enhance productivity while reducing waste, understanding the intricacies of CNC turning techniques is essential.

This guide will delve into the foundational elements of CNC turning, exploring how it not only meets the needs of contemporary production but also sets the stage for future innovations in manufacturing technology.

CNC turning, characterized by its ability to produce intricate components with superior accuracy and repeatability, has catalyzed advancements in sectors such as aerospace, automotive, and medical device manufacturing. As manufacturers seek to enhance productivity while reducing waste, understanding the intricacies of CNC turning techniques is essential.

This guide will delve into the foundational elements of CNC turning, exploring how it not only meets the needs of contemporary production but also sets the stage for future innovations in manufacturing technology.

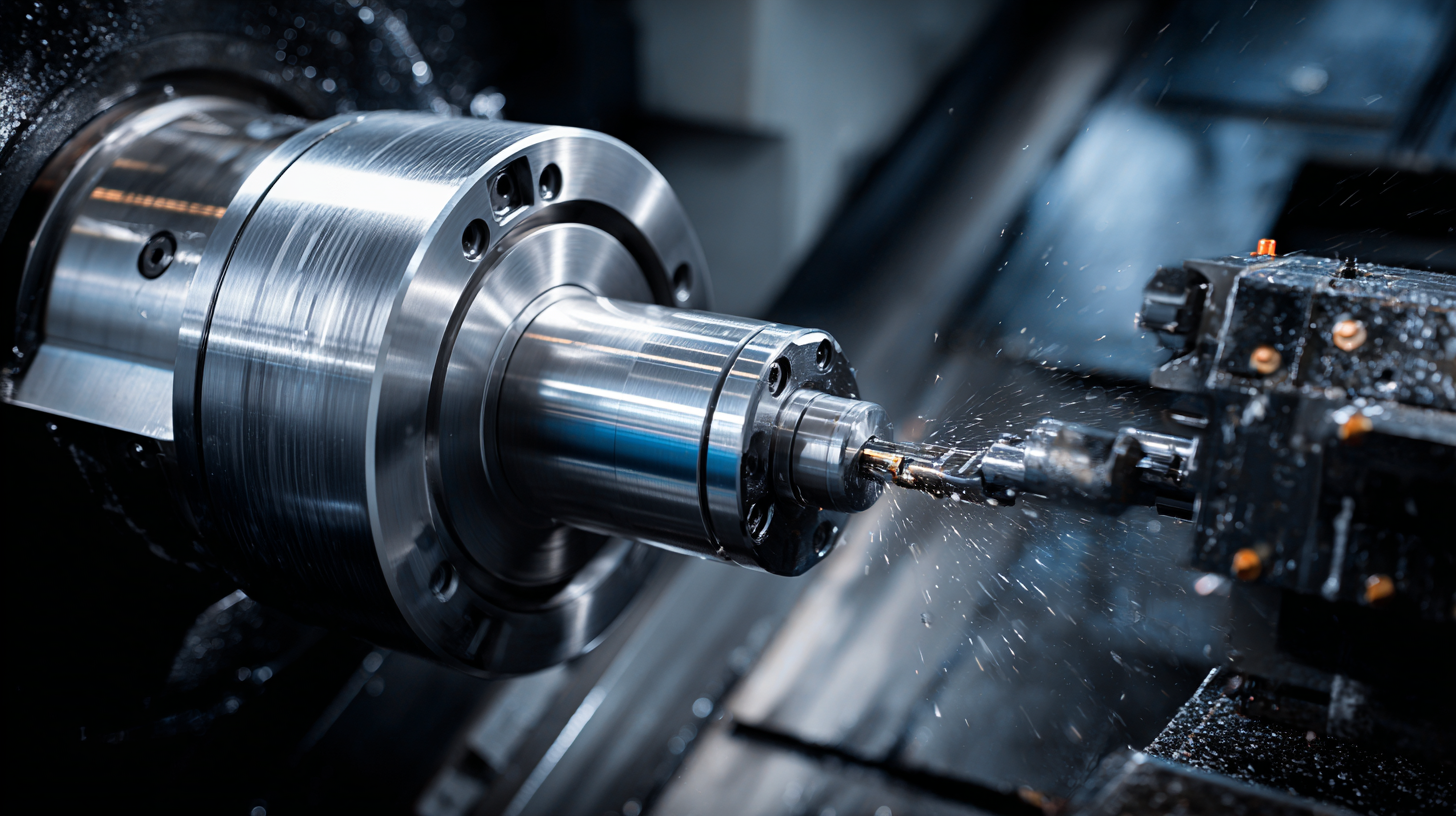

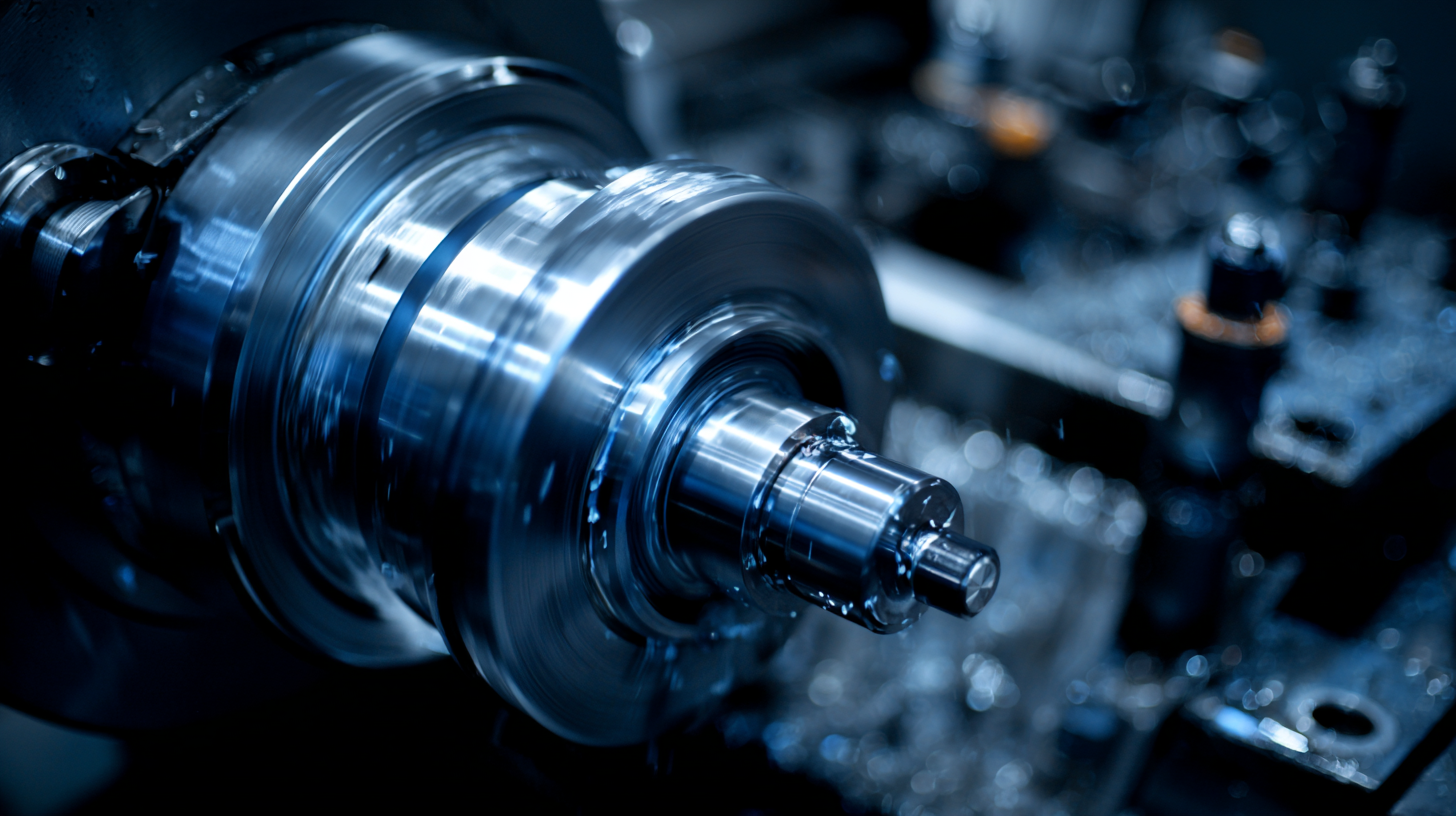

CNC turning is a fundamental manufacturing technique that utilizes computer numerical control to create precise cylindrical parts. At its core, CNC turning transforms raw materials into functional components by rotating the workpiece against a stationary cutting tool. This process is guided by CNC programming, which dictates the tool path, speed, and depth of cut, ensuring high accuracy and repeatability. Understanding key terminology, such as feed rate, spindle speed, and tool geometry, is crucial for anyone looking to master CNC turning techniques.

Tip: For beginners in CNC turning, start by familiarizing yourself with the software used for programming. Exploring simulation features can help you visualize the machining process before hitting the operation button, minimizing the risk of errors.

Another critical aspect of CNC turning is tooling. Different materials require specific tooling choices to achieve optimal results. High-speed steel (HSS) and carbide tools are commonly used depending on the workpiece material. Additionally, keeping your tools sharp and well-maintained significantly enhances the quality of the finished product.

Tip: Regularly inspect your tools for signs of wear or damage and replace them as necessary. A well-maintained tool not only improves efficiency but also extends the overall lifespan of your CNC machine.

CNC turning has become an integral technique in modern manufacturing, particularly as industries adapt to the rapid advancements of Industry 4.0. This shift is characterized by the integration of AI, IIoT, and robotics, which significantly enhance operational efficiency and precision. According to recent reports, companies that leverage AI-driven predictive maintenance tools have experienced a notable reduction in equipment downtime, with studies indicating potential cost savings of up to 30% in maintenance costs alone. This alignment with modern technologies not only streamlines manufacturing processes but also facilitates real-time decision-making, empowering manufacturers to remain competitive.

Furthermore, the emergence of generative AI is reshaping traditional manufacturing landscapes by optimizing design processes and accelerating production timelines. As reported, the automation of automotive manufacturing, for example, is projected to enhance production rates by 20% by 2025, driven by the adoption of collaborative robots and advanced data analytics. Statistics show that regions like the Gulf are increasingly investing in Industry 4.0 technologies, which has contributed significantly to the region's manufacturing growth, thereby illustrating the transformative impact of CNC turning and related technologies in navigating the challenges of contemporary manufacturing environments.

CNC turning is a pivotal process in modern manufacturing, enabling precise shaping of materials through the controlled rotation of a workpiece. The evolution of CNC turning has brought forth techniques ranging from basic methods, such as simple cylindrical turning, to advanced strategies including multi-axis milling and live tooling options. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $117 billion by 2025, highlighting the growing significance of CNC turning within the overall manufacturing landscape.

Basic CNC turning techniques focus on turning operations, which involve machining materials with a single-point cutting tool to create cylindrical parts. However, as industries demand more complex geometries, advanced techniques such as synchronous and asymmetric turning are gaining popularity. Data from the International Federation of Robotics indicates that the adoption of robotic CNC machines could boost production efficiency by up to 30%, showcasing the industry’s shift toward integrating automation into conventional turning practices. This blend of basic and advanced methods not only enhances precision but also optimizes manufacturing processes, making CNC turning an essential component of contemporary production systems.

This bar chart illustrates the proficiency levels in various CNC turning techniques used in modern manufacturing. Each technique is assessed based on its importance and frequency of use among professionals in the industry.

Material selection plays a pivotal role in CNC turning, as it directly influences both the quality of the finished components and the overall efficiency of the production process. According to a recent industry report by the Association for Manufacturing Technology, improper material choice can lead to a staggering 30% increase in machining time due to difficulties in cutting, shaping, and finishing. For instance, using high-strength steels or titanium without the correct tooling can cause excessive wear on tools, which not only affects product quality but also incurs higher costs related to tool replacement.

Tips: Always consult the material specifications and machining parameters before starting a project. Understanding the machinability of materials can help in selecting the right tools, reducing downtime and boosting efficiency.

Additionally, the impact of material selection extends to surface finish and tolerances. A study by the International Journal of Advanced Manufacturing Technology found that selecting appropriate materials can enhance surface finish by up to 25%, which is crucial for components that require precise tolerances. This means manufacturers must weigh material properties carefully against their requirements for durability and aesthetics.

Tips: Implementing a rigorous material evaluation process can prevent production setbacks and ensure that your CNC turning operations meet both quality and performance standards.

The world of CNC turning is rapidly evolving, with future innovations poised to reshape the manufacturing landscape. As technology advances, we are witnessing a significant integration of automation and artificial intelligence, which enhances precision and reduces human error. These innovations not only streamline production processes but also enable manufacturers to respond swiftly to market demands. Predictive maintenance powered by AI algorithms is expected to become a standard practice, reducing downtime and optimizing operational efficiency.

Moreover, the emergence of advanced materials and cutting tools will further define the future of CNC turning. Manufacturers are likely to adopt composite materials and carbide tools that offer improved durability and performance. Additionally, developments in 3D printing technology could lead to hybrid manufacturing environments, where CNC turning and additive manufacturing coexist to create complex geometries that were previously unattainable. As these advancements unfold, the industry will adapt, prioritizing sustainability and evolving skill sets to meet the challenges of a dynamic manufacturing ecosystem.