- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

The world of CNC machining is evolving rapidly. One key component that deserves attention is the CNC stopper. A reliable CNC stopper ensures precision and enhances overall productivity. These tools play a crucial role in maintaining accuracy during the machining process. In 2026, selecting the best CNC stoppers will impact efficiency on many manufacturing floors.

Many CNC operators are still unaware of how important CNC stoppers are. Their choice can make or break production quality. Some may underestimate the cost of poor performance. This outlook may lead to wasted resources and time. It’s vital to understand that investment in high-quality CNC stoppers pays off in the long run.

As we look toward 2026, a variety of options will flood the market. Some stoppers will promise precision but may fall short. It’s essential to research and evaluate the best choices. The most effective CNC stoppers are those that combine durability and accuracy. Manufacturers must remain mindful of these factors. The right choice will boost performance and minimize mistakes in the machining process.

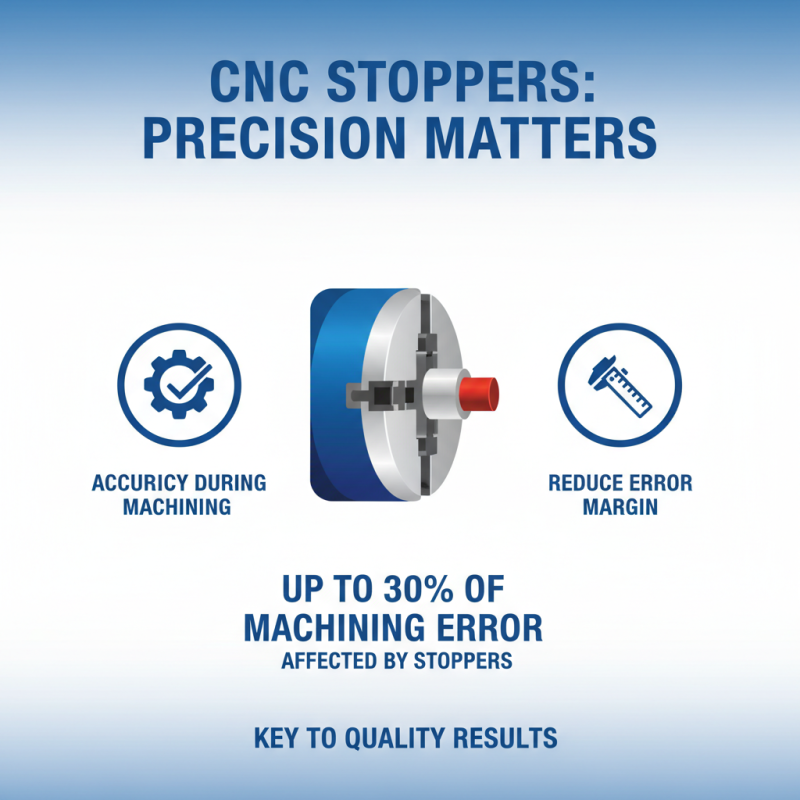

When selecting CNC stoppers, precision is paramount. Effective CNC stoppers ensure accuracy during machining processes. According to recent industry reports, stoppers can affect up to 30% of the machining error margin. This figure highlights their importance in achieving quality results.

Stability is one of the top characteristics to consider. CNC stoppers should possess a solid construction to minimize vibrations. Materials like aluminum or hardened steel are common choices. Additionally, ease of adjustment is crucial. Operators need tools that allow quick changes for efficiency. A 2023 survey revealed that 65% of machinists prefer stoppers that offer easy recalibration. However, some may overlook maintenance. Regular checks can prevent unexpected shifts in precision.

Another vital feature is compatibility with various machines. Not all stoppers fit every CNC model. A mismatch can lead to wasted time and resources. Reports show that 42% of users had faced issues due to improper sizing. This can affect production schedules. Identifying the right fit can minimize these setbacks. While there are many options, finding a compatible design often requires extra research and consideration.

In 2026, the CNC machining industry continues to innovate. Understanding the major types of CNC stoppers is crucial for precision. These specialized tools ensure accuracy in positioning and hold workpieces securely during milling or turning operations.

One common type is the fixed CNC stopper. This stopper limits movement in one direction, allowing for repeated accuracy. However, users must ensure proper calibration. A slight misalignment can lead to significant errors. Adjustable stoppers are versatile and can be fine-tuned, but they require careful adjustment and can complicate setups.

Another essential type is the pneumatic stopper. They use air pressure to clamp workpieces tightly. While effective for high-speed operations, they can be prone to failure if not maintained properly. Users should be aware of potential leaks. Additionally, magnetic stoppers provide quick setups and easy adjustments. Yet, they may struggle with heavy materials, leading to inconsistent performance. Understanding these types helps improve precision machining outcomes in 2026.

| CNC Stopper Type | Material | Precision Level | Common Applications | Max Load Capacity |

|---|---|---|---|---|

| Mechanical Stopper | Aluminum | ±0.01 mm | Milling, Drilling | 500 kg |

| Pneumatic Stopper | Steel | ±0.005 mm | Automotive Parts Assembly | 300 kg |

| Vacuum Stopper | Polymer | ±0.02 mm | Glass Handling | 150 kg |

| Hydraulic Stopper | Cast Iron | ±0.03 mm | Heavy Machinery | 1000 kg |

| Electronic Stopper | Plastic Composite | ±0.001 mm | High-Precision Electronics | 80 kg |

When choosing CNC stoppers for precision machining, several factors must be considered. The most significant aspect is the material quality. Common materials include steel, aluminum, and polymers. Each offers different durability and wear resistance, impacting the machining accuracy. A recent report highlighted that equipment with high tensile strength can improve overall machining precision by up to 25%.

The design of the stoppers plays a crucial role as well. Stoppers with adjustable features allow for flexibility in various machining operations. This adaptability can help minimize downtime, which is vital for productivity. Data suggests that businesses with customizable stoppers noted a 15% reduction in machining errors.

Tips: Always assess the compatibility of stoppers with your existing equipment. Seek expert recommendations if uncertain about specific needs. Regularly inspect your stoppers. Worn components can lead to costly errors.

Another important factor is the stopper's geometry. A well-designed stopper ensures stable clamping fluidity. Poorly designed stoppers can cause variations in the final product. A report found that variances can reach up to 3% in products, leading to increased waste rates. Continued education on stopper selection and trends can greatly enhance process efficiency.

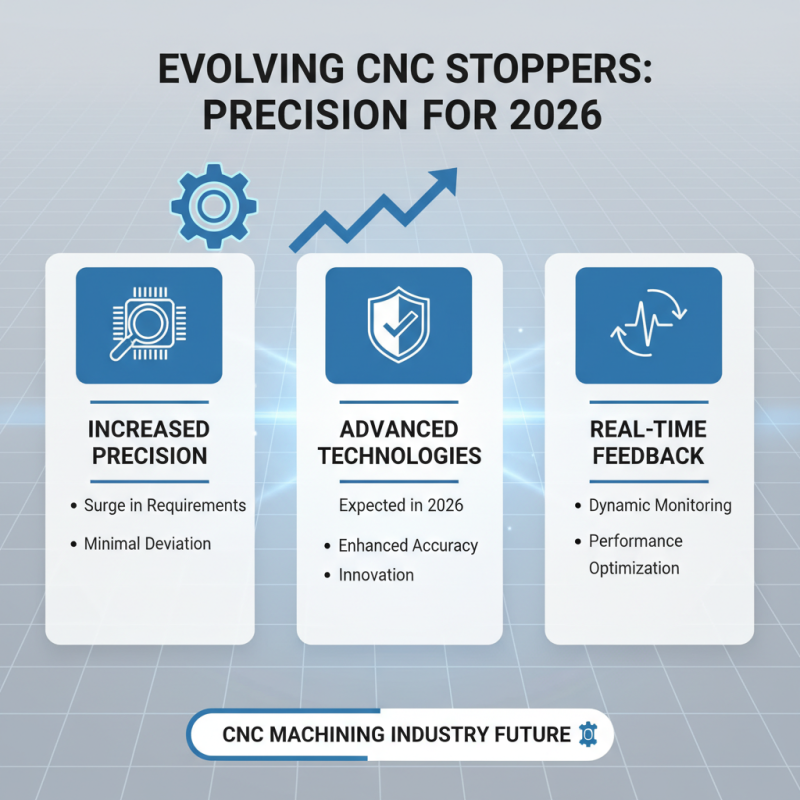

The CNC machining industry continues to evolve, particularly in the realm of stoppers. Recent reports indicate a surge in precision requirements. In 2026, CNC stoppers are expected to feature advanced technologies that enhance accuracy. One innovative feature is real-time feedback systems. These systems monitor performance dynamically, ensuring minimal deviation in machining processes.

Another trend is the integration of smart materials. These materials can adapt their properties based on environmental changes. For instance, temperature fluctuations may affect machining precision. Stoppers that respond to such changes can maintain tighter tolerances, improving overall production quality. Recent data suggests that machines using these advanced stoppers can increase efficiency by up to 30%.

However, implementing these technologies is not without challenges. Existing setups may struggle to fully leverage new features. Additionally, training workers to understand and utilize these advancements can be time-consuming. Companies must invest time in assessing whether the benefits of upgraded stoppers outweigh potential disruptions. Balancing innovation with practicality remains a key focus as the industry strives for excellence.

In 2026, precision machining relies heavily on CNC stoppers. Analyzing various brands helps identify what features lead the market. Key aspects include material quality, ease of adjustment, and overall durability. Each brand offers unique solutions, but not all can withstand rigorous usage.

When assessing CNC stoppers, consider the specific needs of your projects. Some stoppers excel in heavy-duty tasks, while others favor finesse. Evaluate performance through real-world applications. Observe any failures or inconsistencies. Reflecting on these insights can illuminate better choices.

Tip: Look for user reviews and testimonials. They provide real experiences that can guide purchasing decisions. Sometimes, popular options may not always fit specialized needs. Always prioritize quality over brand reputation.

Also, check for compatibility with your existing machines. A perfect match leads to smoother operations. Mismatched stoppers can cause delays and errors. Understand your equipment's tolerances for optimal performance.

This chart displays a comparative analysis of various CNC stoppers based on precision, durability, and user ratings. The data represents the performance metrics of leading CNC stopper models in 2026.