- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the dynamic world of precision machining, Correa CNC machines stand out not just for their advanced technology but also for the comprehensive features that cater to a variety of industrial needs. As Robert King, an expert in CNC machining and automation, once stated, "Investing in the right CNC technology can transform production efficiency and quality, especially when it comes to Correa CNC machines." These machines offer a unique blend of stability, accuracy, and versatility, making them a favored choice among manufacturers across the globe.

Understanding the core features and benefits of Correa CNC machines is crucial for anyone looking to enhance their machining capabilities. From their robust construction to the intelligent software integration, these machines offer solutions that help streamline operations and improve overall productivity. This guide aims to explore the top ten features of Correa CNC machines, detailing how they can provide significant value to your manufacturing processes. Whether you are a seasoned professional or new to the CNC world, recognizing these attributes will empower you to make informed decisions and maximize your investment in Correa CNC technology.

Correa CNC machines are recognized for their advanced capabilities in machining, meticulously engineered to meet a variety of industrial needs.

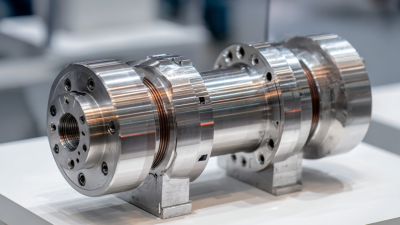

These machines often come equipped with high-performance spindle motors that ensure precision and efficiency while maintaining optimal speeds. Their robust structure is designed to handle heavy-duty cutting tasks, providing stability and durability crucial for achieving high-quality finishes on complex components.

Moreover, modern Correa CNC machines boast an array of user-friendly features, including intuitive control interfaces and advanced programming options. This allows operators to execute intricate machining operations with ease while minimizing setup time. The integration of automation technologies enhances productivity, making these machines suitable for both small-scale workshops and large manufacturing facilities. High adaptability to different materials and machining techniques further solidifies their reputation as versatile tools in the workshop, meeting varied demands from diverse sectors.

When considering the features of Correa CNC machines, there are several key aspects to focus on to ensure you select the right model for your needs. First and foremost is the machine's rigidity and stability. A robust design minimizes vibrations during machining processes, leading to greater precision and improved surface finishes. Look for models that boast a solid construction with heavy-duty components and advanced materials, as these often provide enhanced durability under heavy workloads.

Another critical feature is the control system of the CNC machine. An intuitive and user-friendly interface can significantly streamline operations, making it easier for operators to program complex parts and execute precise movements. Additionally, consider the range of tooling options and the machine's flexibility to accommodate various jobs. This adaptability allows for the handling of different materials and complex geometries, which can be essential for a versatile workshop. Lastly, evaluate the support and maintenance services offered, as this can greatly impact the longevity and performance of your investment.

Correa CNC machines offer numerous benefits that significantly enhance the efficiency and quality of manufacturing processes. One of the most notable advantages is their precision. These machines are designed to execute complex tasks with high accuracy, reducing the margin of error during production. This precision is crucial for industries that require stringent tolerances, as it ensures that components fit together perfectly and meet established specifications. Additionally, the automation capabilities of Correa CNC machines allow for faster production times, enabling manufacturers to meet tight deadlines without compromising on quality.

Another significant benefit is the versatility of Correa CNC machines. They can be programmed to perform a wide range of operations, including milling, drilling, and contouring. This adaptability allows manufacturers to switch between different tasks without needing to invest in multiple specialized machines. Furthermore, their ability to work with various materials, from metals to plastics, makes them suitable for diverse applications across different sectors. By integrating these machines into their operations, manufacturers can streamline processes, reduce labor costs, and ultimately increase their production capacity while maintaining high standards of quality.

When considering the purchase of a CNC machine, especially Correa models, several essential criteria come into play. First and foremost, one must evaluate the machine's precision and accuracy. This is pivotal in ensuring that the finished products meet the required specifications and quality standards. A CNC machine with high-resolution controls and advanced servo systems can significantly enhance output consistency, which is crucial for industries that demand meticulous detail.

Another critical factor is the machine’s versatility and adaptability. A Correa CNC machine should ideally support a range of materials and have the capability to perform various machining operations, from milling to drilling and more. This flexibility allows businesses to diversify their production capabilities without investing in multiple machines. Additionally, ease of programming and integration with existing manufacturing systems can streamline operations, reducing downtime and improving overall efficiency.

Lastly, the availability of support and maintenance services should not be overlooked. A reliable CNC machine must come with robust customer service options, ensuring that any potential issues are promptly addressed. Parts availability and the ease of booking repairs are also significant, as they impact the longevity and uninterrupted operation of the machine. By carefully considering these criteria, buyers can make informed decisions that align with their production needs and budget.

When considering CNC machines, particularly in the context of Correa CNC machines versus other brands, it’s essential to analyze key features and performance metrics that define the competitive landscape. According to a recent industry report by Technavio, the global CNC machine market is expected to grow by 22.89 billion USD from 2020 to 2024, driven by the need for automation and precision in manufacturing. Correa CNC machines are noted for their robust construction, which allows for high precision and durability, often achieving tolerances within ±0.001 mm, making them a preferred choice in heavy-duty machining applications.

In a comparative analysis, it becomes evident that while many CNC brands offer similar basic functionalities, the superior machine rigidity and thermal stability of Correa machines often result in reduced operational downtimes. An internal study by the International Journal of Advanced Manufacturing Technology highlighted that machines with better thermal management can enhance machining accuracy by up to 30%. This feature sets Correa apart, especially in an era where precision and efficiency are paramount. Furthermore, the integration of advanced features such as adaptive control and real-time diagnostics allows for greater flexibility in production settings, making Correa machines a valuable investment in the fluctuating market dynamics of today's manufacturing industry.