- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Cnc Metal plays a crucial role in modern manufacturing. It refers to metals processed using Computer Numerical Control (CNC) technology. This method enhances precision and efficiency in metal fabrication.

Manufacturers rely on Cnc Metal for various applications. From automotive parts to intricate machinery components, the versatility is noteworthy. CNC machines execute designs with high accuracy, reducing waste and improving quality. However, mastering CNC technology can be challenging. The learning curve might hinder some businesses.

Despite these challenges, the benefits of Cnc Metal are clear. Companies that embrace this technology often achieve better results. It can lead to innovation and improved productivity. However, it necessitates skilled operators and maintenance. Overlooking these factors can compromise the advantages of Cnc Metal. Thus, careful consideration of resources is essential for success.

CNC metal is a key component in modern manufacturing. It refers to the metals that are machined using Computer Numerical Control (CNC) technology. This process allows for high precision cutting and shaping. Metals commonly used include aluminum, steel, and brass. Their properties vary, influencing their applications in various industries.

CNC machining offers consistent results, ensuring each piece meets strict specifications. This precision leads to better quality products. Nevertheless, achieving this requires proper calibration of CNC machines. Misalignment can cause defects. It’s essential to check machines regularly to maintain quality.

Tips: Always inspect the raw materials before starting. Look for any imperfections. Maintain your CNC machine well; cleaning it can prevent future issues. The type of metal selected should be suited for the intended use. Think about the environment too; some metals perform better under specific conditions. This consideration can impact product longevity.

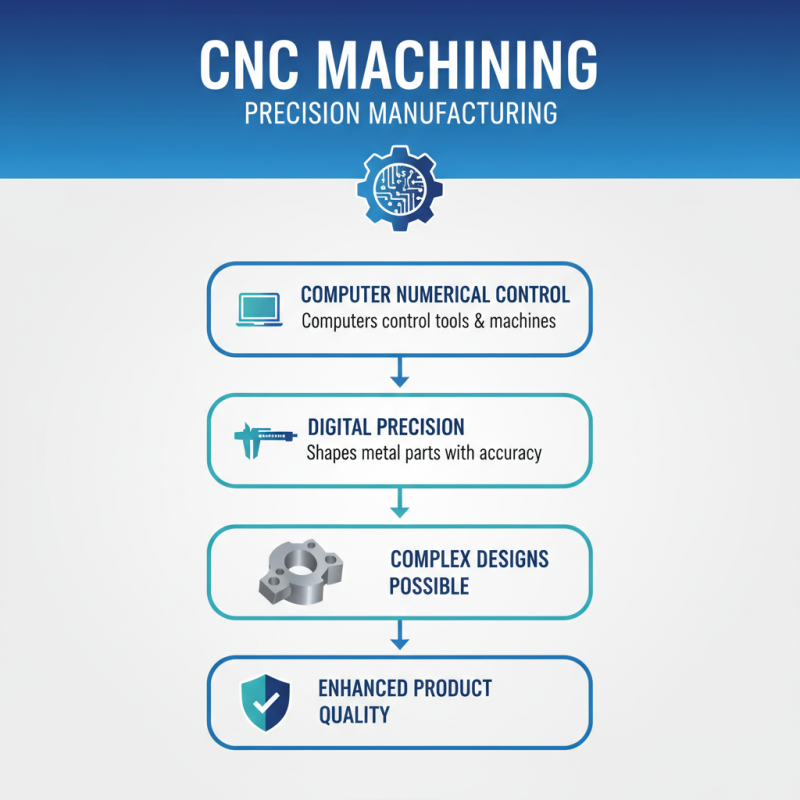

CNC machining is a vital part of modern manufacturing. It stands for Computer Numerical Control. This technology uses computers to control tools and machines. It allows for precision in shaping metal parts. Manufacturers can produce complex designs with high accuracy. This precision leads to better product quality.

However, CNC machining is not without its challenges. The setup process can be time-consuming. Operators need to carefully program machines. Any small error can lead to major issues. Additionally, there is a learning curve. New users must understand both software and hardware. Despite these hurdles, the benefits often outweigh the drawbacks.

In the manufacturing sector, CNC machining enhances productivity. It allows for rapid prototyping. This means businesses can test designs quicker. The automated nature of CNC reduces human error. But, it also requires skilled technicians to monitor the process. Balancing automation with skilled oversight remains crucial.

CNC machining utilizes various metals, each offering unique properties for different applications. Aluminum is lightweight and corrosion-resistant. It is often favored for parts requiring precision and durability. According to the 2022 Manufacturing Trends Report, aluminum accounts for nearly 40% of metals used in CNC machining.

Steel is another popular choice. Its strength makes it suitable for heavy-duty applications. Stainless steel, a subset of steel, provides excellent resistance to rust. It is commonly used in medical and food processing equipment. Metal compositions can vary, affecting performance and cost. In some cases, using less expensive metals may lead to quality trade-offs.

Copper and brass are not as common but have their niches. They offer excellent electrical conductivity. However, machining these metals can be challenging. Their softness may lead to tool wear and wasted material. Interestingly, a recent study found that about 15% of machined parts fail quality inspections. This indicates the need for a careful selection of materials and processes. Quality control remains crucial in CNC applications, as using inappropriate metals can affect end products significantly.

CNC metal machining has extensive applications across various industries. In automotive manufacturing, it enables precise components for engines, chassis, and body parts. This precision enhances vehicle performance and safety. In aerospace, CNC metal is essential for producing lightweight components, such as brackets and fittings, which require both strength and accuracy. The use of advanced machining techniques can help reduce weight while maintaining structural integrity.

In the medical field, CNC metal is crucial for crafting surgical instruments and implants. The precision of CNC machining ensures that these tools meet strict safety and effectiveness standards. However, challenges remain, such as ensuring consistent quality across batches. Some manufacturers struggle with machine calibration and material variability, which can lead to imperfections in the final product.

The electronics industry also benefits from CNC metal processes. Components for circuit boards and enclosures are often made using CNC techniques. Despite the advantages, there are ongoing debates about the sustainability of certain metals used in this process. Recycling and waste management in CNC machining need further improvement to minimize environmental impacts. This industry must address these concerns while continuing to innovate and adapt to new technologies.

| Industry | Application | CNC Metal Type | Benefits |

|---|---|---|---|

| Aerospace | Component Manufacturing | Aluminum Alloys | Lightweight and High Strength |

| Automotive | Engine Parts Production | Steel | Durability and Cost-Effectiveness |

| Electronics | Circuit Board Manufacturing | Copper | Excellent Conductivity |

| Medical | Surgical Instruments | Titanium | Biocompatibility and Strength |

| Construction | Structural Components | Reinforced Steel | High Load Bearing Capability |

CNC metal has transformed manufacturing processes. It stands for Computer Numerical Control. This technology uses precise machines to cut, shape, and form metal parts. The accuracy of CNC machines is remarkable. They operate with minuscule tolerances. This accuracy can lead to better product quality.

Using CNC metal in manufacturing offers several benefits. First, it enhances efficiency. Machines can run continuously, reducing production time. The process also minimizes waste. With precise cuts, there’s less scrap metal. However, the initial investment in CNC technology can be high. Not every business can afford it.

Another advantage is the flexibility it provides. CNC machines can produce complex designs that traditional methods struggle with. Customization becomes easier. Yet, this can also lead to over-reliance on technology. It’s vital to maintain a balance between manual skills and automation. Embracing CNC evolves manufacturing, but it also requires thoughtful consideration.