- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

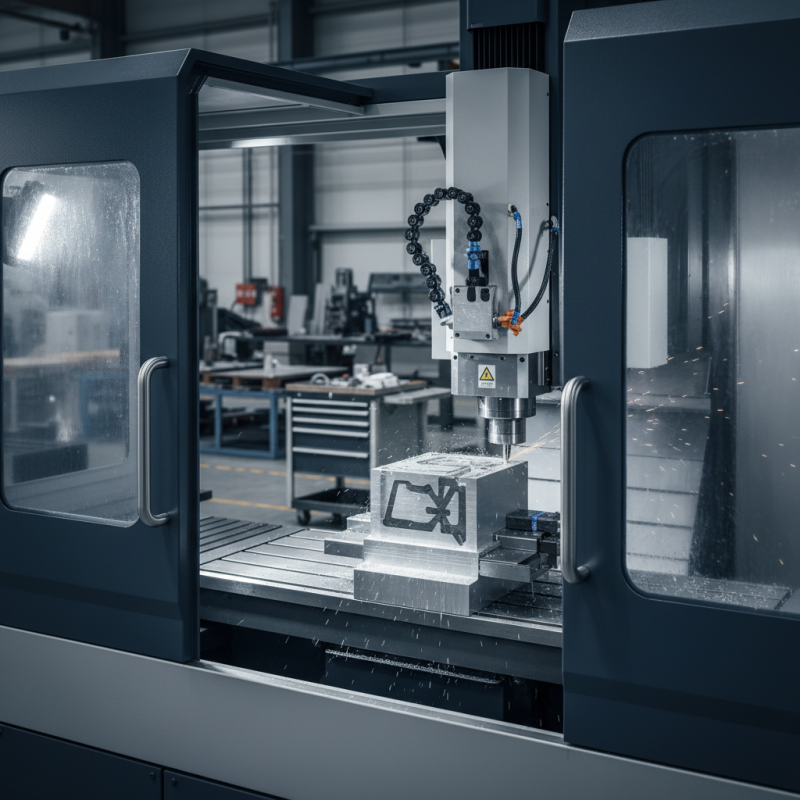

In the ever-evolving world of manufacturing, selecting the right metal CNC machine can be a daunting task for both seasoned professionals and newcomers alike. With the advancements in technology, a wide array of machines offers different functionalities and specifications tailored to various project needs. As Tom Edwards, a leading expert in the Metal CNC industry, wisely stated, “The success of your project hinges on the precision and reliability of the machine you choose.” This insight underscores the importance of making informed decisions when it comes to investing in CNC technology.

When navigating through the multitude of options, it is essential to consider factors such as the type of metal to be processed, the complexity of the designs, and the production volume. Different CNC machines are suited for different applications; hence, understanding your specific project requirements can guide you toward the best choice. Whether it's producing intricate components for aerospace or simple brackets for furniture, the right Metal CNC machine will significantly enhance efficiency and quality.

Ultimately, choosing the best Metal CNC machine is not merely about selecting the most advanced model; it is about aligning the machine's capabilities with your unique project needs. With careful consideration and a clear understanding of the essential features, you can ensure that you make a decision that propels your project forward with precision and excellence.

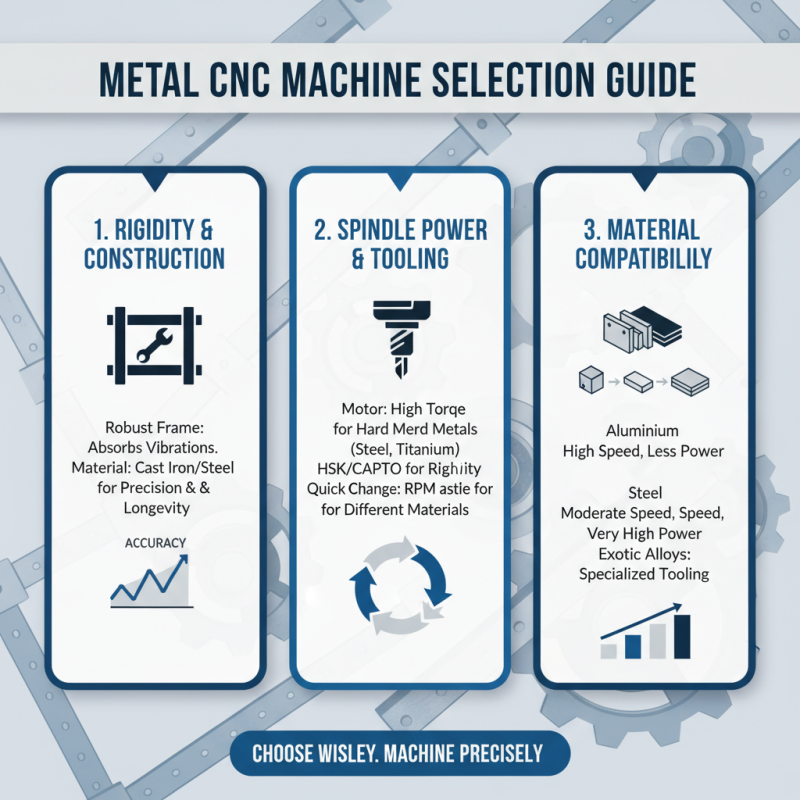

When selecting the best metal CNC machine for your project, understanding your specific requirements is crucial. Begin by assessing the types of materials you will be working with, as different CNC machines handle different metals with varying levels of efficiency. For instance, if your project involves soft metals like aluminum, you may require a machine with high-speed capabilities, while harder materials like titanium necessitate more robust and powerful machines.

Tips: Consider the tolerance and precision needed for your end product. Projects requiring intricate details or tight tolerances will demand higher quality machining capabilities. Investing in a machine that offers advanced technological features such as multi-axis operation can significantly enhance both the speed and precision of your work.

Additionally, think about the scale of your projects. Will you be producing small batches or large-scale runs? Machines that are ideal for one-off prototypes may not be suitable for high-volume production. Evaluate features like the machine’s speed, ease of use, and maintenance requirements to ensure that it aligns with your operational workflow. Prioritizing these factors will help you choose a metal CNC machine that meets and exceeds your project demands.

When selecting a metal CNC machine, several key features must be taken into account to ensure it meets your project needs. Firstly, the machine's rigidity and construction material are crucial for precision and longevity. A robust frame can absorb vibrations, leading to better accuracy in machining processes. Additionally, consider the type of metal you will be working with, as this influences the need for more powerful spindle motors or specific tool holders designed for materials like aluminum, steel, or titanium.

Another critical feature to evaluate is the machine's software compatibility and user interface. An intuitive interface allows for easier operation and minimizes the learning curve, particularly important for those new to CNC machining. Furthermore, look into the machine's tooling options and the range of compatible tools. This will ensure versatility in your projects, allowing for a variety of machining operations, such as milling, drilling, or engraving. Lastly, evaluate the machine's maintenance requirements and support services to ensure reliable long-term performance and minimize downtime.

When selecting a metal CNC machine, understanding the various types available and their specific applications is crucial. There are several categories of metal CNC machines, including CNC milling machines, CNC lathes, and CNC plasma cutters. According to a recent industry report, the CNC milling machine market alone is projected to grow at a CAGR of 6.76% from 2021 to 2026, highlighting the increasing demand for precision machining in manufacturing sectors. CNC milling machines are ideal for creating complex parts with intricate designs, making them suitable for the aerospace and automotive industries.

CNC lathes, on the other hand, are perfect for producing cylindrical parts and are frequently used in the manufacturing of shafts, fittings, and other parts with rotational symmetry. A study from MarketsandMarkets suggests the CNC lathe market will reach USD 2.1 billion by 2026. This type of machine provides high precision and efficiency, which are essential in sectors like medical device manufacturing and custom machinery production.

**Tips**: When choosing a CNC machine, consider the material you will primarily work with. For thicker metals, a CNC plasma cutter may offer faster processing times, while machining aluminum and softer alloys may benefit from a CNC milling machine. Additionally, evaluate the intricacy of the components you need to produce; complex geometries often require a more versatile CNC machine capable of multi-axis operations for best results.

| Machine Type | Description | Applications | Material Compatibility |

|---|---|---|---|

| CNC Milling Machine | Utilizes rotating cutters to remove material from a stationary workpiece. | Machining complex parts, molds, and prototypes. | Aluminum, steel, titanium. |

| CNC Turning Machine | Rotates the workpiece against a stationary cutter to shape it. | Production of cylindrical parts, shafts, and fittings. | Brass, aluminum, steel. |

| CNC Plasma Cutter | Uses plasma to cut through conductive materials. | Metal fabrication, lettering, and artistic design. | Steel, stainless steel, aluminum. |

| CNC Laser Cutter | Uses laser technology to cut and engrave materials. | High-precision cuts, engraving, and etching. | Steel, stainless steel, acrylic. |

| CNC Waterjet Cutter | Uses a high-pressure stream of water or abrasive mixtures. | Cutting complex shapes without heat distortion. | Metal, glass, stone, ceramics. |

When considering a metal CNC machine for your project, budgeting and cost analysis are crucial steps in the decision-making process. First, identify the key factors that influence the overall cost, such as the machine's specifications, capabilities, and additional features. Higher-end machines may offer advanced functionalities like multi-axis machining and automated tool changes, which can significantly enhance productivity but also come at a higher price. Consider your specific project requirements to determine which features are essential and which can be sacrificed, ensuring that you stay within your budget without compromising on quality.

Next, take into account the long-term costs associated with owning a CNC machine. This includes maintenance expenses, replacement parts, and software updates. Additionally, factor in the initial training required for operators to efficiently use the machine, as skilled personnel may be necessary to maximize the machine's potential. By conducting a thorough cost analysis and predicting potential operational costs, you can create a more accurate budget. This foresight will not only help you select a suitable metal CNC machine but also enable you to assess its viability for your projects in the long run.

When selecting a metal CNC machine, evaluating brand reputation and customer support is crucial to ensuring a satisfactory purchase. Trusted brands often have a history of product quality and reliability, which can significantly reduce the likelihood of issues arising during operation. Researching customer reviews and third-party evaluations can provide insights into how well a brand stands up over time and the experiences of others who have used their machines. Brands that consistently receive positive feedback often have established a reputation for durability and precision, essential factors for any metalworking project.

In addition to brand reputation, effective customer support can greatly enhance the overall experience of using a CNC machine. A manufacturer that offers comprehensive support—such as training, troubleshooting assistance, and readily available spare parts—can make a significant difference in addressing any challenges that may arise. When assessing customer support, consider the availability of resources such as manuals, tutorials, and online assistance. Companies that prioritize customer service tend to foster a more positive relationship with their users, ultimately leading to a more successful operation of the CNC machine and a smoother workflow for your projects.