- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the realm of modern manufacturing, the efficiency and precision of processes are paramount, and one crucial component that stands out in enhancing these attributes is the CNC drawbar. This seemingly simple yet vital device plays an integral role in securing and manipulating tools within CNC machines, directly influencing production quality and operational reliability. However, as the demand for precision machining escalates, various problems associated with CNC drawbar implementations have surfaced, impacting overall manufacturing effectiveness.

This blog delves into the intricate applications of CNC drawbars in contemporary manufacturing settings, complemented by statistical insights that outline challenges and solutions. By examining these issues, we aim to provide a comprehensive understanding of how resolving CNC drawbar-related problems can lead to substantial improvements in efficiency and productivity within the industry.

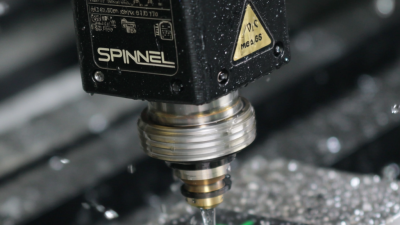

CNC drawbars play a crucial role in modern manufacturing, serving as an essential component in CNC machines. A CNC drawbar is a mechanism that holds tooling—be it end mills, drill bits, or other cutting instruments—in a secure and precise manner. Its primary function is to control the tool clamping process, ensuring that tools are firmly attached to the machine spindle during operation. This high level of clamping force not only enhances tool stability but also significantly impacts the quality of finished parts and overall machining precision.

Understanding the key functions of a CNC drawbar is vital for manufacturers looking to optimize their production processes. One of its essential attributes is the ability to enable quick tool changes, minimizing downtime and increasing efficiency. Moreover, CNC drawbars are designed to maintain consistent force application, which is crucial for effective cutting and minimizing tool wear. Additionally, advancements in drawbar technology, such as the integration of sensors and automated mechanisms, are paving the way for smarter manufacturing environments, where data-driven insights allow for proactive maintenance and improved operational performance.

The significance of CNC drawbars in contemporary manufacturing processes cannot be overstated. As the demand for precision and efficiency in production grows, CNC (Computer Numerical Control) machines have become vital in various industries. The global lathe machine market, valued at $25.01 billion in 2018, is forecasted to reach $57.54 billion by 2032, with a compound annual growth rate (CAGR) of 5.6%. This trend underscores the increasing reliance on advanced CNC technologies, which enhance productivity and streamline operations.

CNC drawbars are crucial components that facilitate quick tool changes and improve the overall efficiency of CNC machining processes. Their role becomes even more critical as manufacturers aim for more automated solutions to meet rising production demands. The CNC machine market alone is projected to grow from $27.16 billion in 2025 to $44.64 billion by 2033, fueled by the industry's shift towards digital manufacturing technologies. With advanced CNC controllers enabling this transition, the incorporation of CNC drawbars will be instrumental in achieving the high precision and speed that modern manufacturing requires.

CNC drawbars play a crucial role in modern manufacturing, particularly in enhancing machine efficiency and performance metrics. Recent studies have highlighted the importance of optimizing drawbar characteristics to improve productivity. For instance, analyzing the impact of tractor drawbar height reveals that adjustments lead to significant changes in pulling force and fuel efficiency. Such insights underscore the essentiality of fine-tuning drawbar specifications based on specific operational needs.

When considering CNC drawbars, manufacturers should focus on key performance indicators like force output and energy consumption. Implementing response surface methodology can help in determining the optimal settings. This statistical approach allows manufacturers to visualize the relationship between drawbar adjustments and performance metrics, leading to more informed decisions.

Tip: Regularly review and adjust drawbar heights to maintain optimal performance levels. Tip: Utilize data analytics to monitor performance metrics consistently; this will help in identifying trends over time. Tip: Engage with statistical methods to simulate different drawbar settings without the risk of disruption to ongoing operations.

In contemporary manufacturing, the evolution of CNC technologies has facilitated a shift from traditional mechanisms to more sophisticated solutions like the CNC drawbar system. A comparative analysis reveals that CNC drawbars exhibit superior performance in terms of speed, precision, and operational versatility. Recent studies indicate that modern CNC drawbars can achieve locking times as low as 1 second, significantly reducing setup time compared to traditional systems, which often require up to 5 seconds. Moreover, the integration of advanced electromechanical actuators enhances the reliability and responsiveness of CNC operations, increasing production efficiency.

In addition, the development of high-speed spindles, as evidenced by research from a leading university, showcases the transformative impact of CNC technology. These spindles offer rotational speeds exceeding 40,000 RPM, which allow for intricate machining processes that traditional equipment cannot perform efficiently. The adoption of CNC drawbars not only optimizes the machining process but also minimizes tool wear and operational costs—a critical consideration in competitive manufacturing environments. As the industry continues to evolve, the integration of CNC drawbar systems and advanced spindles stands as a testament to the relentless pursuit of efficiency and precision in modern manufacturing.

| Criteria | CNC Drawbar | Traditional Mechanisms |

|---|---|---|

| Operating Speed (cycles/min) | 120 | 80 |

| Tool Change Time (sec) | 5 | 12 |

| Maintenance Frequency (months) | 6 | 3 |

| Cost Efficiency (%) | 30 | 15 |

| Setup Time (hours) | 1 | 2.5 |

| User Satisfaction Rating (out of 10) | 9 | 6 |

The evolution of CNC drawbar technology is poised to revolutionize the manufacturing landscape. As industries seek greater efficiency and precision, innovations in drawbar designs and materials are emerging. Manufacturers are increasingly adopting advanced materials that not only enhance strength and durability but also reduce maintenance costs. Technologies such as additive manufacturing allow for the production of complex geometries that can improve performance and reduce weight, thus optimizing machine operation.

Moreover, the integration of smart technology, including IoT and AI, into CNC drawbars is set to transform traditional manufacturing processes. These innovations enable real-time monitoring and predictive maintenance, significantly minimizing downtimes and maximizing productivity. As companies collect and analyze statistical insights from machine performance, they can make informed decisions that lead to better operational efficiencies and quality control. The future of CNC drawbar applications will thus be defined by an intelligent synergy of mechanical excellence and cutting-edge technology, positioning manufacturers to meet the demands of an increasingly competitive market.

This bar chart illustrates the percentage usage of CNC drawbar applications across different manufacturing sectors. The automotive industry leads with 30%, followed by aerospace and tooling, while medical and consumer electronics have comparatively lower usage.