- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Choosing the right Piese Cnc for your machining needs is a crucial step that can significantly impact your production efficiency and the quality of your finished products. With a plethora of options available in the market, understanding the specific requirements of your machining tasks becomes essential. Whether you are involved in precision engineering, prototyping, or large-scale manufacturing, selecting the appropriate Piese Cnc will determine not only the effectiveness of your operations but also the overall success of your projects.

In this guide, we will explore the key factors to consider when choosing Piese Cnc, focusing on aspects such as material compatibility, machine specifications, and the intended applications. By clearly assessing your machining requirements, you can better navigate the options and invest in a solution that aligns with your production goals. We will also look into how features like precision, speed, and user-friendliness play a role in enhancing your manufacturing capabilities. Ultimately, with the right Piese Cnc, your machining process can be optimized to achieve higher efficiency and quality output.

When considering CNC (Computer Numerical Control) machines for your machining applications, it's essential to understand their fundamental principles and functionalities. CNC machines utilize computer software to control the movement of machinery tools, allowing for high precision and automation in production processes. The core components of CNC machines include the controller, drive system, and the tool itself. Understanding how these elements work together can help you select the appropriate machine type for your specific tasks, whether it’s milling, turning, or routing.

Another crucial aspect to consider is the material you will be working with and the complexity of the designs you wish to create. Different CNC machines are optimized for various materials, such as metals, plastics, or wood. Additionally, specific applications may require different machining processes. For example, more complex designs might benefit from a multi-axis CNC machine, which can move along multiple planes. By evaluating the nature of your projects and the required precision, you can make a more informed decision, ensuring that your chosen CNC machine aligns perfectly with your machining needs.

Identifying your specific machining needs is a critical step in selecting the right CNC machine. The machining industry has witnessed a significant shift towards automation and precision, with a recent report from the Association for Manufacturing Technology indicating that over 70% of manufacturers prioritize accuracy and repeatability in their machining processes. This highlights the importance of understanding your unique application requirements, such as part complexity, material types, and production volume. For instance, choosing a CNC machine with multi-axis capabilities may be essential for companies focusing on intricate geometries or complex tooling applications.

Moreover, evaluating your operational efficiencies can guide your decision-making. According to a study by Deloitte, nearly 60% of manufacturers are implementing smart factory technologies to improve their overall equipment effectiveness (OEE). Factors such as cycle time, setup time, and machine utilization should be meticulously analyzed. By assessing these elements, you can determine whether a high-speed machining center or a more versatile CNC lathe better suits your production needs. Ultimately, a thorough assessment of your machining requirements leads to a more informed choice, optimizing both efficiency and cost-effectiveness in your manufacturing operations.

When evaluating different CNC machine types and their features, it is essential to first understand the specific requirements of your machining projects. CNC machines can vary significantly in terms of functionality, precision, and intended applications. For instance, a CNC mill is ideal for creating complex shapes and contours, while a CNC lathe excels in producing cylindrical parts with high accuracy. Assessing the types of materials you will be working with—such as metals, plastics, or wood—is crucial, as some machines perform better on certain materials than others.

Additionally, closely examining the features of various CNC machines can help in making an informed decision. Look for machines that offer versatility and can be easily adapted for different tasks. Features like high spindle speeds, multi-axis capabilities, and advanced software compatibility can enhance productivity and the quality of finished products. Furthermore, consider the scale of your operations; smaller machines may suffice for hobbyists or small businesses, while larger, industrial-grade machines might be necessary for high-volume production. By carefully evaluating these aspects, you can choose the right CNC machine that aligns with your machining needs.

| CNC Machine Type | Best For | Key Features | Price Range |

|---|---|---|---|

| Router CNC | Woodworking, Sign Making | High-speed cutting, Variable speed control, Easy to use | $2,000 - $10,000 |

| Laser CNC | Engraving, Cutting Materials | Precision cutting, Easy operation, Versatile material compatibility | $3,000 - $15,000 |

| Plasma CNC | Metal Fabrication | Fast cutting speeds, Thick material handling, Portable options available | $5,000 - $25,000 |

| Milling CNC | Precision Parts, Aerospace | Multi-axis machining, High accuracy, Versatile tool options | $10,000 - $75,000 |

| 3D CNC Printer | Prototyping, Small batch production | Additive manufacturing, Wide material options, Minimal waste | $1,500 - $20,000 |

Choosing the right CNC machine involves several critical considerations, particularly concerning material compatibility and processing capabilities. According to a report from the International Association of CNC Machinists, over 50% of machining errors arise from mismatched material and processing setups. This highlights the importance of understanding the specifications of the materials you intend to work with. For example, metals like aluminum and titanium require different spindle speeds and tooling options due to their distinct properties. Aluminum is more forgiving and can often be machined at higher speeds, while titanium demands lower speeds and specialized tooling to prevent heat buildup and tool wear.

In addition, the processing capabilities of a CNC machine should align with the desired outcomes of your projects. Research by the Manufacturing Technology Society indicates that machining efficiency can improve by 30% when the correct CNC machine is paired with compatible materials. Additionally, advanced CNC machines now offer features such as adaptive machining and real-time feedback systems, which adjust processing parameters on-the-fly according to the material behavior. This adaptability can significantly enhance both precision and productivity, making it essential to select a CNC machine that supports these features while being compatible with your specific materials. Thus, thorough assessment of both material properties and machine capabilities is crucial for achieving optimal machining results.

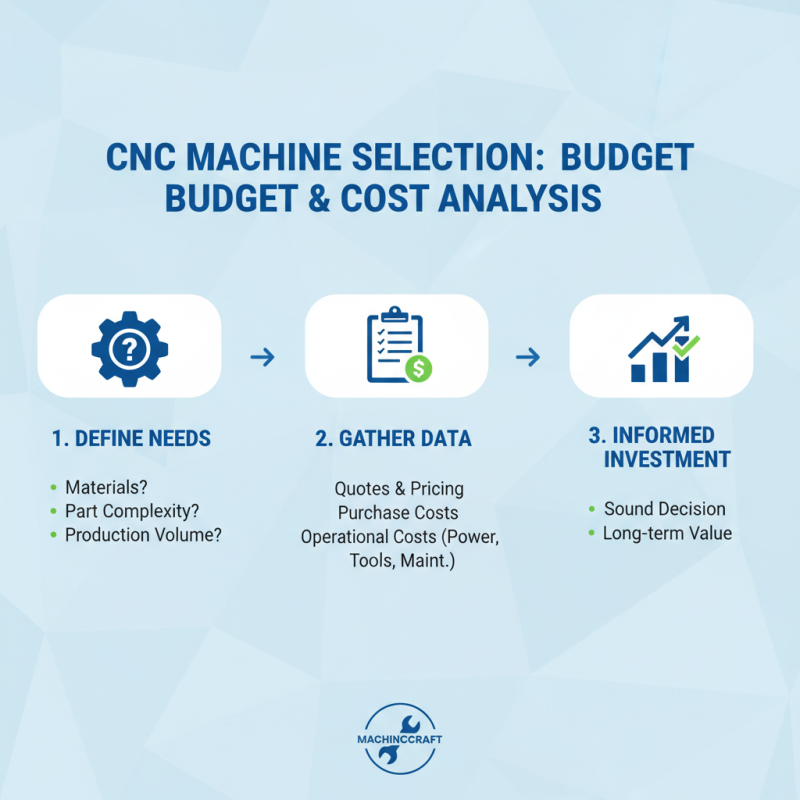

When selecting a CNC machine, budgeting and cost analysis play crucial roles in ensuring a sound investment. The first step is to establish a clear understanding of your machining needs, which will help you determine the necessary specifications of the CNC machine. Consider factors such as the materials you'll be working with, the complexity of the parts you need to produce, and the expected production volume. Once you have this framework, you can start to gather quotes and pricing information for different machines, making note of both initial purchase costs and ongoing operational expenses.

It's also important to analyze the long-term costs associated with your CNC investment. This includes maintenance, tooling, and software updates, which can significantly impact your overall budget. Additionally, consider potential training costs for your operators, as well as any adaptations needed to integrate the CNC machine into your existing processes. By evaluating these aspects carefully, you can develop a comprehensive cost analysis that not only reflects the purchase price but also provides insight into what you can expect in terms of return on investment over time.