- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In today’s competitive manufacturing landscape, businesses are turning to CNC machines for precision and efficiency. According to a report by Smith Market Research, the CNC machine market is projected to grow by over 6% annually through 2025. This growth reflects a shift towards automation and accuracy in production processes. CNC machines are designed to enhance productivity while minimizing errors, which is crucial for meeting customer demands.

Workers can operate CNC machines with less manual intervention, allowing them to focus on complex tasks. However, it is essential to recognize that transitioning to CNC technology requires an initial investment and upskilling of staff. A survey from Advanced Manufacturing Technology found that 40% of manufacturers cite training as a significant barrier to CNC adoption.

Despite challenges, CNC machines offer considerable advantages. They are capable of producing intricate parts and maintaining high repeatability. Nonetheless, manufacturers must frequently evaluate their current workflows to maximize the benefits of CNC technology. It’s vital to reflect on how these machines can fit into broader operational strategies while addressing potential limitations.

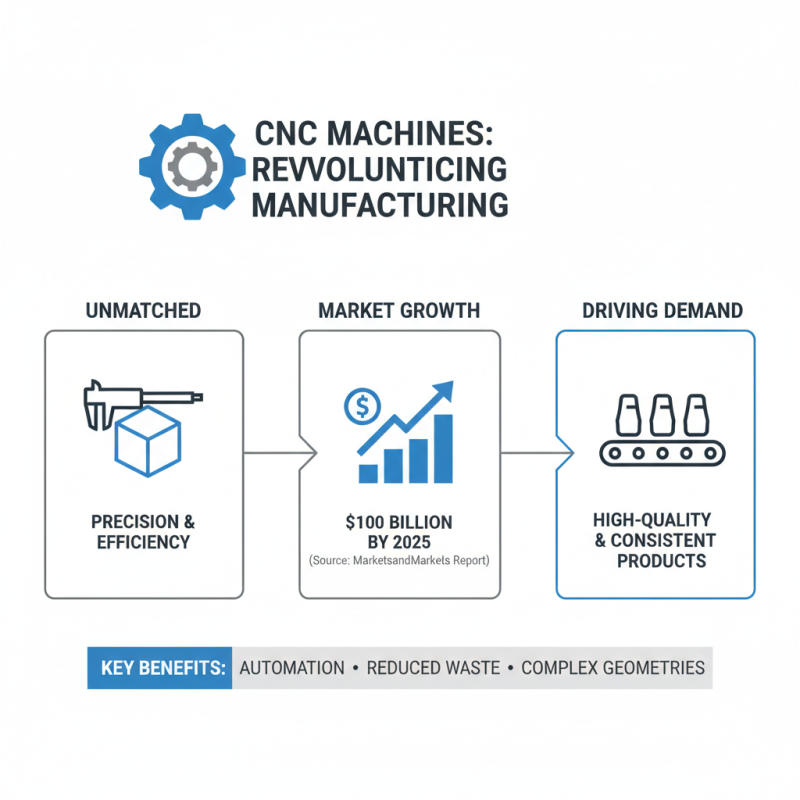

CNC machines are transforming the manufacturing industry. Their precision and efficiency are unmatched. According to a report by MarketsandMarkets, the CNC machine market is expected to reach $100 billion by 2025. This growth is driven by the increasing demand for high-quality and consistent products.

One major benefit of using CNC machines is reduced human error. CNC systems rely on computer programming, which minimizes mistakes often caused by manual operations. However, operators must still be well-trained. Poor programming can lead to significant issues. It’s essential to regularly review and update programming techniques.

Tip: Invest in regular training for your team. Continuous learning helps to avoid operational errors.

Moreover, CNC machines can produce complex parts with ease. This capability leads to greater design freedom. However, the initial investment can be daunting for some businesses. Yet, the long-term savings in labor and material can outweigh these costs. Companies can often see a return on investment in a few years.

Tip: Evaluate your production volume. High-volume jobs may benefit most from CNC technology.

CNC machines are transforming manufacturing efficiency. They offer precision and speed that traditional methods struggle to match. According to a recent report by the National Association of Manufacturers, CNC machines can reduce production time by up to 30%. This efficiency is vital in meeting growing customer demands.

One key feature of CNC technology is automation. Automation decreases human error, leading to higher quality outputs. In fact, manufacturers using CNC can achieve up to 50% more consistent results. However, operators need training to manage these machines effectively, which can sometimes lead to initial production slowdowns.

Another significant aspect is the capability for complex designs. CNC machines can create intricate patterns that would be impossible manually. This flexibility allows for innovation but demands a careful balance of design and feasibility. As the manufacturing landscape evolves, understanding these features is essential for staying competitive.

| Feature | Description | Benefits | Application |

|---|---|---|---|

| Precision | CNC machines are designed to perform tasks with high accuracy and repeatability. | Reduces waste and improves product quality. | Aerospace, automotive components. |

| Automation | Automated control allows for continuous operation without frequent human intervention. | Enhances efficiency and reduces labor costs. | Mass production, high-volume manufacturing. |

| Flexibility | CNC machines can be programmed for various tasks and designs. | Allows for quick changes in production to meet market demands. | Custom parts manufacturing, prototyping. |

| Speed | CNC machines operate faster than manual machining processes. | Increases throughput and reduces lead times. | High-volume production environments. |

| Cost-effectiveness | Lower production costs due to efficiency and reduced material waste. | Improves overall profit margins. | Small to large manufacturers. |

CNC machines have become a cornerstone in modern manufacturing. They offer precision and consistency that traditional methods often lack. With ordinary machines, manual input can introduce errors. A slight miscalculation can lead to waste, time delays, and increased costs. CNC machines eliminate much of that risk. They operate based on computer-generated designs. This means higher accuracy in every cut or mold.

However, CNC technology isn’t perfect. Initial setup can be time-consuming. Programming can seem daunting, especially for complex projects. Operators need training to navigate software effectively. Traditional methods, on the other hand, might require fewer technical skills. Craftsmen can rely on years of experience. Yet, they can struggle to replicate identical results. This inconsistency is a drawback for businesses focused on high volume.

In terms of versatility, CNC machines shine. They can switch between tasks without major adjustments. Traditional equipment often requires numerous tools for different jobs. This can lead to increased downtime and less efficiency. Still, relying solely on CNC can be limiting. Not all designs are suited for computer-aided processes. There’s a need for balance between innovation and craftsmanship. Finding that sweet spot can enhance overall productivity.

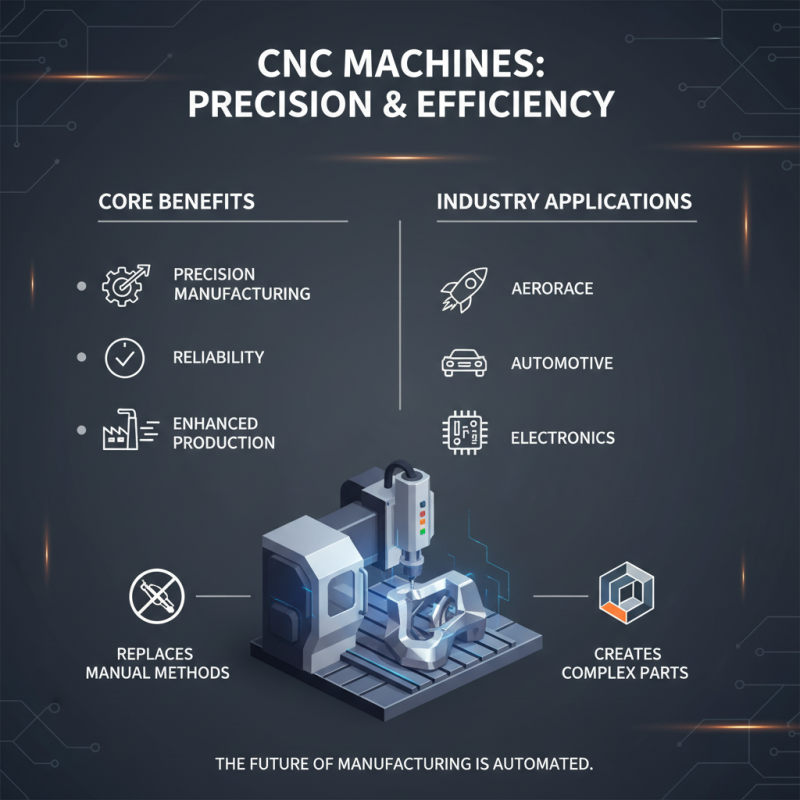

CNC machines have become essential in various industries. They offer precision and reliability in manufacturing processes. From aerospace to automotive, CNC machines enhance production efficiency. They can create complex parts that are often difficult or impossible to achieve with manual methods.

In the automotive sector, CNC technology is used for making engine components and body parts. These machines ensure that every piece fits perfectly. In the aerospace industry, they produce intricate elements for aircraft. The level of detail required in this field is critical. Errors can be costly and dangerous.

Tips: When considering CNC machines, think about the specific requirements of your projects. You may need to adjust your designs for maximum efficiency. Regular maintenance is key. It keeps the machines working optimally and reduces downtime.

CNC machines also find their place in the medical field. They create custom implants and instruments with high precision. The ability to adapt designs for different patients is a significant advantage. Yet, the learning curve can be steep. It's important to invest time in understanding how to operate them effectively.

Choosing a CNC machine is a significant decision for any manufacturing business. The right machine can streamline production and enhance efficiency. However, it’s essential to consider several factors before making a purchase. One key factor is the material you will be working with. Different machines handle various materials differently, impacting the final product's quality.

Another important element is the machine’s size and complexity. Ensure the CNC machine fits within your workspace. A larger machine may require more maintenance and training. Moreover, consider your production volume. High-volume tasks often need machines with faster cycle times. Evaluate the software compatibility as well. Some systems may not easily integrate with your existing workflow, causing disruptions.

Budget is always a concern. Initial costs can be steep, but factor in long-term expenses. Maintenance, repairs, and upgrades add to the overall investment. The learning curve can also be a challenge. Employees may need training to operate a new machine effectively. These reflections are crucial, as choosing the wrong CNC machine can lead to wasted resources and reduced productivity.