- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

CNC rotors play a crucial role in precision engineering and manufacturing. Choosing the right one can make all the difference. John Smith, a leading expert in the CNC rotors industry, once said, "The right rotor can enhance performance and extend the machine's lifespan." This highlights the importance of making an informed choice.

When assessing CNC rotors, several factors come into play. Material quality, design, and compatibility with your machinery are vital. Each element contributes to overall performance and durability. Ignoring these aspects can lead to costly mistakes and inefficient operations.

It's not just about picking a rotor; it's about understanding your specific needs. Many overlook this crucial step. Take time to research and analyze. Invest in a rotor that satisfies both your current and future requirements. Perfect choices are rare; reflecting on your decisions is essential in this complex field.

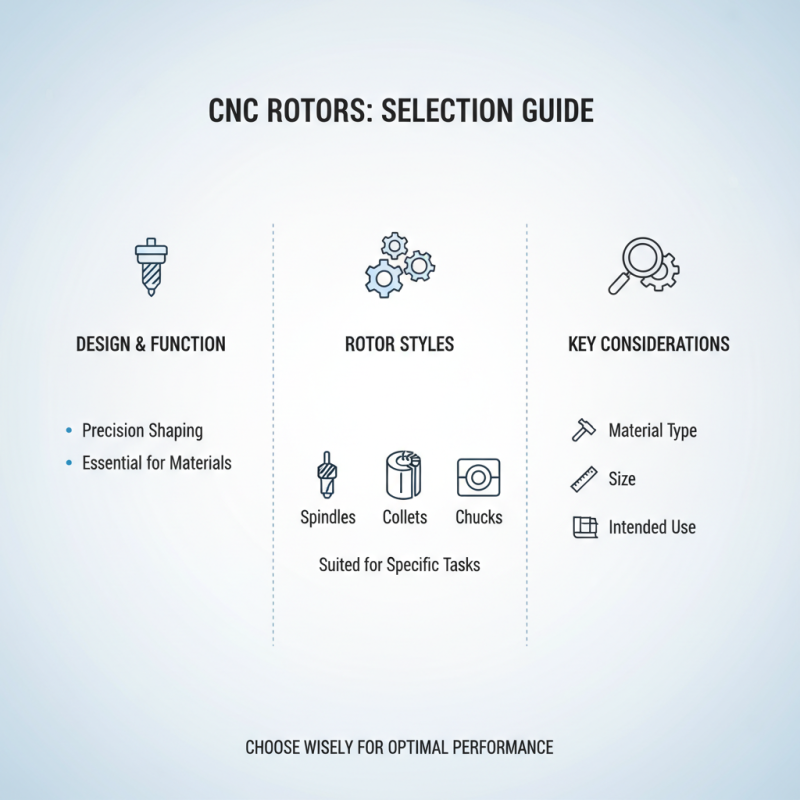

When selecting CNC rotors, understanding their design and function is crucial. CNC rotors are essential in shaping materials with precision. They come in different styles, each suited for specific tasks. Factors such as material type, size, and intended use should be considered carefully.

Different materials can yield varying results. A rotor made of high-grade steel may offer durability but could be heavier. Conversely, lighter materials can provide speed but may compromise strength. These trade-offs warrant careful thought. Additionally, the complexities of design often lead to oversights. Some users may overlook the importance of proper cooling. Ignoring this can lead to premature wear of the rotor.

The right CNC rotor enhances productivity. Yet, not all choices are straightforward. Users might choose based on only one feature. This could lead to inefficiencies. It's vital to analyze all aspects before making a decision. Consider consulting with experts when in doubt. Their insights can clarify many uncertainties. Understanding CNC rotors is a balanced process of knowledge and experience.

Choosing the right CNC rotor requires careful consideration of several factors. The material is crucial. High-quality materials like aluminum or carbon fiber can enhance performance. According to industry reports, a rotor's material can impact accuracy by up to 15%. This difference is significant in precision engineering.

Consider the rotor’s weight and balance as well. A well-balanced rotor reduces vibrations, enhancing machining quality. Reports indicate that unbalanced rotors can cause up to 20% more wear on CNC machines. This wear leads to increased maintenance costs and downtime, both of which are costly for any operation.

Finally, pay attention to compatibility with your CNC machine. Different models have distinct specifications. Ensuring compatibility may involve reviewing technical documentation carefully. Ignoring this could lead to inefficiencies and machine failures. Always verify specifications before making a decision. Challenging choices often arise when balancing performance and cost. Each project may require a different approach, making careful reflection essential.

Choosing the right material for CNC rotors can be challenging. Different materials come with unique advantages and drawbacks. Understanding these options is essential for optimal performance.

Aluminum is a popular choice for its lightweight and good thermal conductivity. It helps in reducing the overall weight of the rotor. However, aluminum may lack the durability required for high-stress applications. It can bend or dent easily under extreme conditions.

On the other hand, steel offers excellent strength and resistance to wear. It can withstand higher loads and provides durability. Yet, steel is heavier. It can affect the efficiency of the system, especially in dynamic applications. Material selection often requires balancing weight, strength, and cost. Different projects may highlight different needs. Reflecting on these factors is crucial. Choosing the wrong material could lead to inefficiencies or frequent replacements. Consider all aspects carefully before making a decision.

| Material | Pros | Cons |

|---|---|---|

| Aluminum | Lightweight, good thermal conductivity, corrosion-resistant. | Lower strength compared to steel, may deform under high loads. |

| Steel | High strength and durability, suitable for heavy-duty applications. | Heavier than other materials, prone to rust without proper coating. |

| Carbon Fiber | Very lightweight, high strength-to-weight ratio, and excellent fatigue resistance. | More expensive, can be brittle and sensitive to impact. |

| Titanium | Strong, lightweight, and highly corrosion-resistant. | Very costly, difficult to machine compared to other materials. |

| Plastic | Low cost, lightweight, and corrosion-resistant. | Low strength, not suitable for high-load applications. |

When selecting CNC rotors, precision and performance are critical factors. Industry reports highlight that precision directly affects machining accuracy. According to a study by the International Journal of Advanced Manufacturing Technology, a rotor's imbalance can lead to inefficiencies, resulting in up to 15% increased wear and tear on equipment.

Consider the material used in the rotor. Aluminum is lightweight and offers good thermal properties but may lack durability under extreme conditions. On the other hand, steel rotors provide enhanced strength but can add significant weight to the assembly. It's essential to assess your specific machining needs when choosing.

Tip: Always request samples to test. This can help you gauge performance firsthand. Understanding the stress and heat levels in your operations can guide you in selecting the right rotor composition.

Another critical aspect is rotor diameter and design. A larger rotor may improve performance at higher speeds but can complicate balancing. Miscalculations here can lead to vibrations, which may disrupt precision. Regular testing and adjustments are necessary to maintain optimal performance.

Tip: Measure performance regularly. Data from performance tests can reveal patterns and help inform future rotor selections. Finding the balance between precision and efficiency is key—achieving it might take some trial and error.

Maintaining CNC rotors is vital for optimal performance. Regular cleaning is essential. Dust and debris can build up over time. This accumulation affects rotor efficiency. Use a soft brush or cloth to eliminate particles. Be gentle to avoid damage.

Check the rotor's balance frequently. An unbalanced rotor can lead to vibrations. These vibrations cause wear and tear. If you notice unusual sounds, inspect the rotor immediately. Timely detection can prevent more significant issues.

Lubrication is another critical aspect. Apply appropriate lubricants to moving parts. However, too much lubricant can be detrimental. It may attract more dirt. Ensure you follow recommended guidelines for amounts used.

Keep a maintenance log for tracking performance and issues. This can help identify patterns needing attention. Regular checks and proactive maintenance extend the lifespan of CNC rotors significantly. It takes effort, but it’s worth it.