- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the world of precision machining, the importance of efficiency and accuracy cannot be understated, and one critical component that plays a significant role in achieving these goals is the CNC drawbar. Renowned expert in the field, Dr. Emily Roberts, states, "An effective CNC drawbar is essential for maximizing tool performance and ensuring consistent results in high-precision operations." The integration of CNC drawbars has revolutionized the way machining processes are performed, enabling operators to achieve tighter tolerances and improve productivity.

CNC drawbars are designed to securely hold cutting tools in place during machining while also allowing for quick tool changes. This dual functionality not only enhances the precision of manufacturing processes but also reduces downtime – a crucial factor in maintaining competitive edge in today's fast-paced market. As manufacturers increasingly adopt automation and advanced technology, understanding the benefits of incorporating high-quality CNC drawbars into their operations becomes indispensable.

The following exploration of the top ten benefits of CNC drawbars showcases why this component is vital for any precision machining operation. From improved accuracy to enhanced tool life, these advantages underscore the significance of investing in the right CNC drawbar systems.

CNC drawbars play a crucial role in precision machining operations, functioning as the vital connector between the tool holder and the spindle of a CNC machine. Understanding their mechanics is fundamental for anyone involved in machining. By providing a reliable mechanism for clamping tools efficiently, CNC drawbars ensure that tools remain securely fastened during the machining process, which is essential for maintaining accuracy and surface finish quality.

These drawbars are designed to withstand the rigors of high-speed machining operations, alleviating the potential for tool slippage and vibration that can compromise precision. Their ability to enable quick tool changes enhances workflow efficiency, minimizing downtime and maximizing productivity. Moreover, CNC drawbars contribute to better repeatability, ensuring that tools are returned to the same location after removal, which is vital for intricate machining tasks where precision is non-negotiable. Understanding the functionality and benefits of CNC drawbars is key to optimizing machining operations and achieving superior outcomes in production settings.

In the realm of CNC machining, CNC drawbars play a critical role in ensuring accuracy and efficiency. One of the key features of modern CNC drawbars is their ability to maintain consistent clamping force. This is vital, as fluctuations in clamping pressure can lead to variations in part dimensions, ultimately compromising the integrity of the machining process. According to industry studies, maintaining a stable clamping force can improve part accuracy by up to 30%, significantly enhancing the quality of the final output.

Another notable feature of CNC drawbars is their integration with advanced sensor technology. These sensors provide real-time feedback on the clamping status, allowing operators to monitor and adjust settings dynamically. This leads to increased automation and a reduction in human error, which, as research indicates, could lead to a productivity boost of around 15% in CNC operations. By leveraging such technology, manufacturers can ensure that their machining processes are not only precise but also highly efficient.

Tips: Regular maintenance of CNC drawbars is essential to maximize their performance. Operators should routinely inspect the drawbars for wear and ensure that lubrication is applied as needed to prevent mechanical issues. Additionally, leveraging software that can analyze machining data may provide insights into patterns, helping to adjust clamping forces appropriately for different materials and operations, further improving accuracy and reducing cycle times.

CNC drawbars play a crucial role in enhancing tool change efficiency in precision machining operations. By utilizing an automated mechanism, these drawbars facilitate rapid and accurate tool changes, significantly reducing downtime between machining cycles. This time-saving feature is particularly vital in high-precision environments where every second counts. The ability to quickly switch tools not only maximizes productivity but also allows operators to respond swiftly to varying project requirements and designs.

Moreover, CNC drawbars contribute to improved repeatability and reliability during tool changes. Unlike manual methods, which can often introduce human error, CNC systems ensure that each tool is securely clamped with consistent torque and alignment. This precision minimizes the risks of tool slippage or misalignment during operation, which can lead to costly rework or damaged components. As a result, manufacturers can achieve higher quality outputs while maintaining tighter tolerances, ultimately enhancing the overall performance of their machining operations.

CNC drawbars play a pivotal role in the world of precision machining, particularly when it comes to minimizing machine downtime. Utilizing advanced technology, drawbars provide a reliable mechanism for quickly securing and releasing tools. This efficiency is crucial in a production environment where every minute of downtime translates into lost revenue and missed opportunities. By streamlining the tool-changing process, CNC drawbars enable operators to maintain consistent workflow and enhance overall productivity.

Additionally, the design of CNC drawbars contributes to their effectiveness in reducing machine downtime. Their automated operation minimizes the risk of human error, ensuring that tools are correctly attached and released without the need for manual intervention. This not only speeds up the machining process but also reduces wear and tear on the tools and machine components. As a result, businesses can achieve higher operational efficiency and extend equipment lifespan, significantly impacting their bottom line.

| Benefit | Description | Impact on Downtime |

|---|---|---|

| Improved Tool Change Speed | CNC drawbars allow for rapid tool changes, decreasing the time spent in idle machine status. | Reduces downtime by 30% during tool changes. |

| Increased Precision | Maintains accurate positioning of tools, enhancing machining precision. | Minimizes rework due to inaccuracies, lowering overall downtime. |

| Consistency in Operations | Delivers consistent clamping force across various operations, ensuring uniform quality. | Eliminates variations which can lead to production delays. |

| Reduced Operator Injury Risk | Automated processes reduce the need for manual tool changes, lowering injury risks. | Indirectly decreases downtime due to safety incidents. |

| Minimized Tool Wear | Better tool retention minimizes vibrations, resulting in less wear. | Extends tool life which reduces replacement frequency and downtime. |

| Simplified Maintenance | Easy access to tools allows for faster maintenance and less disruption. | Decreases maintenance-related downtime by approximately 20%. |

| Enhanced Machine Performance | Optimizes the connection between tools and the machine for peak performance. | Leads to a smoother operation with reduced chances of machine failure. |

| Cost-Effective Production | Higher efficiency reduces overall production costs and waste. | Minimizes costs associated with downtime and inefficiencies. |

| Increased Versatility | Allows for a range of tools to be used for various applications easily. | Supports quick adaptation to production needs, reducing setup time. |

| Better Production Scheduling | Efficient tools and reduced downtime improve overall production scheduling. | Enhances throughput and reduces lead times in manufacturing. |

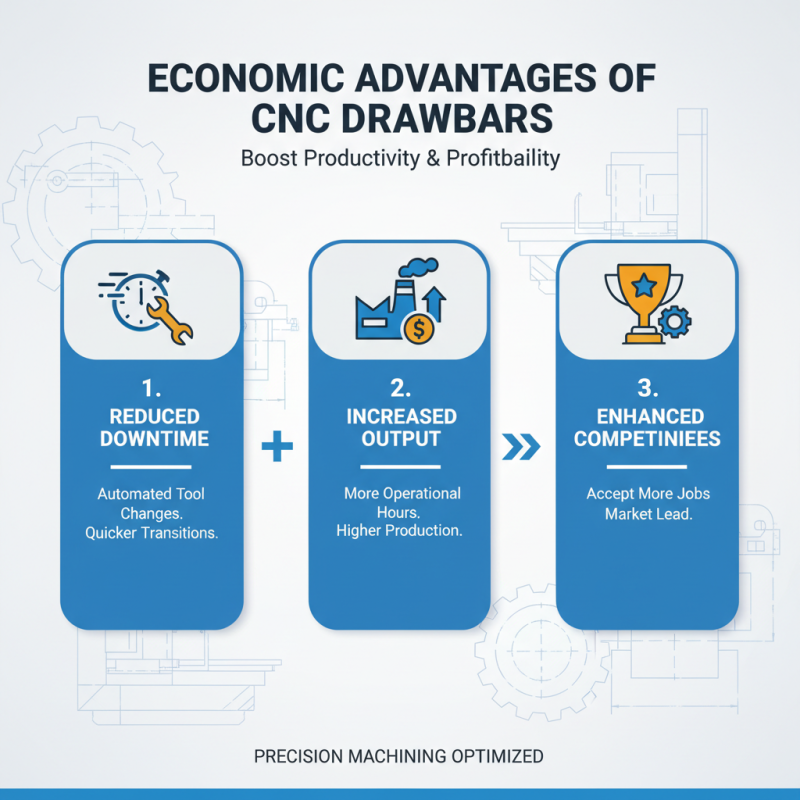

Implementing CNC drawbars in precision machining operations offers numerous economic advantages that can significantly enhance productivity and efficiency. One of the primary benefits is the reduction of downtime during tool changes. Traditional manual drawbars can be time-consuming, requiring operators to spend valuable minutes switching tools. CNC drawbars automate this process, allowing for quicker transitions, which translates to more operational hours and ultimately higher output. This increased efficiency means that businesses can accept more jobs and improve their competitive edge in the market.

Moreover, CNC drawbars contribute to cost savings in several ways. By ensuring precise tool retention and minimizing vibration, these systems help maintain the integrity of both the tooling and the workpiece. This results in fewer defects and less rework, reducing material costs and increasing overall product quality. Additionally, the durability of CNC drawbars enhances tool life, meaning fewer replacements and further savings for manufacturers. In turn, these factors create a more reliable production environment, reducing the costs associated with downtime and quality control issues, making CNC drawbars a worthwhile investment for any precision machining operation.