- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

A CNC Flywheel is a crucial component in various machinery. It plays a vital role in energy storage and distribution. Its design and construction significantly affect performance.

In the world of manufacturing, precision is everything. The CNC Flywheel must be made with exact specifications to ensure efficiency. Even a slight imperfection can lead to failures. This highlights the importance of high-quality materials and advanced machining techniques.

Moreover, understanding the application of a CNC Flywheel can help industries optimize their processes. Different types of machines rely on this component. The right design can improve functionality. However, not all designs are flawless. Continuous improvement is necessary in the industry to address these challenges.

CNC flywheels are precision-engineered components commonly used in automotive and machinery applications. They play a critical role in energy storage and management. A CNC flywheel reduces vibrations and optimizes energy transfer within engines. The manufacturing process ensures high accuracy, which in turn enhances performance. It's estimated that well-designed flywheels can improve energy efficiency by up to 15%.

Moreover, the weight and balance of a flywheel significantly impact the overall system's performance. Heavy flywheels store more energy but can be less responsive. Lightweight options allow for quicker acceleration but may not provide sufficient energy retention. For example, studies show that a well-balanced CNC flywheel can lead to a 10% increase in torque output. Refining the design of these components can be a complex task, often leading to trade-offs between weight and durability.

Additionally, while CNC technology offers enhanced precision, it can be costly. The equipment and setup require significant upfront investment. Manufacturers need to weigh the benefits against the costs. Mistakes in the design process can lead to inefficiency or failure in performance. Continuous improvement and testing are necessary. Adapting to technological advances is also vital, as new materials and methods emerge. The importance of a CNC flywheel extends beyond just performance; it embodies the intersection of engineering, refinement, and energy management.

CNC flywheels are crucial components in various machinery. Their manufacturing process is intricate and requires precision. Computer Numerical Control (CNC) technology allows for accuracy that traditional methods struggle to achieve. Reports indicate that CNC manufacturing can improve tolerance levels to as fine as 0.005 mm. This level of precision ensures high efficiency in mechanical applications.

The manufacturing process starts with selecting quality materials. Commonly used materials include metals like aluminum or steel, which provide strength and durability. The raw material is shaped using CNC machines. These machines follow detailed CAD (Computer-Aided Design) models. The process includes milling, drilling, and turning. Each step must be monitored closely. A slight deviation can result in part failure.

Despite advancements, the process is not flawless. Operators must frequently calibrate machines and check for wear. Regular quality control is imperative, as even small errors can lead to significant problems. There's always room for improvement in training staff on technology use. Inconsistent skill levels can affect production quality. Overall, mastering the CNC manufacturing process of flywheels requires ongoing effort and attention to detail.

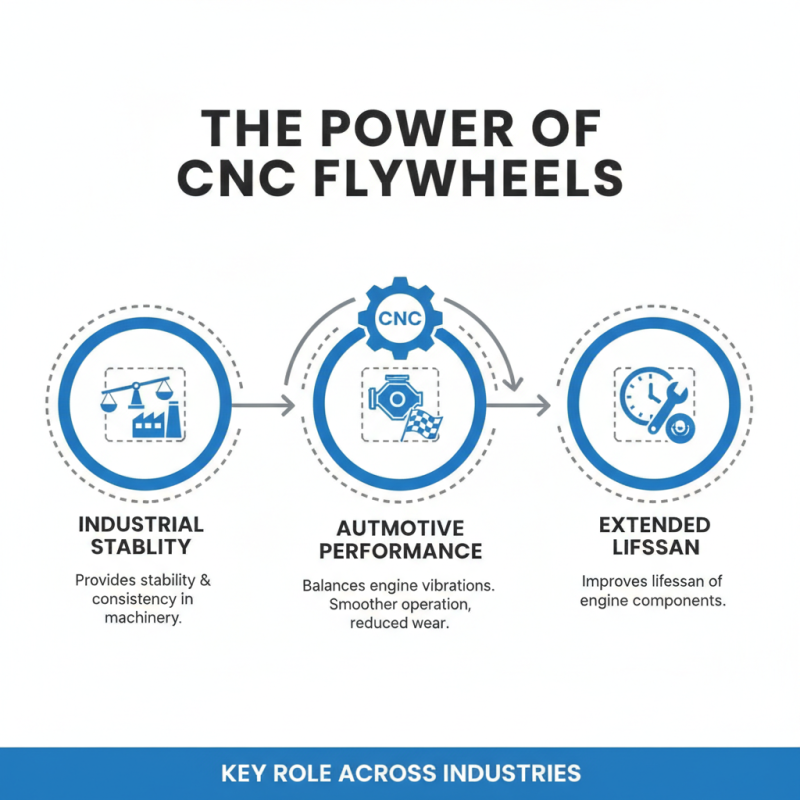

CNC flywheels are crucial for automotive performance. These components are precision-engineered using CNC machining technology. They enhance the efficiency of an engine by optimizing its weight and balance. A well-designed flywheel aids in smoother power delivery. This creates a better driving experience overall.

The importance of CNC flywheels goes beyond just weight savings. They also impact how quickly an engine revs. A lighter flywheel helps achieve faster acceleration. Drivers often notice a more responsive throttle. However, lighter isn’t always better. In some cases, it can make driving less stable. This balance of weight must be carefully considered.

Precision in manufacturing is essential. A poorly made flywheel can lead to vibrations. This may cause increased wear on other engine components. It’s a detail that can make a big difference. Without attention to this aspect, performance can suffer greatly. CNC flywheels offer an impressive solution, but they require ongoing reflection on design and function.

CNC flywheels play a critical role in various industries. They provide stability and consistency in machinery. In automotive manufacturing, they enhance performance by balancing engine vibrations. This leads to smoother operation and reduced wear and tear. A well-designed flywheel can significantly improve the lifespan of engine components.

In aerospace, CNC flywheels are vital for precision equipment. They ensure reliable operation in high-speed environments. The aerospace sector demands optimized performance under extreme conditions. Using CNC technology allows for meticulous design adjustments. However, some manufacturers struggle with the accuracy of their components. Flaws can lead to catastrophic failures, raising concerns about safety.

In renewable energy sectors, such as wind and solar, CNC flywheels store energy efficiently. This technology makes it possible to harness energy during peak times. Companies often face challenges in integrating flywheels with existing systems. Compatibility issues can arise, making implementation difficult. Despite these obstacles, the potential for improvement is significant. The future holds promise for further innovations in flywheel applications across diverse industries.

CNC flywheels have gained traction in the automotive industry. They are precision-engineered components made using computer numerical control technology. Traditional flywheels are often cast or forged, which can lead to inconsistencies. CNC flywheels, however, are crafted with high precision. This accuracy improves performance and enhances durability. A study by the Society of Automotive Engineers (SAE) shows that CNC manufacturing can increase part strength by up to 15% compared to traditional methods.

The weight distribution in CNC flywheels is another significant advantage. Traditional flywheels can have uneven weight distributions, leading to vibrations and noise. Studies reveal that CNC flywheels often exhibit more balanced characteristics, reducing wear on the engine. Engine efficiency can increase by as much as 5% with better-balanced flywheels. Despite these advantages, the cost of CNC flywheels can be a concern. They tend to be pricier than traditional ones, potentially limiting their widespread adoption.

In the end, while CNC flywheels showcase clear benefits in terms of performance and durability, some may question their value. The added cost versus increased efficiency needs careful consideration. Consumers might find themselves grappling with the decision of investing in cutting-edge technology or sticking to conventional solutions. More data on long-term reliability may also be required for a complete understanding.