- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

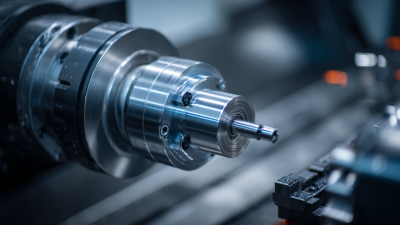

In the ever-evolving field of manufacturing, CNC Turning has emerged as a cornerstone for achieving precision and enhancing efficiency in production processes. According to a recent market analysis by Grand View Research, the global CNC machine market is projected to reach $100 billion by 2025, with CNC Turning playing a significant role in this growth. This technique allows for the meticulous shaping and sizing of materials, crucial for industries ranging from aerospace to automotive.

As expert Jim Anderson, a recognized authority in CNC machining, states, “The future of manufacturing lies in the ability of CNC Turning to produce complex geometries with unparalleled accuracy.” His insights underscore the importance of mastering advanced CNC Turning techniques to improve output quality, reduce waste, and streamline production times. With the advent of smart technologies and automation, optimizing CNC Turning processes has never been more critical for maintaining competitive advantages and meeting rising market demands.

This article will explore the top 10 CNC Turning techniques that can significantly enhance both precision and efficiency, ensuring that manufacturers are well-equipped to navigate the challenges of modern production landscapes. By leveraging these techniques, businesses can optimize their operations, drive innovation, and set new standards in the industry.

CNC turning is a crucial process in precision manufacturing, allowing for the creation of intricate components with exceptional accuracy. By implementing advanced techniques such as peck turning, which optimizes chip removal and minimizes tool wear, manufacturers can enhance both the quality and efficiency of their products. This method not only accelerates production times but also ensures a higher degree of dimensional accuracy, catering to industries that demand tight tolerances.

Another significant technique in CNC turning is the use of multi-axis machines, which enable complex geometries to be machined in a single setup. This reduces the need for multiple setups and minimizes the risk of errors associated with re-aligning parts. Combined with live tooling capabilities, manufacturers can perform drilling and milling operations simultaneously, further increasing throughput and boosting overall productivity. As the industry evolves, these techniques will continue to play a pivotal role in achieving excellence in precision manufacturing.

| Technique | Description | Precision Level | Efficiency Rating |

|---|---|---|---|

| Basic Turning | Standard technique for creating cylindrical parts. | High | Moderate |

| Precision Turning | Optimized for tighter tolerances and details. | Very High | Low |

| Multi-axis Turning | Allows for complex geometries with multiple angles. | High | High |

| Taper Turning | Creates conical shapes by changing diameter along the length. | Medium | Moderate |

| Hard Turning | Machining hardened materials for better surface finish. | High | Low |

| Ceramic Turning | Specialized for machining ceramic materials. | Very High | Very Low |

| Grooving | Creates grooves or indentations along the workpiece. | High | Moderate |

| Parting Off | Used to separate a finished piece from its material. | Medium | High |

| Thread Turning | Creates external or internal threads on a workpiece. | High | Medium |

Live tooling is a revolutionary technique in CNC turning that significantly enhances the capabilities of traditional lathes. By integrating additional rotary and milling functionalities, live tooling allows for the simultaneous machining of multiple sides of a workpiece. This is especially beneficial for complex geometries that require intricate features, such as keyways, slots, and threaded holes, which would typically necessitate multiple setups and increased handling time.

Moreover, the use of live tooling improves precision and efficiency in the machining process. Operators can achieve tighter tolerances and a better finish in a single setup, thus minimizing the risk of errors that can arise from transferring workpieces between machines. Additionally, the reduction in cycle times can lead to increased production rates and cost savings, making it an attractive option for manufacturers aiming to optimize their operations and meet high standards of quality in their outputs.

Optimizing feed rates is a crucial technique in CNC turning that directly influences the efficiency of material removal and the overall precision of machining operations. By adjusting the feed rate, operators can find the sweet spot where material is removed effectively without compromising the tool life or the integrity of the workpiece. Higher feed rates tend to increase productivity, allowing for rapid turnover and reduced cycle times. However, care must be taken to avoid excessive rates that can lead to poor surface finishes or increased wear on cutting tools.

Implementing advanced algorithms and simulation tools can help CNC operators determine the optimal feed rate for specific materials and geometries. This strategic approach to setting feed rates contributes significantly to reducing processing times and improving the quality of the finished product. Additionally, consistent monitoring during machining can allow for real-time adjustments, further enhancing material removal efficiency while minimizing potential issues like tool chatter or vibration. Ultimately, fine-tuning feed rates plays a vital role in maximizing both precision and efficiency in CNC turning processes.

Implementing multiple turning operations significantly enhances efficiency in CNC turning processes. By integrating various operations such as facing, grooving, and boring within a single setup, manufacturers can reduce cycle times and improve throughput. According to a report by the Association for Manufacturing Technology (AMT), optimizing CNC setups through multi-operation techniques can lead to a decrease in production time by up to 30%. This efficiency is pivotal for industries demanding high precision and rapid turnaround, such as aerospace and automotive sectors.

Moreover, utilizing advanced CNC machines that support simultaneous or sequential machining operations allows for greater flexibility and versatility in production. A 2022 survey by Modern Machine Shop indicated that 65% of manufacturers have reduced their lead times significantly by adopting multi-turning operations, resulting in enhanced resource allocation and minimized work-in-progress inventory. With the capability to perform several processes in one setup, shops can not only achieve tighter tolerances but also lower operational costs, ultimately fostering a more competitive edge in the demanding manufacturing landscape.

In modern CNC turning, the choice of tool materials plays a pivotal role in enhancing both precision and efficiency. Advanced tool materials, such as carbide, ceramic, and cermet, provide significant benefits over traditional options. Carbide tools, known for their durability and hardness, are particularly effective in high-speed applications, enabling manufacturers to maintain tighter tolerances and minimize operational downtime. Moreover, their resistance to wear allows for extended tool life, leading to less frequent replacements and thereby reducing overall production costs.

Incorporating advanced tool materials also facilitates better chip management and machining performance. For example, ceramic tools excel in high-temperature settings, effectively dissipating heat during the cutting process. This capability allows for faster cutting speeds without compromising the integrity of the part being machined. Additionally, cermet tools, which blend ceramic with metallic elements, offer a unique combination of toughness and wear resistance, making them ideal for precision turning applications. By prioritizing the use of these advanced materials, manufacturers can significantly enhance the longevity of their tools while simultaneously improving the overall efficiency of their machining operations.

The article "Top 10 CNC Turning Techniques for Precision and Efficiency" provides a comprehensive overview of various techniques that enhance CNC Turning processes in precision manufacturing. It highlights key techniques such as utilizing live tooling, which allows for the creation of complex geometries, and optimizing feed rates to increase material removal efficiency. Additionally, the article emphasizes the importance of implementing multiple turning operations and incorporating advanced tool materials to improve the longevity of tools.

Furthermore, integrating CNC programming is discussed as a vital method for reducing errors and achieving greater accuracy in production. These techniques collectively contribute to achieving high precision and efficiency in CNC Turning, making them essential for manufacturers aiming to enhance their operational capabilities.