- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the ever-evolving landscape of modern manufacturing, precision and accuracy have become paramount as industries strive to meet the increasing demands for quality and efficiency. Central to achieving these high standards is the introduction of advanced technologies, among which CNC probes play a pivotal role. These sophisticated devices allow for real-time measurements and inspections, significantly enhancing the accuracy of manufacturing processes. According to a report by the International Journal of Advanced Manufacturing Technology, the integration of CNC probing systems has led to an improvement in dimensional accuracy by as much as 30% in various machining applications.

Moreover, as manufacturers adopt Industry 4.0 principles, the role of CNC probes becomes even more critical. They facilitate automated quality control and data collection, thereby reducing human error and streamlining workflows. Research from the National Institute of Standards and Technology indicates that employing CNC probes can decrease downtime by 20% and improve overall production efficiency. As companies look to maintain competitiveness in a global market, embracing CNC probe technology is not just a choice but a necessity for enhancing manufacturing accuracy and achieving operational excellence.

A CNC probe is a vital tool in modern manufacturing, designed to enhance precision and efficiency on CNC machines. This non-contact measuring device is used to automate the process of part inspection, significantly improving both speed and accuracy in quality control. By utilizing advanced sensing technology, a CNC probe can identify variances in dimensions, surface profiles, and geometries during the machining process, allowing for real-time adjustments that maintain the integrity of the manufacturing workflow.

The role of a CNC probe in manufacturing extends beyond mere measurement. It plays a crucial part in the overall quality assurance process, ensuring that parts meet specified tolerances and reducing the likelihood of defects. By integrating the probe into CNC operations, manufacturers can minimize manual inspection time and errors associated with human oversight. As a result, the overall productivity increases, along with the ability to implement consistent quality checks throughout production runs. This not only elevates the standard of the finished products but also leads to cost savings by reducing waste and improving resource allocation.

CNC probes are essential tools in modern manufacturing that enhance precision and accuracy in machining processes. The different types of CNC probes commonly used in the industry can be categorized primarily into three groups: touch probes, laser probes, and optical probes. Touch probes work by making physical contact with the workpiece to detect dimensions and features, making them particularly effective for detailed measurements. Laser probes, on the other hand, utilize a laser beam to measure distances and contours without physical contact, which is beneficial for delicate materials that could be damaged by touch. Finally, optical probes leverage light technology to capture high-resolution images of the workpiece, offering a non-invasive alternative to traditional probing methods.

Tips: When selecting a CNC probe, consider the material and size of your workpiece as well as the precision required for your project. It is also beneficial to evaluate the compatibility of the probe with your existing CNC equipment to ensure seamless integration and functionality.

The choice of a CNC probe can significantly influence the quality of production. For example, touch probes are often preferred for precise part setups, while laser probes may be better suited for rapid scanning of complex shapes. Understanding the strengths and limitations of each probe type can help manufacturers optimize their processes and improve overall manufacturing accuracy.

CNC probes are pivotal tools in modern manufacturing, providing significant enhancements in measurement accuracy. By integrating these advanced devices into the manufacturing process, companies can achieve precision levels that meet the stringent demands of industries such as aerospace and automotive. A report by the National Institute of Standards and Technology (NIST) indicates that the use of CNC probing technology can improve measurement accuracy by up to 90% in some applications. This level of precision is crucial, especially when even the slightest deviation can lead to costly reoperations and material wastage.

CNC probes operate by utilizing a contact or non-contact measurement technique to gather data on the dimensions and geometry of workpieces. The gathered data can then be used to adjust the machine settings automatically, minimizing human error and improving overall manufacturing efficiency. According to a study published by the International Journal of Advanced Manufacturing Technology, implementing CNC probes has led to a reduction in measurement uncertainty by as much as 30%, showcasing their capability to enhance quality control in production environments. This is vital for maintaining competitiveness in a global market, where precision and efficiency are paramount.

| Measurement Type | CNC Probe Type | Accuracy (µm) | Measurement Range (mm) | Application Areas |

|---|---|---|---|---|

| Touch Probe | Mechanical | 2-5 | 0-300 | Metalworking |

| Laser Probe | Optical | 1-3 | 0-200 | Plastic & Sheet Metal |

| Scanning Probe | Tactile | 3-10 | 0-500 | Automotive Components |

| Optical Probe | Non-contact | 1-2 | 0-150 | Electronics |

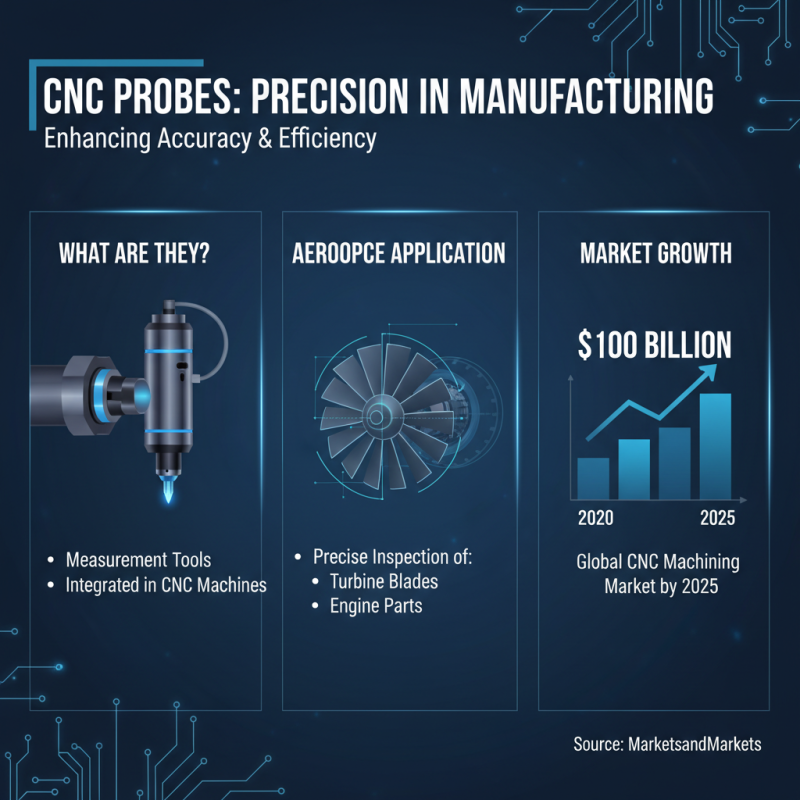

CNC probes are increasingly becoming essential tools in various manufacturing processes, enhancing measurement precision and process efficiency. In the field of aerospace, for instance, CNC probes play a crucial role in conducting precise inspections of intricate components such as turbine blades and engine parts. According to a report by MarketsandMarkets, the global CNC machining market, which incorporates CNC probing technology, is expected to reach $100 billion by 2025, fueled by the rising demand for accuracy in critical applications.

In the automotive industry, the implementation of CNC probes has revolutionized quality control processes. They allow manufacturers to perform real-time measurements, ensuring that components meet stringent specifications. With the capability to detect deviations as small as 1 micron, CNC probes significantly reduce the margin of error. The latest insights from the International Journal of Advanced Manufacturing Technology suggest that the integration of CNC probing systems can decrease inspection times by up to 50%, thereby accelerating production cycles and enhancing overall operational efficiency.

Furthermore, CNC probes find applications in the medical device manufacturing sector, where precision is paramount. The ability to accurately measure complex geometries ensures that components fit together seamlessly, which is critical for device functionality and patient safety. Reports indicate that manufacturers utilizing CNC probing technologies have seen a notable improvement in production accuracy, with reported increases in yield rates and reductions in scrap material. This is indicative of how CNC probes are transforming the landscape of manufacturing across various industries, ultimately leading to higher standards of quality and reliability.

The implementation of CNC probes in manufacturing processes can be met with several challenges that need to be addressed for successful integration. One major challenge is the calibration of the probes, which requires careful alignment to ensure accurate measurements. Misalignment can lead to errors in the inspection process, ultimately affecting the quality of the final product. To solve this, manufacturers can employ advanced calibration techniques, including the use of automated systems that can regularly check and adjust the probe's position, ensuring consistent accuracy.

Another challenge lies in the programming and operation of the CNC probes, which may necessitate advanced technical skills that are not always available within a manufacturing workforce. As a solution, companies can invest in comprehensive training programs that equip employees with the necessary skills to effectively operate and maintain probing systems. Additionally, utilizing user-friendly software that simplifies the programming of probes can facilitate easier deployment, allowing for a smoother transition into automated inspections and enhancing overall productivity.