- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Choosing the right CNC end mill is crucial for the success of your machining project. According to David Carter, a renowned expert in CNC machining, “The right end mill can transform your project’s efficiency and precision.” Selecting the appropriate CNC end mill involves considering various factors, including material type and desired finish.

When you start, think about the material you’ll be cutting. Different materials require different end mill types. For example, harder materials need more durable tools. The geometry of the end mill also matters. Flute design and coating can significantly impact performance. A mismatch here could lead to poor results or even tool failure.

You might find the process overwhelming. There are many options available on the market. It’s easy to make mistakes when choosing. Researching and understanding specific requirements is key. Reflect on your project’s needs carefully. In the end, the right CNC end mill can enhance your machining outcomes, saving time and reducing waste.

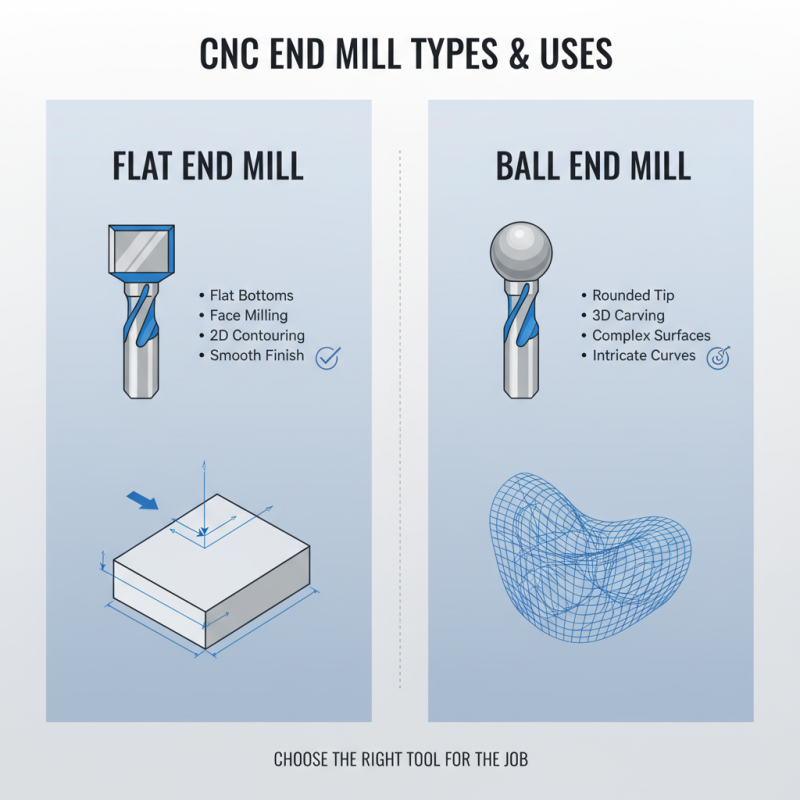

When selecting the right CNC end mill, understanding the types available is essential. There are various styles, each tailored for specific tasks. For example, flat end mills are perfect for face milling. They provide a smooth finish and are commonly used for 2D contouring. Ball end mills, on the other hand, excel in 3D work. They create intricate curves and complex surfaces.

Tips: Analyze the material you will be working with. Softer materials like plastic require different end mills than harder materials like steel. Choosing the right geometry matters. A high helix angle can improve cutting efficiency but might not be suitable for all projects.

Another key type is the tapered end mill. This design allows for deep cuts and angles, useful for intricate designs. The coated end mills offer longevity and heat resistance. However, some coatings may affect performance with specific materials. Remember, testing a few options can help refine your selection process. It’s often about finding balance, testing, and learning from your results.

Choosing the right CNC end mill starts with understanding material compatibility. Different materials demand specific tools for efficient machining. For instance, soft materials like aluminum require end mills with sharp edges for cleaner cuts. In contrast, tougher materials, such as hardened steel, benefit from stronger, more durable tools.

Consider the material thickness and density as well. This affects the depth of cut and feed rates. A mismatched end mill might cause excessive wear. It may also lead to poor finishes. Testing with a few different tools could help determine the best fit. However, this trial-and-error process can be time-consuming and frustrating.

Always observe how the end mill performs with each material. Adjustments might be necessary as you learn. Keeping records of successful and unsuccessful attempts can guide future projects. Reflection on these experiences can sharpen your selection process. This kind of evaluation is essential for long-term success. Stay curious and keep experimenting.

Choosing the right end mill geometry is essential for achieving the best results in CNC machining. Different projects require different shapes and sizes of end mills. For instance, a flat end mill works well for general purpose cutting. In contrast, a ball end mill is ideal for contouring shapes. Understanding your project needs helps narrow down the options.

When considering geometry, think about flute design. Open flutes often provide better chip removal, which can be crucial for deep cuts. Closed flutes may be preferred for finer finishes. The number of flutes is also significant. More flutes can increase efficiency in certain materials but may sacrifice chip clearance. Testing can reveal what works best, as assumptions can lead to mistakes.

Another detail to consider is the end mill diameter. A larger diameter may offer stability but can limit access to intricate designs. Smaller diameters allow for precision but can wear out quickly in tough materials. It's essential to reflect on your project requirements and potential challenges. This deliberation often leads to valuable insights for future machining tasks.

Choosing the right CNC end mill for your project involves understanding the cutting conditions. These conditions significantly impact the performance and lifespan of the end mill. Factors such as material type, feed rate, and spindle speed must be assessed thoroughly. For instance, cutting aluminum requires different parameters than cutting steel. According to a study, using improper conditions can reduce tool life by nearly 50%.

Tips: Start by analyzing the material you plan to cut. Each material has its unique properties and optimal cutting settings.

The geometry of the end mill plays a crucial role as well. The number of flutes affects chip removal and surface finish. A two-flute end mill is ideal for softer materials, while a four-flute version suits harder materials. Proper cooling lubrication also influences cutting efficiency. Inadequate cooling can lead to overheating and premature tool wear.

Tips: Always monitor your spindle speed. Too high a speed may cause chipping on harder materials.

By closely evaluating these cutting conditions, you can make better decisions about which end mill will suit your specific project. Remember, trial and error is part of the process. Not every choice will yield the expected results, so keep experimenting.

| End Mill Type | Material Compatibility | Number of Flutes | Coating | Recommended Cutting Speed (RPM) | Feed Rate (in/min) |

|---|---|---|---|---|---|

| Flat End Mill | Aluminum, Soft Plastics | 2-4 | None | 8000-10000 | 10-20 |

| Ball End Mill | Aluminum, Brass, Steel | 2-4 | TiN Coating | 6000-8000 | 8-15 |

| Diamond Coated End Mill | Composite Materials | 2-6 | Diamond Coating | 10000-12000 | 5-10 |

| Roughing End Mill | Steel, Aluminum | 4-6 | ZrN Coating | 5000-7000 | 15-25 |

| Tapered End Mill | Plastic, Wood | 2-4 | TiAlN Coating | 6000-9000 | 10-18 |

When choosing CNC end mills, budget is a key factor. You want quality tools without overspending. Researching various options is essential. Prices can vary significantly, but so can the quality. A low price might attract you, but does it mean lesser performance?

Consider the material you will be cutting. For softer materials, a basic end mill may suffice. For harder materials, investing in better quality tools might be necessary. This decision can make or break your project. It’s crucial to find a balance.

Don’t forget to check reviews and user experiences. Sometimes, inexpensive tools can lead to frustrating results. A part might not cut cleanly. In those moments, reconsidering your choices is vital. Budget constraints are common; however, not all affordable options are worth it. Take time to analyze and reflect on the tools you choose. You want to avoid unnecessary setbacks in your project.