- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

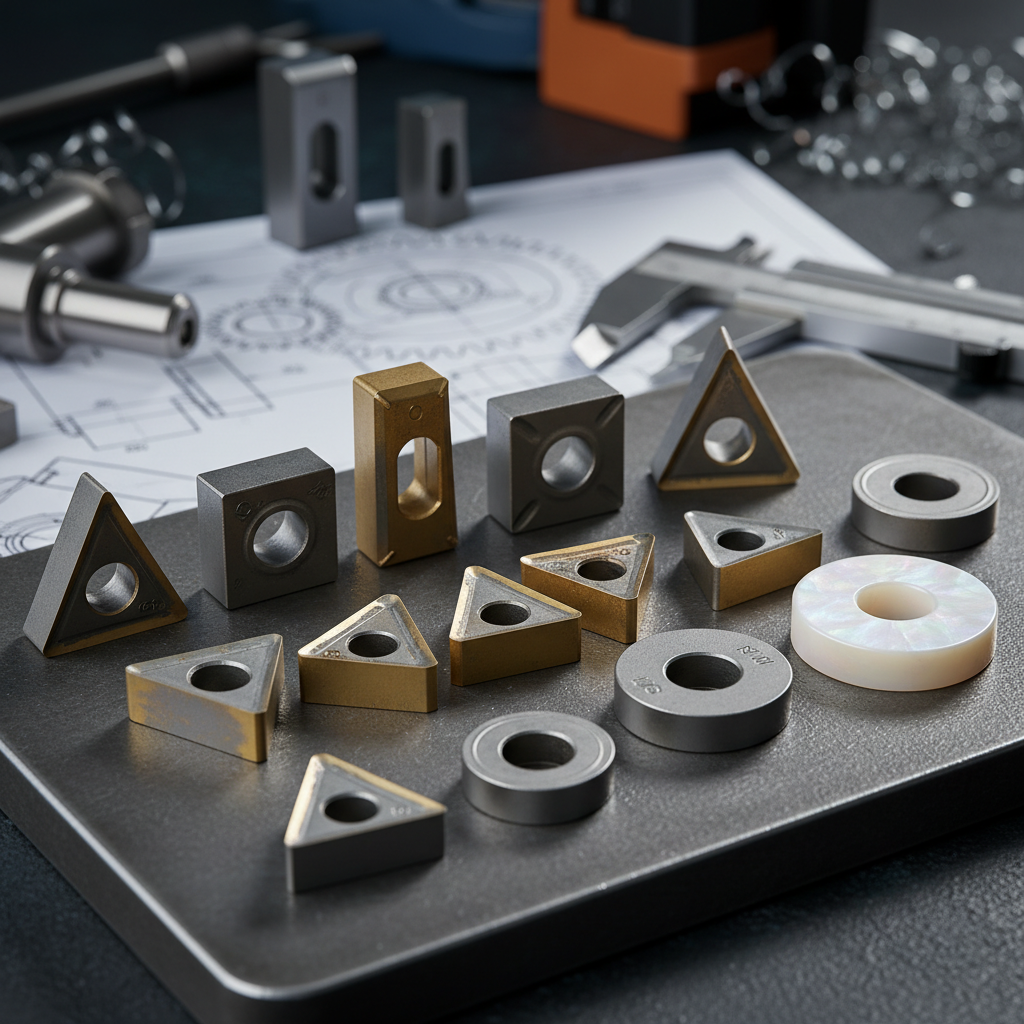

In the world of precision machining, selecting the right CNC insert is crucial for achieving optimal performance and efficiency. As the manufacturing industry continues to evolve, understanding the characteristics and applications of different CNC inserts can significantly enhance productivity and part quality. This guide aims to provide valuable insights into the various factors to consider when choosing CNC inserts, ensuring that you make informed decisions tailored to your specific machining needs.

From material types to coatings and geometries, each aspect of CNC inserts plays a vital role in their performance during the machining process. With the right insert, you can improve cutting speeds, reduce tool wear, and achieve superior surface finishes. In this guide, we will delve into expert tips and practical advice on how to identify the best CNC insert for your applications, taking into account your machining environment and desired outcomes. By following these guidelines, you can optimize your machining performance and stay ahead in a competitive landscape.

Understanding CNC inserts is essential for optimizing machining performance. There are various types of CNC inserts, including carbide inserts, ceramic inserts, cermet inserts, and others, each designed for specific applications in drilling, milling, and turning. For instance, carbide inserts are preferred for their wear resistance and toughness, making them suitable for machining tough materials like EN24 grade alloy steel. Recent studies show that cryogenic treatment enhances the performance of these inserts, resulting in better surface finish and increased tool life.

When selecting CNC inserts, consider their application and material compatibility. Tips for choosing the right insert include evaluating the workpiece material, assessing the required cutting speed and feed rate, and understanding the insert geometry, which influences chip flow and heat dissipation. The indexable milling cutters market is projected to grow significantly, reaching USD 9.6 billion by 2035, showcasing the growing demand for innovative cutting tools and the importance of selecting the right inserts for specific machining tasks.

Furthermore, advancements in insert designs, like those introduced recently, cater to a broader range of applications across various sectors, emphasizing the need to stay updated with industry trends. Selecting the appropriate insert can significantly impact machining efficiency and costs, making it a critical decision in the manufacturing process.

Choosing the right CNC inserts is crucial for achieving optimal machining performance and efficiency. Several factors influence this selection process, starting with the material being machined. For instance, different materials such as aluminum, steel, or titanium require specific insert geometries and coatings that enhance cutting performance and tool life. Understanding the workpiece material’s properties can help in selecting inserts that can endure the operational stresses while maintaining integrity.

Additionally, the cutting conditions play a significant role in insert selection. Variables such as cutting speed, feed rate, and depth of cut must be carefully analyzed to choose inserts that can perform well under specific conditions. High cutting speeds may demand inserts with advanced coatings to reduce wear, while lower speeds may benefit from broader inserts to improve material removal rates. Lastly, the machine capabilities should also be considered; not all machines can accommodate the same inserts, so ensuring compatibility with the CNC machine tools is vital for ensuring seamless operation and enhanced machining efficiency.

| Insert Material | Coating Type | Workpiece Material | Cutting Speed (m/min) | Feed Rate (mm/rev) | Tool Geometry | Expected Tool Life (hours) |

|---|---|---|---|---|---|---|

| Carbide | TiN | Steel | 150 | 0.2 | Rake Angle: 5° | 20 |

| Ceramic | TiAlN | Cast Iron | 200 | 0.15 | Rake Angle: 10° | 30 |

| Cermet | AlTiN | Aluminum | 120 | 0.25 | Rake Angle: 5° | 25 |

| High-Speed Steel | None | Plastic | 70 | 0.5 | Rake Angle: 15° | 15 |

Choosing the right CNC inserts for optimal machining performance involves understanding the performance characteristics of various insert materials. Recent advancements have brought new carbide grades to the forefront, specifically designed for turning applications. These new materials enhance performance for specific metal types, like ISO-P steels, which are prevalent in many machining environments. The incorporation of advanced coatings further boosts the wear resistance of these inserts, enabling them to remove more material while maintaining higher machining speeds.

**Tips for Selecting CNC Inserts:**

1. Consider the material compatibility of the insert, especially when working with specialty alloys or composites, to ensure the best performance and longevity.

2. Look for inserts with coatings that suit your application, as this can greatly improve performance and reduce wear.

3. Evaluate the toughness of the insert grade for your specific machining conditions; tougher insert grades are beneficial for applications involving continuous cutting or challenging materials.

By taking these characteristics into account when selecting CNC inserts, machinists can significantly enhance their machining efficiency and overall output quality.

Maintaining CNC inserts for longevity is crucial to ensuring optimal machining performance. One of the best practices is to implement a regular inspection schedule. By routinely checking for wear, breakage, or build-up of cutting materials, operators can replace or service inserts before they compromise machining quality. Early detection of issues not only prolongs the life of the inserts but also enhances the overall efficiency of the machining process.

Proper lubrication also plays a vital role in maintaining the life of CNC inserts. Using the right cutting fluids helps reduce friction and dissipates heat, which can significantly affect the performance of the inserts. Furthermore, selecting the appropriate speed and feed rates for the specific material and insert type can minimize unnecessary wear. Adjusting machining parameters based on material characteristics ensures that the inserts operate within their optimal performance range, preventing premature degradation.

As we approach 2025, the landscape of CNC inserts technology is evolving rapidly, driven by advancements in materials and coatings that enhance machining performance. According to a recent report by MarketsandMarkets, the global CNC tools market is expected to reach $7.62 billion by 2025, growing at a CAGR of 5.7%. This growth is largely attributed to the increasing demand for high-precision machining in various sectors, including aerospace and automotive.

One of the most notable trends is the rise of ceramic and cermet inserts, which offer superior hardness and thermal resistance compared to traditional carbide inserts. A study from ResearchAndMarkets highlighted that the share of ceramic inserts in the CNC tools market is projected to rise significantly, as they are increasingly utilized for high-speed machining applications. Furthermore, advancements in PVD (physical vapor deposition) coatings are enabling these inserts to achieve longer tool life and improved surface finish, making them a preferred choice for manufacturers focusing on efficiency and cost-effectiveness.

Another emerging trend is the integration of smart technologies in CNC machining processes, including the use of IoT (Internet of Things) for real-time monitoring and predictive analytics. This shift is expected to optimize the tool lifecycle and reduce downtime, with a recent survey indicating that over 60% of manufacturers are considering smart features for their CNC machines by 2025. As these technologies continue to converge, manufacturers will have the opportunity to choose CNC inserts that not only meet their machining needs but also contribute to a more intelligent manufacturing environment.