- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

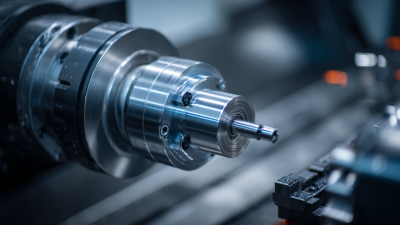

In the world of precision machining, CNC Turning stands as a cornerstone technique that enables manufacturers to produce high-quality components with remarkable accuracy. This advanced machining process utilizes computer numerically controlled (CNC) equipment to turn material against a cutting tool, generating precise shapes and finishes that are critical for various industries, from aerospace to medical devices. With the increasing demand for precision and efficiency in manufacturing, understanding the essential techniques of CNC Turning has never been more vital for engineers and machinists alike.

This article will delve into the top ten essential CNC Turning techniques that can significantly enhance machining quality and operational efficiency. From optimizing toolpaths to selecting the right cutting tools, each technique plays a crucial role in achieving desired outcomes. Whether you are a seasoned professional looking to refine your skills or a newcomer eager to grasp the fundamentals, these insights will provide a comprehensive understanding of the best practices in CNC Turning. As the industry evolves, staying informed about these key techniques ensures that you remain competitive and capable of meeting the rigorous demands of precision machining.

CNC turning is a fundamental machining process used extensively in manufacturing industries for producing precision components. At its core, CNC (Computer Numerical Control) turning involves the rotation of a workpiece against a cutting tool to achieve specific shapes and dimensions. Understanding the essential terminology associated with CNC turning is crucial for professionals in the field. Key concepts include spindle speed, feed rate, and tool path, all of which directly impact the quality and efficiency of the machining process. Reports from industry experts indicate that CNC turning can improve production efficiency by up to 30% when compared to traditional machining methods due to its automated capabilities and precision control.

Another critical aspect of CNC turning is the variety of techniques available to enhance precision machining. Techniques such as constant surface speed and adaptive tool control help optimize the machining process, reducing cycle times while maintaining the integrity of the workpiece. According to the latest market analysis, the demand for precision components has surged, with CNC turning technology projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2022 to 2027. This growth underscores the importance of mastering CNC turning concepts and terminology to meet industry standards and customer expectations effectively, as competition intensifies across various sectors. Embracing a comprehensive understanding of these fundamental elements not only fosters innovation but also equips manufacturers to respond adeptly to evolving market needs.

CNC turning is a crucial process in precision machining, enabling the production of complex geometries with high accuracy. Mastering essential CNC turning techniques can significantly improve the quality of your finished products. One fundamental technique is ensuring proper tool setup. A well-aligned tool can drastically reduce wear and tear, leading to better finishes and longer tool life. Additionally, maintaining the right cutting speed and feed rate is vital for optimizing performance and achieving desired tolerances.

Tips: Always refer to the material specifications when setting the cutting parameters. Taking the time to adjust these settings based on the specific characteristics of the material will enhance the overall machining process.

Another key technique involves the use of proper workholding methods. Securely clamping the workpiece minimizes vibrations, which can cause inaccuracies during the machining process. Depending on the part’s geometry, various types of clamps or fixtures may be required. Experimenting with different setups can help you find the most effective solution for your specific applications.

Tips: Regularly check the alignment of your workholding fixtures to ensure consistent results and prevent errors that could compromise the precision of your machining operations.

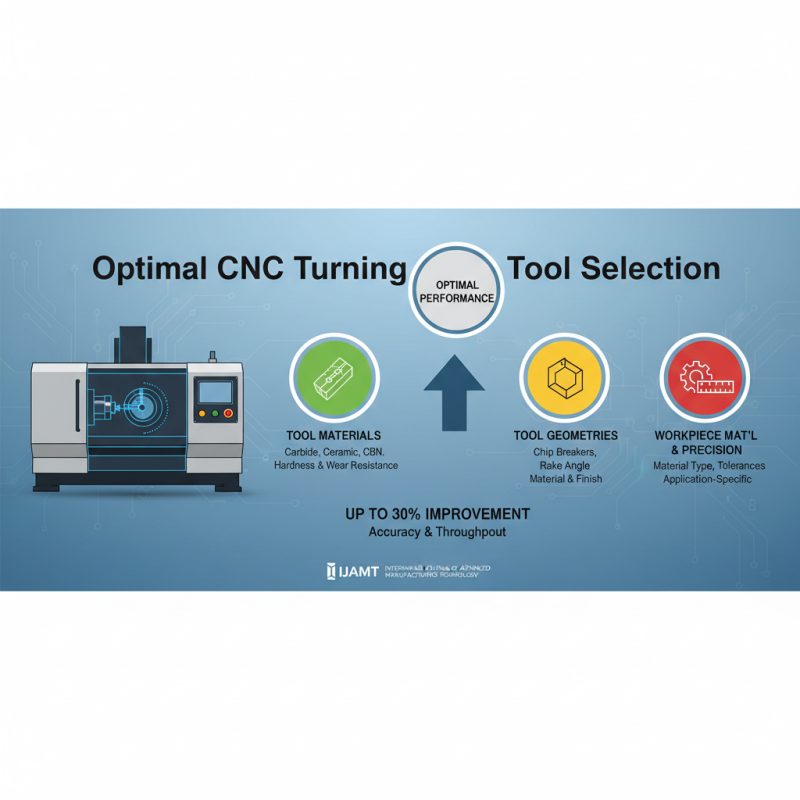

Selecting the right tools for optimal CNC turning operations is crucial for achieving precision and efficiency in machining processes. The effectiveness of CNC turning largely depends on the tooling materials and geometries used, which must be chosen based on the specific requirements of the workpiece material and the desired precision. According to a report by the International Journal of Advanced Manufacturing Technology, tool selection can impact machining accuracy and throughput by as much as 30%.

High-speed steel (HSS) and carbide tools are among the most commonly used types in CNC turning. While HSS tools are often favored for their toughness and ease of sharpening, carbide tools are preferred for high-speed operations due to their hardness and wear resistance. A study published by the American Society of Mechanical Engineers found that using high-quality carbide tools can reduce cycle times by up to 20% while maintaining tight tolerances.

Moreover, the design of the tool holder and insert is essential for minimizing vibration and ensuring stability during the turning process. Advanced tool geometries, such as those with positive rake angles, can significantly enhance chip removal efficiency and surface finish quality. The use of toolpath simulation software helps in optimizing the selection of tooling options, which can lead to system-level improvements in CNC performance and productivity. As the industry continues to evolve, staying updated on the latest tooling technologies and materials is essential for maximizing the potential of CNC turning operations.

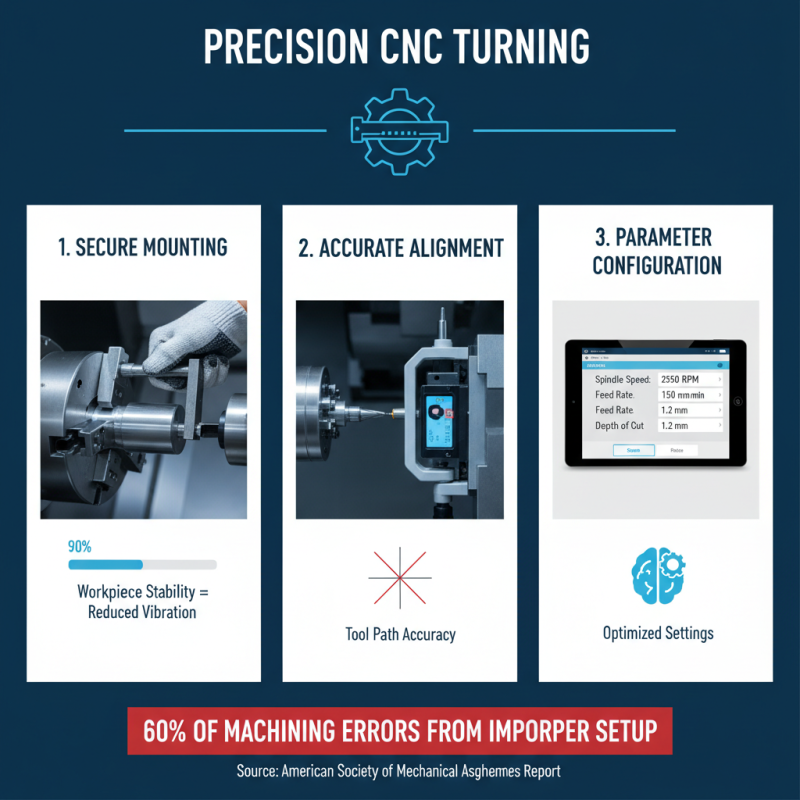

When it comes to CNC turning, achieving precision begins with a meticulous setup and calibration process. According to a report by the American Society of Mechanical Engineers, nearly 60% of machining inaccuracies stem from improper setup. Therefore, it is crucial to ensure that workpieces are securely mounted, tools are accurately aligned, and that the machine's parameters are correctly configured before commencing any operation. This initial stage not only minimizes errors but also enhances the overall efficiency of the machining process.

Calibration plays a pivotal role in maintaining the precision of CNC turning. According to industry experts, regular calibration checks can improve machining accuracy by up to 90%. This involves routinely verifying the machine's geometric accuracy, tool offsets, and spindle alignment. A well-calibrated CNC machine not only prolongs tool life but also reduces material wastage, which is a significant cost saver for manufacturers. Moreover, utilizing advanced measurement technologies, such as laser interferometry or optical encoders, can provide real-time feedback, allowing operators to make necessary adjustments on the fly and ensuring that production standards are consistently met.

CNC turning offers remarkable precision and efficiency in machining processes, yet it comes with its set of challenges. One common issue is tool wear, which can significantly affect the quality and accuracy of the finished parts. According to a 2021 report by the International Journal of Advanced Manufacturing Technology, improper tool selection and dull tools accounted for nearly 45% of production defects in CNC machining. To mitigate this, operators should regularly monitor tool condition and utilize advanced materials such as carbide or ceramic for prolonged tool life.

Another prevalent challenge in CNC turning is the difficulty in managing chip formation and removal. Inadequately managed chips can lead to rework and manufacturing inefficiencies. Data from the Manufacturing Performance Institute indicates that effective chip management can reduce production downtime by up to 30%. A recommended tip for overcoming this challenge is to ensure that the cutting parameters are optimized according to the workpiece material, as this can lead to improved chip flow and minimized clogs.

Additionally, achieving the perfect surface finish can be a hurdle in CNC turning. Surface roughness often hinges on the correct selection of both cutting speed and feed rate. A study by the American Society of Mechanical Engineers highlights that optimizing these parameters can enhance surface quality by up to 50%. Ensuring consistent cooling and lubrication during the cutting process is another crucial factor to maintain precision and avoid thermal deformation, thus preserving dimensional accuracy.