- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

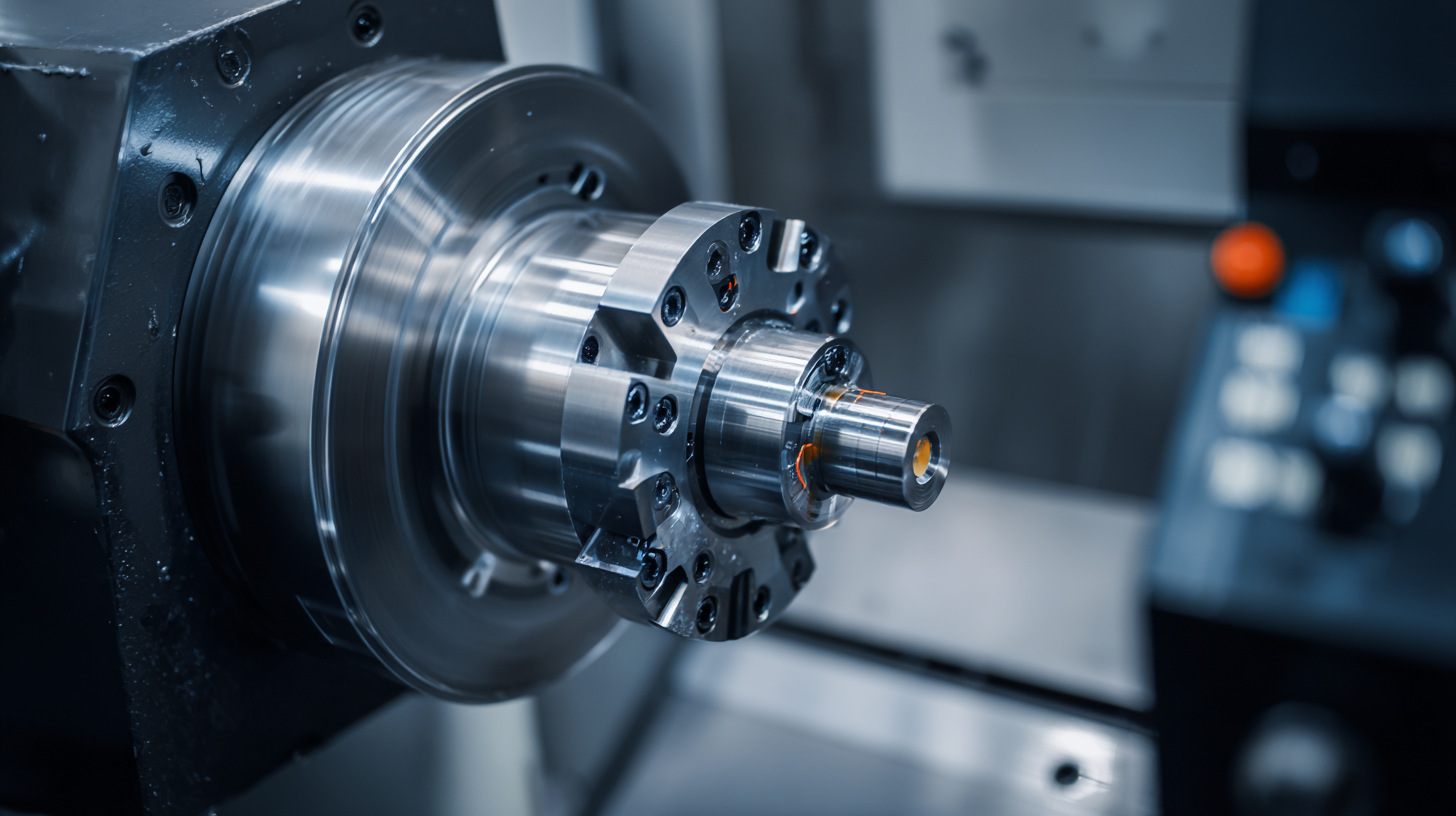

In the fast-paced world of manufacturing, CNC lathes play a crucial role in producing high-precision components across various industries, including aerospace, automotive, and electronics. According to a report by MarketsandMarkets, the CNC machining market is projected to reach $100 billion by 2025, indicating a robust demand for CNC technology. However, despite their advantages, operators frequently encounter common issues that can affect productivity and output quality.

These challenges range from improper tool selection and programming errors to machine maintenance and setup complications. Understanding these complications is essential for manufacturers seeking to optimize their CNC lathe operations and ensure consistent production standards. As we delve deeper into these common issues, it becomes clear that addressing them can lead to significantly enhanced efficiency and operational success in the manufacturing process.

CNC lathes play a pivotal role in modern manufacturing, but they are not without their challenges when it comes to achieving precision. One significant issue is the need for accurate real-time monitoring during machining operations. In-process measurement methods, such as monitoring force, geometry, and temperature, are critical for maintaining high standards of precision. However, the complexity of these measurements often poses difficulties, particularly in metal forming processes where component shapes can be irregular.

Furthermore, the integration of advanced technologies, such as digital twins, is helping mitigate some of the precision challenges faced by CNC lathe operators. Digital twins create a seamless connection between the virtual model and the actual machine, enhancing the prediction of outcomes and reducing the risk of operational collisions. This not only ensures the creation of high-precision parts but also streamlines maintenance processes in traditional manufacturing settings. As the demand for high-precision and multi-axis machining grows, leveraging innovations like machine learning for fault diagnosis and predictive analysis will be essential for overcoming the inherent challenges in CNC lathe operations.

When utilizing CNC lathes in manufacturing, one of the most critical factors affecting production efficiency is tool wear. This phenomenon is not only inevitable but can also significantly impact both productivity and product quality. According to a report by the Manufacturing Technology Association, tool wear can lead to a decline in machining precision, causing dimensional inaccuracies that force manufacturers to scrap parts or adjust processes. In fact, studies indicate that inappropriate tool wear management can increase costs by up to 25% over time due to diminished output and rework requirements.

Understanding the stages of tool wear is essential for optimizing CNC lathe operations. Research conducted by the International Journal of Advanced Manufacturing Technology reveals that the rate of wear varies with material type, cutting speed, and feed rate. For instance, tools operating at higher speeds on harder materials typically experience accelerated wear. Implementing predictive maintenance strategies based on real-time monitoring and wear analysis can mitigate these challenges. By proactively addressing tool wear, manufacturers can enhance production efficiency and reduce operational costs, ultimately leading to higher profitability in competitive markets.

The performance of CNC lathes in manufacturing is critically influenced by the workpiece material being processed. According to a report by the International Journal of Machine Tools and Manufacture, nearly 40% of machining issues can be attributed to material properties. Different materials, from soft alloys to hardened steels, exhibit varying levels of machinability, which can significantly affect tool wear, surface finish, and overall machining efficiency.

For instance, materials with high hardness, such as titanium alloys, often require specialized cutting tools and slower feed rates to prevent excessive tool wear and maintain precision. A study by the Society of Manufacturing Engineers found that using the correct tool material and geometry can improve tool life by up to 50% when machining challenging materials. On the other hand, softer materials such as aluminum can result in faster machining speeds but may also lead to issues such as chip build-up, which can compromise the performance of the CNC lathe. Understanding these material-specific behaviors is crucial for manufacturers to optimize their CNC lathe operations and achieve desired production outcomes.

CNC lathes are integral to modern manufacturing, but they often grapple with vibration issues that can adversely affect precision and product quality. The recent study on the frequency response of CNC lathe spindles highlights that excessive vibrations can lead to detrimental outcomes in both cutting accuracy and tool lifespan. According to research, effective vibration monitoring and control mechanisms, such as utilizing MEMS sensors, can significantly enhance the operational stability of CNC machines.

To mitigate vibration effects, manufacturers should consider implementing specific strategies. One effective method is the optimization of machine parameters, which has shown promise in reducing vibration levels during automatic tapping operations. Moreover, denoising techniques like those based on variational mode decomposition can help in cleaning the signal outputs from machining processes, ensuring clearer data for analysis.

**Tips:**

1. Regularly monitor vibration levels using advanced sensor technologies to preemptively identify and address issues.

2. Optimize machining paths and parameters to minimize the occurrence of vibrations, fostering a smoother operational workflow.

3. Stay updated with the latest research findings, as advancements in vibration control techniques can lead to significant improvements in CNC lathe performance.

This chart illustrates the common vibration issues faced during CNC lathe operations and their impact on product quality. The data represents the frequency of reported vibration problems in various categories, showcasing the necessity for effective mitigation strategies.

When utilizing CNC lathes in manufacturing, diagnosing malfunctions can be a challenging yet crucial task. One common issue is tool wear, which can lead to inconsistencies in product dimensions and surface finishes. To diagnose this, operators should regularly measure tool life using a tool monitoring system, which tracks wear and can alert manufacturers when tools need replacing. Additionally, visual inspections for signs of damage can prevent further production delays.

Another frequent problem is software or programming errors, which can cause the machine to execute incorrect commands. To address this, it’s essential to utilize simulation software to ensure the CNC program behaves as expected before running it on the machine. Running test pieces can also help identify potential issues without wasting materials. By integrating these diagnostic techniques into regular maintenance routines, manufacturers can minimize downtime and ensure consistent production quality.

| Issue | Description | Diagnostic Technique | Potential Solution |

|---|---|---|---|

| Vibration Issues | Excessive vibration during operation can lead to poor machining accuracy. | Check for loose bolts and misalignment of components. | Tighten all bolts and adjust alignment settings. |

| Tool Wear | Tools can wear out quickly, reducing the quality of the finish. | Regularly inspect tools and measure cutting edge conditions. | Replace worn tools and adjust cutting speeds. |

| Overheating | Overheating can cause component damage and reduce machining precision. | Monitor temperature readings and coolant flow rates. | Ensure adequate coolant supply and machine ventilation. |

| Inaccurate Measurements | Parts may not meet specifications due to inaccurate measurements. | Use precise measuring tools and verify settings. | Calibrate measuring instruments and check CNC settings. |

| Software Errors | Software bugs can disrupt operation and lead to programming errors. | Regularly update software and conduct error checks. | Implement a software maintenance schedule and training. |