- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

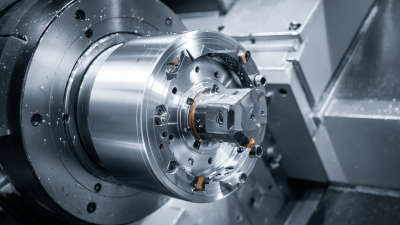

In the fast-evolving world of precision machining, selecting the right CNC insert is crucial. These inserts are vital components that influence the quality of the machined surface and overall productivity. Factors such as material type and cutting conditions heavily impact performance.

CNC inserts come in various shapes, sizes, and materials. Each serves distinct purposes. For instance, carbide inserts are common for their hardness and durability. However, they can be expensive and may not always offer the best edge retention in specific applications.

Machinists often face challenges when choosing the best CNC insert. Some may prioritize cost over performance. This might lead to issues like faster wear or inadequate finish quality. Finding the right balance between cost and effectiveness remains an ongoing dilemma. As technology advances, understanding these nuances becomes increasingly important for peak performance.

CNC inserts play a critical role in precision machining. These cutting tools are essential for achieving high accuracy and efficiency. The right inserts can enhance production quality and reduce costs. According to a recent industry report, tools can account for up to 30% of production costs. This underscores the need for investing in quality inserts.

Different materials affect performance. Carbide, ceramic, and high-speed steel (HSS) are popular choices. Each material has unique properties that impact tool life and machining speed. A study indicates that carbide inserts, for instance, can improve cutting speeds by 50% compared to HSS. However, the selection process can be quite complex.

Machinists must also consider the type of machining operation. Inserts suitable for turning may not be ideal for milling. Furthermore, the choice of coating can significantly alter performance. Despite the available options, many machinists still rely on outdated tools. There's a pressing need for ongoing education in tool selection. This can help bridge the gap between traditional practices and modern requirements.

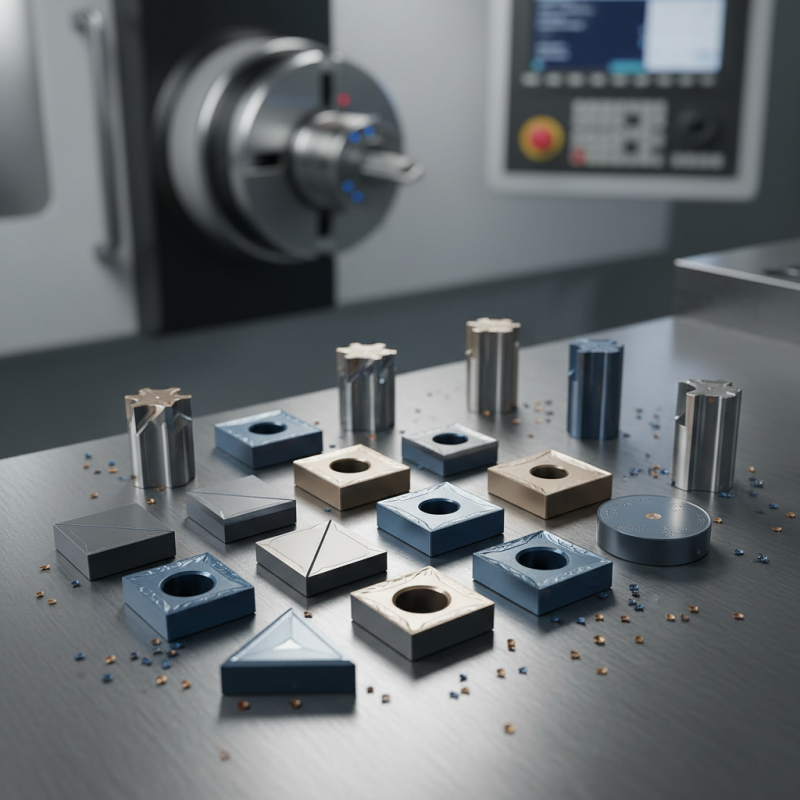

When choosing CNC inserts, different applications require specific types of inserts. For turning, consider inserts with sharp cutting edges. They effectively handle materials like aluminum and plastics. For milling operations, the geometry of the insert plays a crucial role. Inserts with positive rake angles often provide better surface finishes.

In drilling, carbide inserts are commonly favored for their durability. They can withstand high temperatures and maintain their edge longer. For less demanding tasks, coated inserts provide a cost-effective option. Note that the insert's coating can impact performance under various conditions.

**Tips:** Always match the insert type with your material. Check compatibility before making a purchase. Also, consider the cutting speed. It can be an important factor for achieving precision.

Some users may find it challenging to choose the right inserts. Experimentation might lead to trial and error. Keeping detailed records of your machining conditions can help refine your choices over time. Balancing tool wear and cut quality requires ongoing assessment.

| Insert Type | Material | Application | Coating | Average Tool Life (Hours) |

|---|---|---|---|---|

| Carbide Inserts | Carbide | General Machining | TIAlN | 50 |

| Ceramic Inserts | Ceramic | Hard Material Machining | None | 80 |

| CBN Inserts | Cubic Boron Nitride | Hard Machining | CVD | 100 |

| PCD Inserts | Polycrystalline Diamond | Non-Ferrous Materials | None | 150 |

| HSS Inserts | High-Speed Steel | General and Finishing Operations | None | 30 |

Selecting CNC inserts for precision machining involves various factors that can significantly affect output quality. Material type is a primary consideration. For example, hard materials like titanium require tougher inserts, while softer materials allow for different geometries. A recent industry report indicates that 75% of manufacturers find material compatibility impacts tool life directly.

Cutting edge geometry also plays a critical role. Inserts with unique shapes can enhance performance. A U.S. machining study found inserts with ​modified geometries increased feed rates by 25%. However, choosing the wrong angle can create issues, such as increased wear or poor surface finishes.

Durability and wear resistance are essential for maintaining productivity. According to market analytics, up to 30% of machining costs stem from tool wear. It's crucial to assess various coating technologies. Some coatings can extend tool life, while others might not perform as expected. Evaluating the right combination of features is a significant challenge.

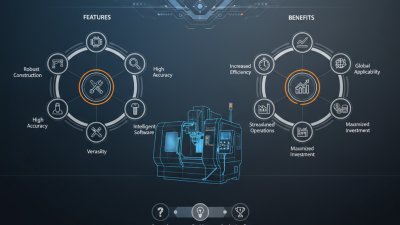

This chart illustrates the performance ratings of various CNC insert materials, highlighting their effectiveness in precision machining. The ratings are based on durability, cutting speed, and application versatility.

When it comes to precision machining, CNC inserts play a crucial role. In 2026, there are many top CNC insert models worth considering. Each model brings unique features tailored for different applications. These inserts can handle various materials, from metals to plastics. The right choice can significantly enhance cutting efficiency.

Choosing an insert requires careful consideration. Pay attention to the material grade. Not all inserts suit every machining task. Factors like hardness and toughness influence performance. Experimenting with different models may lead to surprising improvements. Sometimes, what seems best on paper might not perform as expected.

Tips for selecting CNC inserts include understanding your machine’s capabilities. Know your spindle speed and feed rate. Insert geometry is equally important; it affects chip removal and surface finish. Regularly check wear and tear to make informed adjustments. Reviewing this data can guide you in making better choices.

As we look to 2026, CNC insert technology evolves rapidly. The future is increasingly driven by automation and data analysis. These technologies promise higher precision and efficiency. Operators often find it challenging to adapt to these changes. However, embracing new technology is essential for staying competitive.

Advanced materials are emerging in CNC inserts. These materials improve longevity and performance under various conditions. But, selecting the right insert remains complex. Users need training to understand these innovations fully. There are instances where traditional inserts still perform better. It’s not always about the newest solution.

Sustainability is another trend. The industry is shifting towards eco-friendly materials. This can lead to questions about performance versus environmental responsibility. Proper balancing of these factors is critical. Every innovation may not suit every application, and that's where the challenge lies. The journey towards improvement is continuous and requires thoughtful consideration.