- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Choosing the right Correa CNC machine can be a daunting task for many businesses. Expert John Smith, a renowned specialist in CNC technology, asserts, “Investing in the right machine changes everything.” When selecting a Correa CNC, understanding your specific needs is crucial. These machines offer a range of capabilities, from precise milling to complex machining.

Consider your production volume and types of materials. Correa CNC machines excel in industries like aerospace and automotive. However, not all models fit every purpose. It’s essential to assess what features matter most, such as speed, precision, and versatility. The wrong choice can lead to inefficiency, impacting quality and profitability.

Additionally, think about your workspace and budget. A larger, more advanced model may be tempting but could stretch your resources too thin. While Correa CNC machines are highly regarded, they require careful consideration. Analyze your long-term goals and seek advice before making a decision. The right Correa CNC can significantly enhance your operations if chosen wisely.

When selecting a Correa CNC machine, understanding the various types available is essential. These machines vary significantly in capabilities and applications. One common type is the bed type machine, known for its stability. It's ideal for larger, heavy parts. However, its size can be a limitation for small workshops. Many businesses overlook this aspect, leading to inefficient production.

Another popular choice is the gantry type CNC machine. This type provides large workspace flexibility. It’s suitable for complex parts requiring high precision. But the initial investment can be high, causing hesitation for many small companies. Their space requirements also pose challenges. It’s crucial for businesses to evaluate their floor plans.

Vertical CNC machines are also widely asked for. These machines are versatile and can handle diverse tasks. They work well for quick setups and smaller batches. However, their capabilities may not meet heavy-duty requirements. Companies often find themselves needing more. Understanding these distinctions helps businesses make informed decisions, aligning their machine selection with production needs.

When selecting a CNC machine, understanding your business requirements is crucial. Consider the types of materials you’ll work with. Various machines handle different materials. Analyzing your production goals helps you determine the machine's capabilities. For instance, if your focus is on high-speed production, you may need a machine designed for that specific need.

Evaluate your current operational capacity. Are you meeting client demands with your current setup? If not, consider investing in an advanced model. However, budget constraints often complicate decisions. It’s vital to balance performance and cost. Reflect on whether a more expensive machine justifies its value regarding increased efficiency or reduced waste.

Think about scalability too. As your business grows, can the machine adapt? A solution that fits now may not fit later. Consult with your team. Their insights might reveal hidden needs. Engaging with staff can lead to unexpected reflections on production processes. This collaboration is essential for making a well-informed choice.

When selecting a CNC machine, evaluating key features is crucial. Start by looking at the machine's size and capacity. Larger materials require machines with broader workspaces. A compact model might save space, but it limits your project size. Always consider your specific needs.

Consider the types of materials you'll work with. Some machines handle metals well, while others are better for plastics or wood. Compatibility with your materials is essential. For instance, working with composites may require a higher spindle speed.

Tips: Always check the power consumption. A machine that seems efficient may cost more in the long run. Assess the precision and tolerance levels. Machines can differ greatly. Ask about maintenance requirements. Keeping a machine running smoothly can save costs.

Don't overlook software capabilities. User-friendly software can make a significant difference. Your workflow might suffer with complicated systems.

Tips: Take advantage of online forums to learn from other users. They often share insights that you won't get from the manufacturer. An informed decision is often the best one.

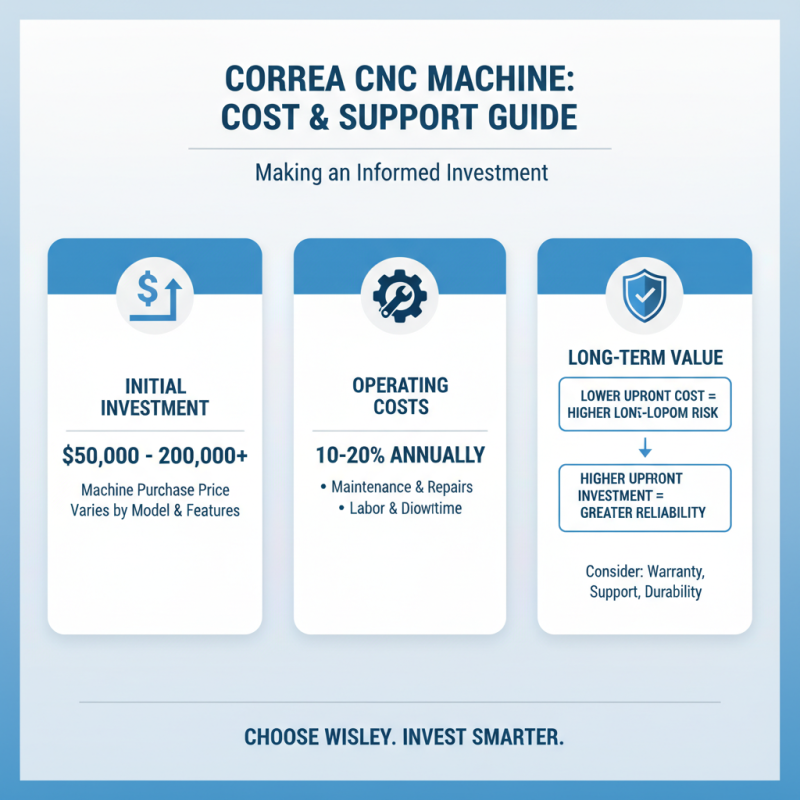

When choosing a Correa CNC machine, understanding costs and support options is critical. According to industry reports, CNC machines can range from $50,000 to over $200,000. Maintenance costs often add 10-20% annually to the total cost. Less expensive machines might save you upfront but could incur higher long-term expenses due to frequent repairs.

Support services can vary widely. Many manufacturers offer different tiers of support, from basic to comprehensive. A recent survey showed that 40% of business owners regretted opting for machines with limited support. This often leads to extended downtime and lost revenue. It’s essential to evaluate the availability of spare parts and expertise nearby. Having local support can drastically reduce maintenance lead times.

Consider the machine's reliability based on your production needs. Some machines may deliver accuracy but require frequent calibrations. This can affect productivity. Reflect on your team’s skills too; a complex machine may need advanced training. Balancing cost, maintenance, and support is challenging. But, making a well-informed choice can enhance performance in the long run.

Selecting the right CNC machine for your business needs can be daunting. With numerous options available, you might feel overwhelmed. Industry reports indicate that around 70% of businesses report challenges in choosing the right machine. This decision affects productivity and overall efficiency.

Tip: Identify your specific needs. Assess the materials you will be machining and the complexity of the projects. Not all machines can handle every task. For example, intricate designs require a more versatile CNC machine. Researching these specs can save you time and money in the long run.

Some businesses opt for the cheapest option without considering long-term implications. This choice can lead to frequent breakdowns, costing more in repairs. A survey found that companies investing in quality machines typically see an increase in production rates by 30%. Balancing budget constraints with quality is crucial.

Tip: Look for customer reviews and case studies. They often reveal insights into performance and reliability that specifications do not cover. Conducting this research can avoid costly mistakes. It’s essential to reflect on all aspects before making a decision.

| Dimension | Specification | Application | Price Range | Suitable Industries |

|---|---|---|---|---|

| Compact | Axis: 3, Table Size: 800x500 mm | Prototype Testing | $20,000 - $30,000 | Manufacturing, Aerospace |

| Standard | Axis: 4, Table Size: 1200x800 mm | Small Batch Production | $40,000 - $60,000 | Automotive, Electronics |

| Large | Axis: 5, Table Size: 2000x1200 mm | Mass Production | $80,000 - $120,000 | Heavy Industries, Tooling |

| Specialized | Custom Configurations Available | High Precision Parts | $100,000+ | Medical, Aerospace |