- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

CNC technology has transformed the manufacturing landscape. A crucial component of this technology is the CNC collet. This tool holds a workpiece securely during machining processes. It ensures precision and accuracy, essential for high-quality results.

The CNC collet operates on a simple yet effective principle. When tightened, it grips the workpiece firmly. This mechanism prevents any shifting during operations, reducing errors. Different sizes of collets cater to various needs. It is vital for machinists to select the right collet for their tasks.

However, choosing a CNC collet isn't always straightforward. Some may overlook the importance of compatibility with their equipment. A mismatched collet can lead to poor performance. Understanding the nuances of CNC collets requires experience and knowledge. Continuous learning is necessary to master this essential tool.

CNC collets are crucial for holding tools in machining processes. They are precision cylindrical sleeves designed to secure a tool tightly in place. When it rotates, a collet maintains the tool's position, preventing any wobbling or movement. This stability is essential, especially during high-speed operations.

These collets typically fit into the spindle of a CNC machine. They come in various sizes and designs, depending on the tool being used. Often, users overlook the importance of selecting the right collet. Incorrect sizing can lead to tool slippage. This can result in poor machining quality and wasted material.

Understanding how a CNC collet works is not just technical; it requires practice and experience. One must align the tool and collet properly. A slight misalignment can cause issues. Regularly inspecting collets for wear and tear is important. A worn collet may not hold the tool securely, leading to dangerous situations. Investing time in learning about these small but significant components can drastically improve machining outcomes.

A CNC collet is a tool holder that provides a secure grip for cutting tools. It consists of several key components. The most noticeable part is the collet body. This cylindrical piece is designed for precise fitting and stability. It ensures the tool remains in place during machining processes.

Inside the collet, you'll find a set of gripping fingers. These fingers contract to hold the tool tightly. The action is controlled by the collet nut, which must be tightened properly. This is sometimes overlooked. If the nut isn't secured well, the tool might slip. Proper alignment is crucial here. Misalignment can result in reduced accuracy and quality of work.

Another essential component is the taper design. This feature allows for quick tool changes and enhances stability. The precise angle of the taper ensures a snug fit. However, users often forget to check for wear and tear on the collet over time. Regular inspection is vital for maintaining performance. Ignoring these details can lead to inconsistencies in finished products.

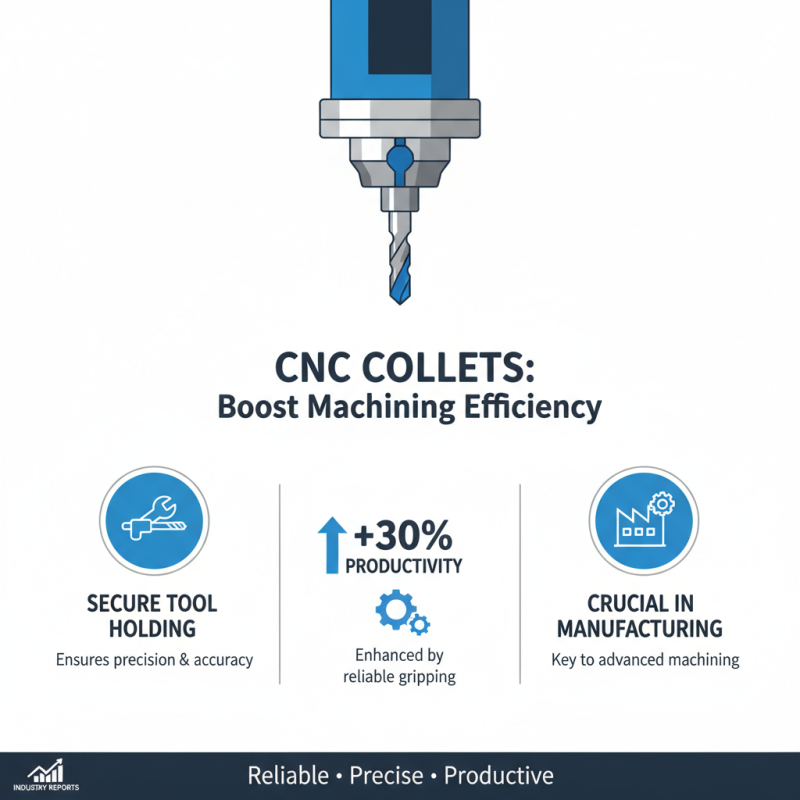

CNC collets are essential for precision machining. They grip and hold tools with accuracy. Understanding how they function is crucial for any operator. The mechanism involves a tapered design that tightly secures the tool when the collet is tightened. This creates a strong hold, essential for high-speed operations. According to industry reports, proper collet use can enhance efficiency by up to 30%.

The operation relies on the principle of friction. Collets are made of durable materials, ensuring longevity under stress. As the collet compresses, the tool shank is grasped firmly. This helps in maintaining stability during machining processes. However, improper use can lead to misalignment. An aligned tool can reduce wear on both the collet and the tool itself. Misalignment may cause tool failure, leading to costly downtime.

Some factors can impact collet performance. Dirt or debris in the collet can reduce gripping force. Regular inspection and cleaning are necessary to maintain function. Adjusting the collet to fit the tool correctly is important. Over-tightening may lead to deformation, compromising its integrity. Operators often overlook these details, but they can significantly affect output quality.

| Dimension | Specification | Function | Material |

|---|---|---|---|

| Collet Size | ER32 | Holds various tool shank sizes | Steel |

| Taper | BT40 | Aligns tools for precision | Alloy |

| Max RPM | 12,000 | Operational speed limit | Sintered Steel |

| Clamping Range | 1/8" to 1/2" | Versatility in tool holding | Carbon Steel |

| Collar Design | Slotted | Even pressure distribution | High-Performance Steel |

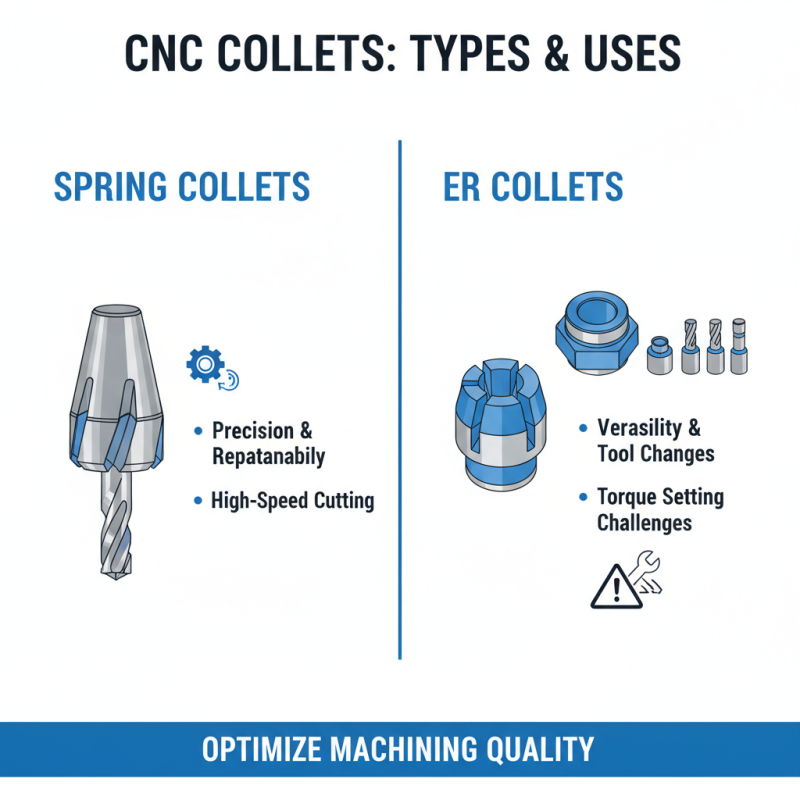

CNC collets come in various types, each serving distinct purposes in machining. The most common are spring collets, which grip tools tightly. They provide precision and repeatability, making them essential for high-speed cutting. Another type is the ER collet, known for its versatility. ER collets can hold different sizes of tooling, which helps reduce setup time. However, some users may struggle with the proper torque settings. This can lead to inadequate tool retention and impact machining quality.

For specialized tasks, there are also collets designed specifically for specific materials or processes. For instance, mill collets are tailored for milling machines, while lathe collets are optimized for lathes. Their unique designs allow for better grip on specific tools. Sometimes, operators may find that using the wrong collet leads to excessive vibration or poor finish quality. It's an important aspect to keep in mind when selecting a collet.

Manufacturers continuously innovate, but not all designs meet every need. Some collets are tricky to adjust and require a learning curve. Users often overlook maintenance, which can affect lifespan. Finding the perfect fit requires trial and error. It’s a reminder that even small components can significantly influence the end result in CNC machining.

CNC collets play a crucial role in machining processes. They are used to securely hold tools in place during operation. This ensures precision and accuracy in manufacturing. According to recent industry reports, using CNC collets can enhance productivity by up to 30%. This improvement is largely due to their reliable gripping capabilities.

One of the main advantages of CNC collets is their versatility. They can accommodate a range of tool sizes and shapes. This adaptability allows for quick changes during production runs. Some studies indicate that facilities using collets experience less downtime. However, improper use or maintenance can lead to tool slippage. Regular inspections are necessary to ensure optimal performance.

Moreover, CNC collets provide consistent force distribution. This minimizes vibration and improves finish quality. On the downside, if they are not correctly matched with the tool, issues can arise. This could lead to increased wear and tear or even equipment damage. This highlights the importance of proper selection and care in using collets effectively.