- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

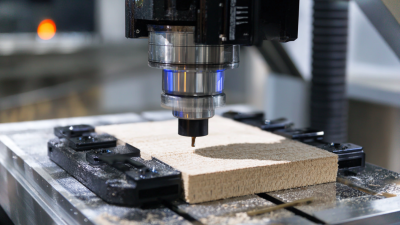

In the realm of precision machining, the selection of the right CNC clamp is pivotal to achieving optimal results in any project. According to industry expert John Smith, a noted authority on CNC machining, “Choosing the right CNC clamp not only enhances the accuracy of your work but also significantly improves overall efficiency.” With a myriad of options available, understanding the specific needs of your machining projects is essential for making an informed choice.

CNC clamps come in various designs and materials, each tailored for distinct applications in the machining process. Factors such as workpiece size, type of material, and the machining operation itself play crucial roles in determining which CNC clamp will provide the best support and stability. An experienced machinist must consider these variables to ensure that the selected clamp aligns with their project requirements and contributes to achieving precise results.

As we delve deeper into this topic, we will explore the key considerations and features that can guide you in making the right decision regarding CNC clamps. From adjustable designs to material strengths, understanding these aspects can lead to enhanced performance and productivity in your machining projects.

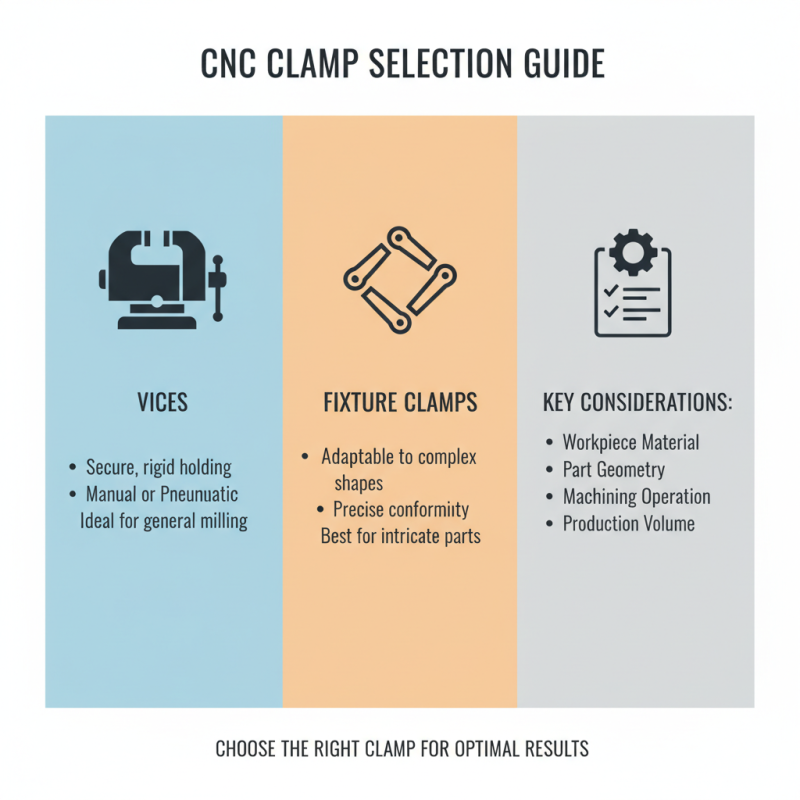

When selecting a CNC clamp for your machining projects, it's essential to understand the various types available and their respective applications. Vices are commonly used in CNC machining to hold workpieces securely during milling operations. They come in different sizes and styles, such as manual or pneumatic vices, each suited for specific tasks. For intricate parts, fixture clamps, which are adaptable and can accommodate varying shapes and sizes, are an excellent choice due to their ability to provide precise conformity to the workpiece geometry.

Another popular type of clamp in CNC applications is the T-slot clamp, which offers versatility in positioning. These clamps allow for quick adjustments and can be easily mounted on a T-slot table, making them perfect for prototype work. Additionally, step clamps are utilized for securing parts with irregular shapes or heights. Their unique design allows them to hold the workpiece firmly while providing room for cutting tools.

Tips: Always consider the material and weight of your workpiece when selecting a clamp; heavier materials may require more robust clamps for stability. Additionally, ensuring that the clamp does not interfere with the cutting path is crucial for achieving optimal machining results. Regular maintenance and inspection of your clamps can also prevent potential issues and enhance the longevity of your machining setup.

When selecting the right CNC clamp for your machining projects, several key factors should be taken into account. Firstly, consider the material of the clamp. Clamps made from durable materials such as steel or aluminum can withstand high pressures and provide better stability during the machining process. Additionally, the material impacts the weight and handling of the clamp, which can influence setup time and overall productivity.

Another critical aspect is the size and type of the clamp. It's essential to ensure that the clamp not only fits the workpiece securely but also accommodates the specific machining operations you plan to conduct. Different types of CNC clamps, such as toggle clamps or pneumatic clamps, offer varying degrees of holding power and ease of use. Therefore, evaluating the specific requirements of your project, including the dimensions and shape of the workpiece, can greatly affect the efficiency and accuracy of the machining process.

When selecting CNC clamps, the material choice plays a critical role in their performance and suitability for various machining projects. Common materials include aluminum, steel, and plastic, each with distinct advantages and drawbacks. Aluminum clamps are lightweight and offer good corrosion resistance, making them a popular choice for applications that require mobility. They are also less abrasive on workpieces, which can be advantageous in precision machining. However, aluminum may lack the rigidity required for heavy-duty applications, leading to potential deformation under extreme pressure.

On the other hand, steel clamps offer superior strength and durability, making them ideal for heavy machining tasks. They can withstand significant forces without bending or breaking, providing reliable support for demanding projects. However, their weight can be a downside in situations where lighter equipment is preferred. Additionally, steel clamps are more susceptible to rust, necessitating protective coatings or careful maintenance to prevent corrosion. For lighter applications or prototyping, plastic clamps can be an effective option, as they are resistant to chemicals and very lightweight, but they typically do not provide the mechanical strength required for heavier machining activities. Ultimately, the right material for your CNC clamps will depend on your specific project requirements and the balance between weight, strength, and durability you need.

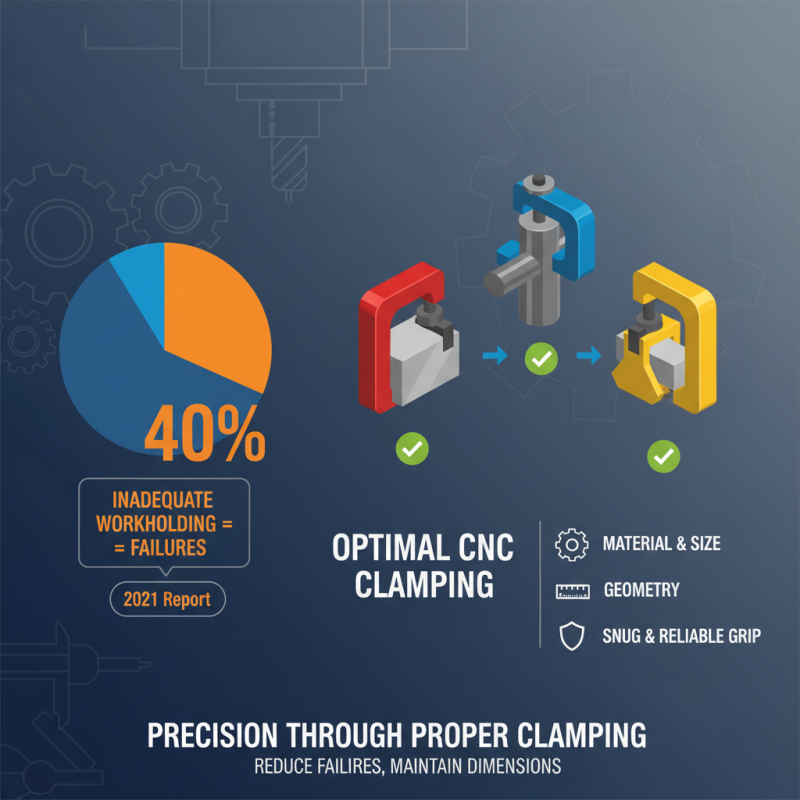

When embarking on machining projects, ensuring the proper fit and stability of CNC clamps is crucial to achieving optimal results. According to the 2021 CNC Machining Market Analysis Report, nearly 40% of precision machining failures are attributed to inadequate workholding methods, underscoring the importance of selecting the right clamps. Properly fitting clamps not only secure various workpieces but also help in maintaining the integrity of dimensions during the machining process. It is essential to assess the specific characteristics of the workpiece, including its material composition, size, and geometry, in order to choose clamps that provide a snug and reliable grip.

In addition to fit, stability is another key factor that significantly influences the machining accuracy. Research shows that vibrations during machining can lead to poor surface finishes and dimensional inaccuracies, with some studies estimating that vibration can increase error margins by up to 10%. Utilizing CNC clamps designed with anti-vibration features or those made from materials like carbon fiber or aluminum can help mitigate these issues. Furthermore, implementing a pre-tensioning strategy to eliminate play between the clamp and the workpiece can remarkably enhance stability, allowing for tighter tolerances and better repeatability in production runs.

When it comes to CNC machining, the efficiency of your setup largely depends on how well your CNC clamp is installed. Proper installation techniques ensure stability during the machining process and reduce the likelihood of errors. One essential practice is to ensure that the clamp is securely fastened to the work surface. This can be achieved by utilizing appropriate fastening methods such as screws or bolts that can withstand the machining forces. Furthermore, aligning the clamp accurately with the workpiece is crucial to achieve precise cuts and prevent tool wear.

Another effective installation technique involves the use of support structures to enhance clamp stability. By placing additional bracing or using adjustable supports, you can reduce vibrations that may occur during machining. It is also important to regularly check the condition of the clamps and their installation, as wear or misalignment over time can impact machining performance. Incorporating routine inspections and adjustments into your workflow can help maintain maximum efficiency and lead to higher quality outcomes in your CNC machining projects.

| Clamp Type | Material | Clamping Force (lbs) | Weight (lbs) | Adjustment Mechanism | Price Range ($) |

|---|---|---|---|---|---|

| C-Clamp | Steel | 1500 | 4.5 | Screw | 10-20 |

| Toggle Clamp | Aluminum | 1200 | 2.0 | Toggle | 15-25 |

| Pneumatic Clamp | Steel | 2000 | 5.0 | Pneumatic | 50-100 |

| Vacuum Clamp | Plastic | 800 | 3.0 | Vacuum | 30-60 |

| Hydraulic Clamp | Steel | 2500 | 6.5 | Hydraulic | 100-200 |